Control Unit Structure of Motorcycle Anti-skid Braking System

A system control unit, anti-skid brake technology, applied in the direction of bicycle brakes, brakes, bicycle accessories, etc., can solve the problems of poor brake feel, too long oil pipe, long oil pipe 14, etc., to improve the brake feel and use Efficacy, the effect of shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make it easier for your examiners to understand the structure of the present invention and the effects it can achieve, the accompanying drawings are hereby described as follows;

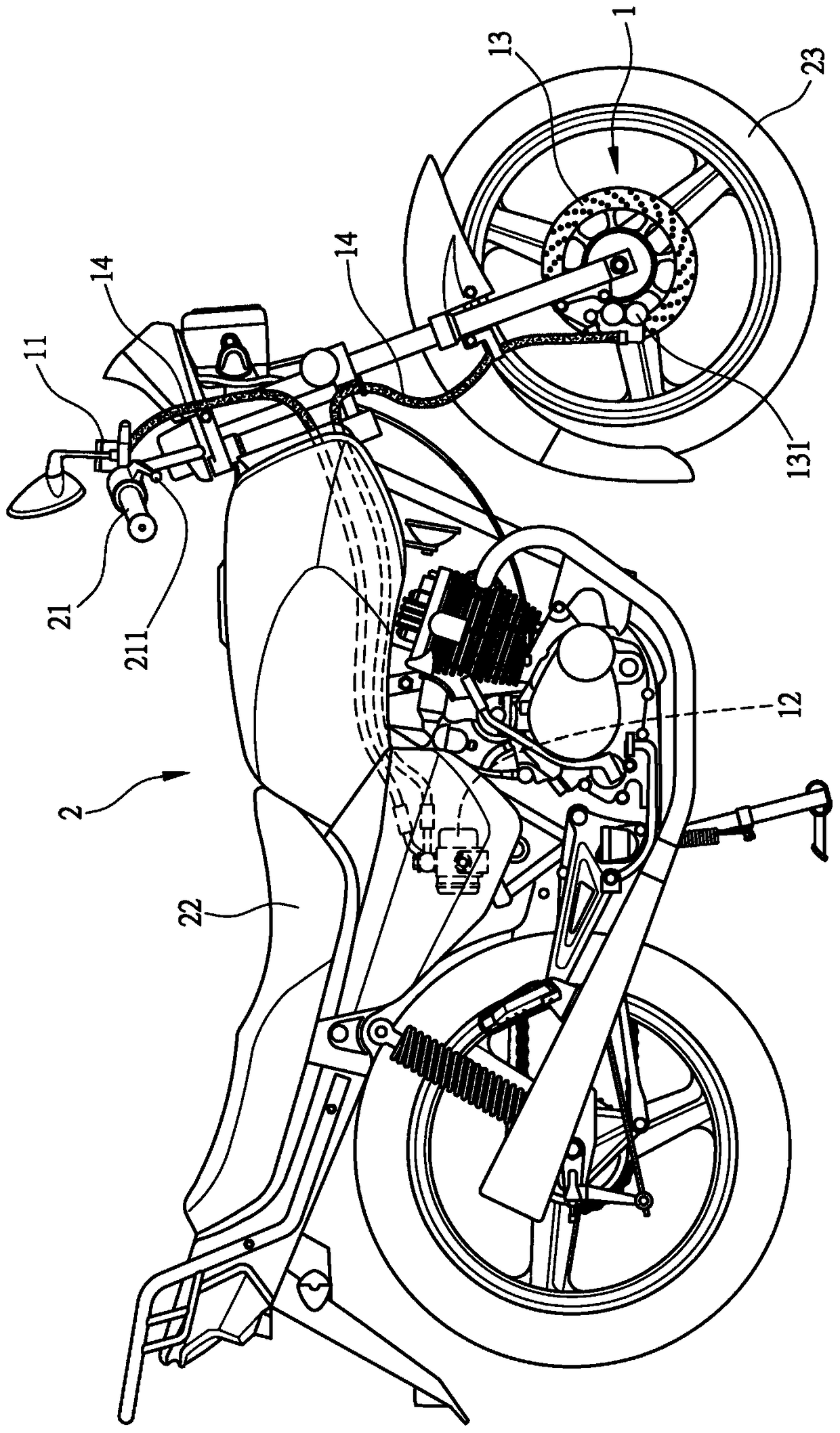

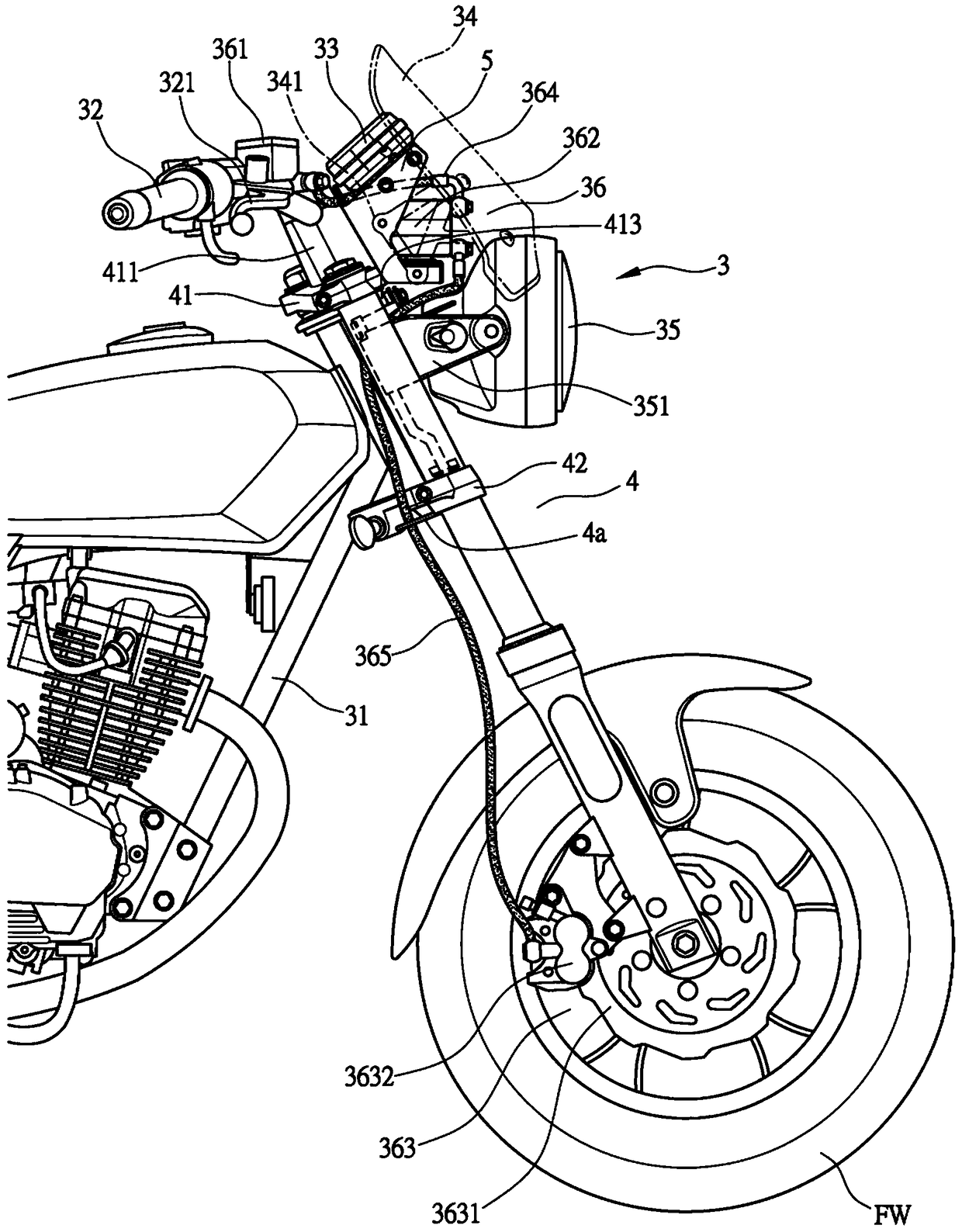

[0017] First, see figure 2 As shown, the front fork group 4 is connected to the front of the frame unit 31 of the motorcycle 3 (especially a straddle type motorcycle), and the front fork group 4 has an upper connecting plate 41 and a lower connecting plate 42. The steering handle 32 is arranged on the plate 41 , and the front wheel FW is pivotally arranged at the lower end of the front fork set 4 .

