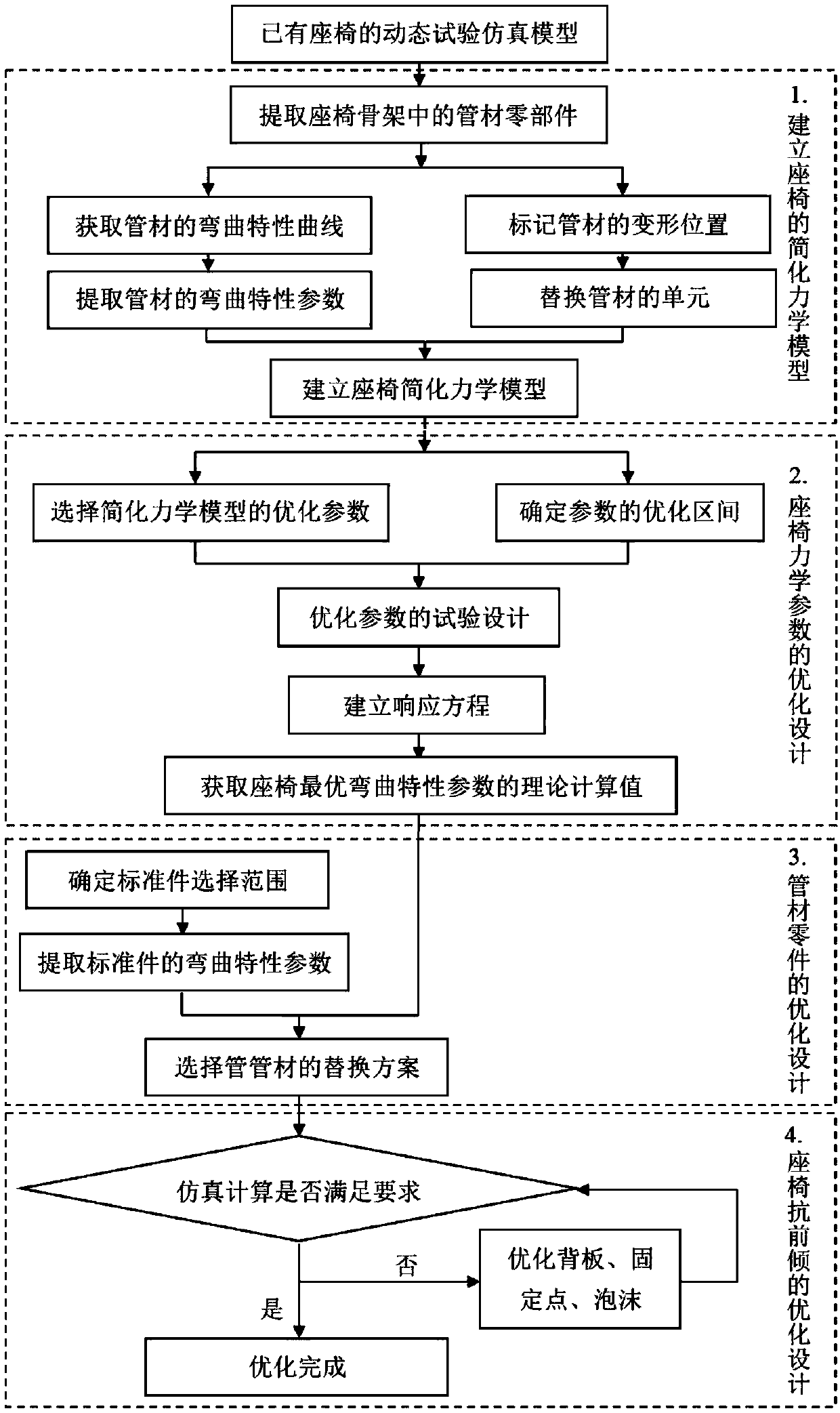

An optimal design method for the anti-tilt performance of student seats on special school buses

An optimized design and seat technology, which is applied in the field of school bus collision safety, can solve the problems of design blindness, repeated modeling and long calculation time, and achieve the effect of reducing data scale, facilitating large-scale calculations, and less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

