Improved plastic mixing device capable of automatically measuring weight

A mixing device and weighing technology, which is applied in the field of plastic mixing devices that can automatically measure weight, can solve the problems that materials are easy to get stuck at the feeding port, difficult to push, and affect the mixing efficiency of plastics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

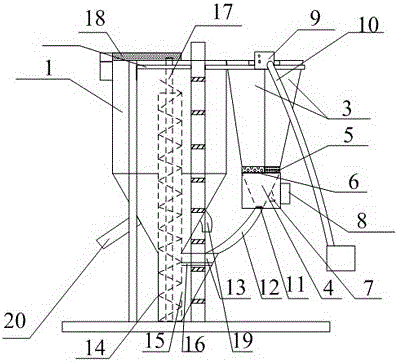

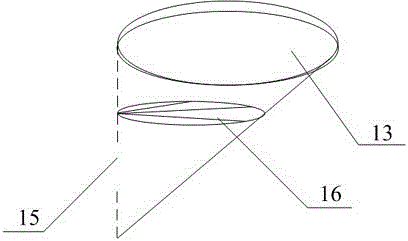

[0026] Such as figure 1 An improved plastic mixing device capable of automatic weighing is shown, including a mixer barrel 1 and a mixer support 2, the mixer barrel 1 is fixed on the mixer support 2, and a weighing barrel is also fixed on the mixer support 2 , the weighing barrel is a funnel-shaped structure with a wide top and a narrow bottom. There are two weighing storage hoppers 3 and a weighing hopper 4 inside the barrel. The weighing hopper 4 is located in the two weighing storage hoppers. At the bottom of 3, there is an A metering valve 5 and a B metering valve 6 in the middle of the weighing hopper 4 and the weighing storage hopper 3, and the metering valve controls the switch of the channel between the weighing storage hopper 3 and the weighing hopper 4; A weight sensor 7 is set on the weighing bucket 4, and the weight sensor 7 is connected with a display controller 8 located outside the weighing barrel; an air suction motor 9 is also fixed on the weighing barrel, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com