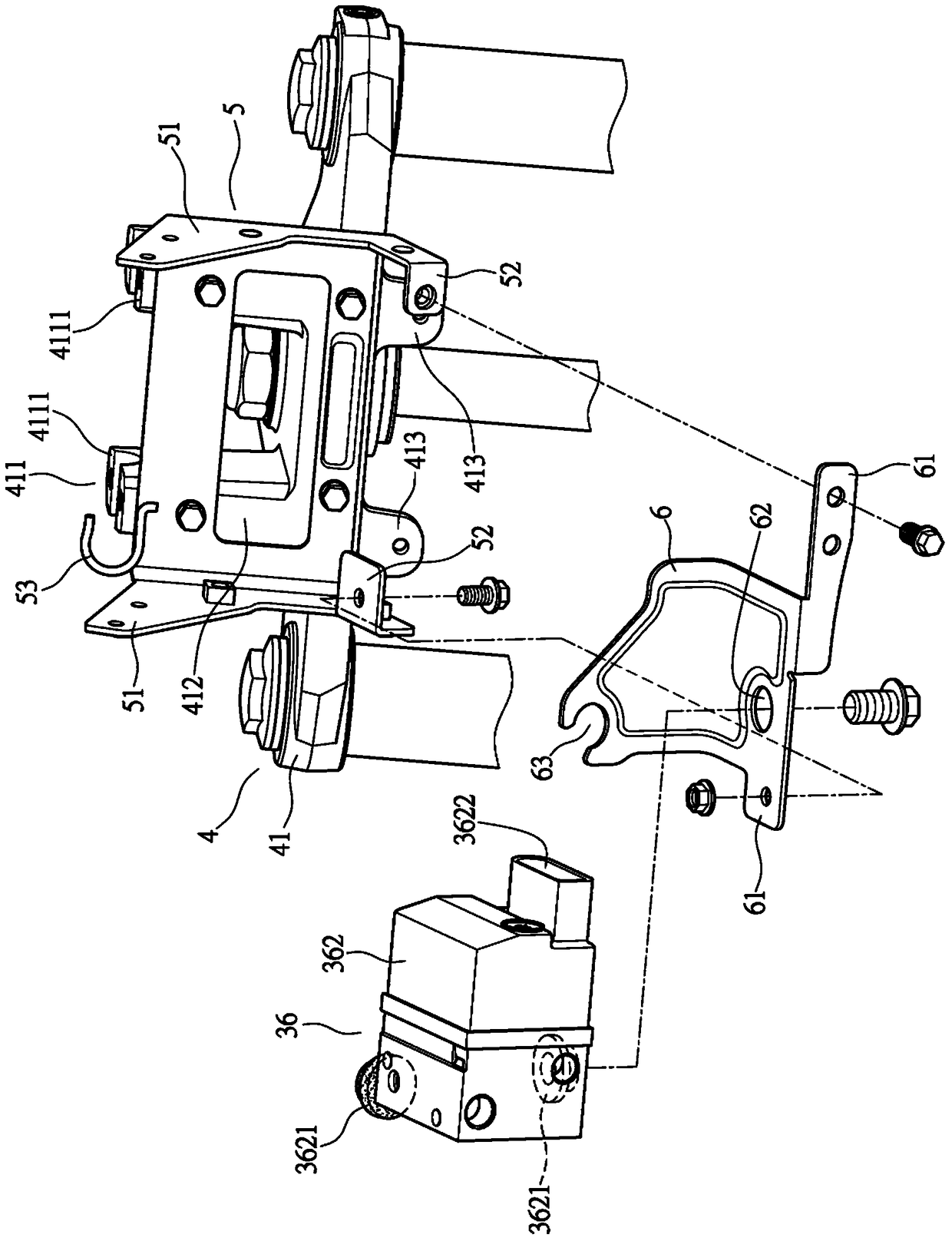

[0018] Such as figure 2 , 3 As shown, the upper connecting plate 41 is provided with a connecting portion 411 protruding toward the top of the motorcycle 3, and a steering handle connecting platform 4111 is arranged above the connecting portion 411, and the steering handle 32 is arranged on the steering handle connecting platform 4111. The upper connecting plate 41 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com