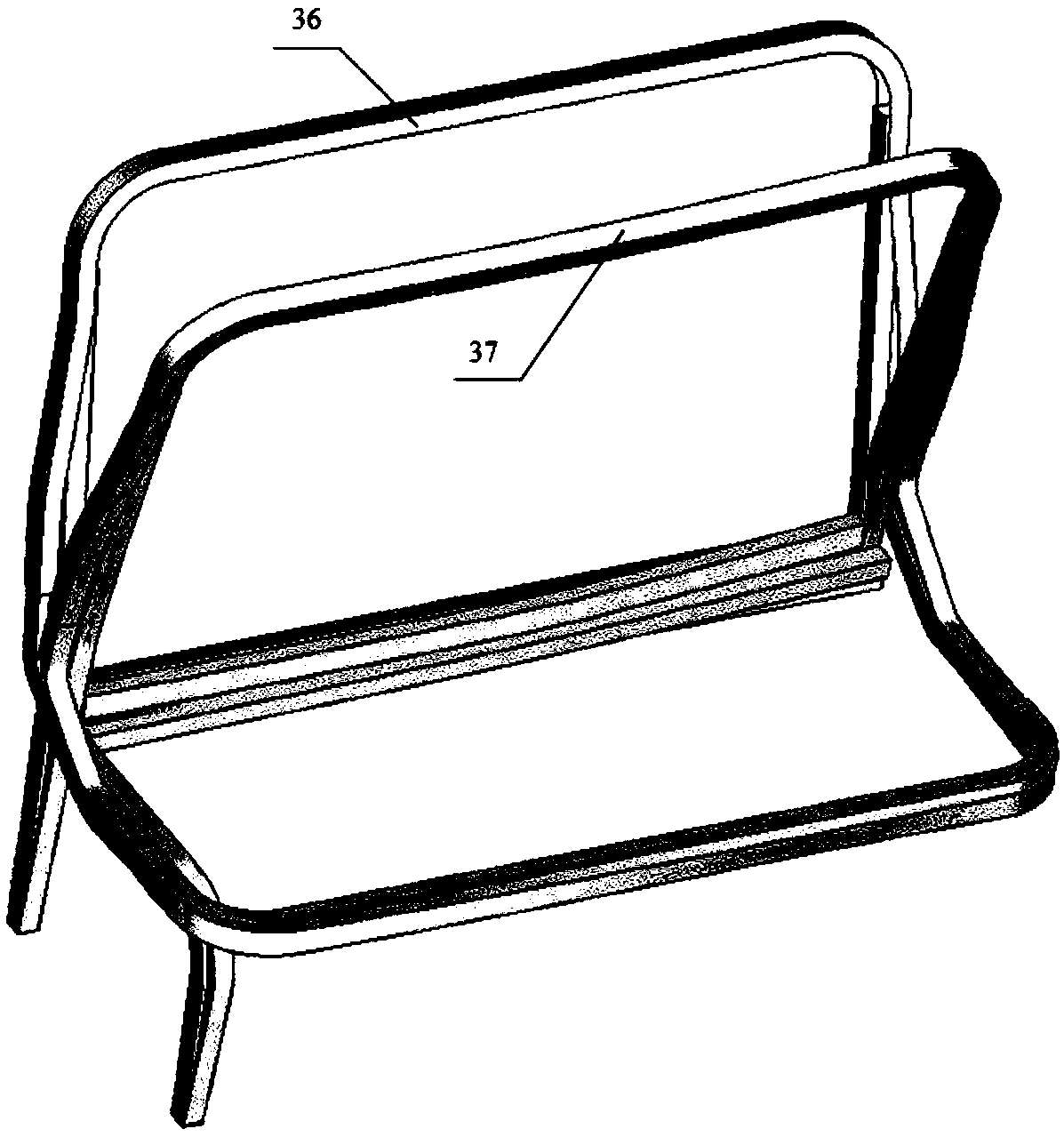

[0108] In this implementation case, a long three-seater school bus seat for primary and secondary schools is used as the optimization design object. The injury index of this seat exceeds the limit value in the two dummies without seat belt restraints. , the existing seat simulation model is established by Ls-dyna software. On the basis of the existing dynamic test simulation analysis model of the seat, the optimal design method of the present invention is used to optimize the anti-tilt performance of the seat. In this embodiment, first control the thickness of the backboard between 1.0mm-2.0mm and the thickness of the backrest foam between 10mm-30mm, and then change the thickness of the fixed connector in the skeleton to 1.5mm -4.0mm, so that the occupant's injury evaluation index value in the simulation results meets the regulatory requirements.

[0109] 1. Establish a simplified mechanical model of the seat

[0110] refer to figure 2 and image 3 , extract the metal pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com