Complete desulfurization system of small boiler

A desulfurization system, small boiler technology, applied in the directions of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of occupation, large space, clogging of grooves or pipelines, etc., to achieve energy saving and good construction conditions , the effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

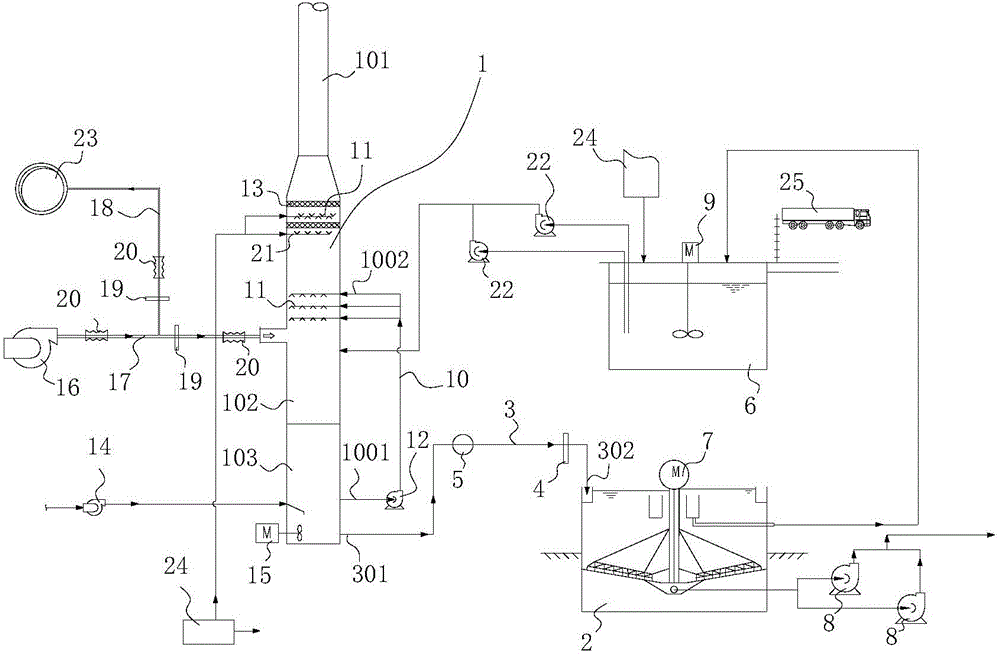

[0036] Such as Figure 1-8 As shown, a small boiler complete desulfurization system, including absorbent preparation system and SO 2 absorption system, the SO 2 The absorption system includes an absorption tower 1, which is provided with a mist eliminator 13, and the SO 2 The absorption system includes a sedimentation tank 2, the sedimentation tank 2 is connected to the absorption tower 1 through a siphon pipeline 3 bent upwards in the middle section, and the siphon inlet port 301 of the siphon pipeline 3 is connected to the lower part of the absorption tower 1, and the siphon pipeline The siphon outlet port 302 of 3 is located above the sedimentation tank 2 . The siphon principle is used here, that is to say, the liquid level at the siphon inlet port 301 is higher than the liquid level at the siphon outlet port 302 described above. In this way, the liquid in the lower part of the absorption tower 1 can flow to the sedimentation tank 2 without energy consumption due to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com