Air inlet valve capable of producing inlet air swirls and provided with spiral groove, and internal combustion engine

A technology of spiral grooves and intake valves, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as easy partial wear of valves, large intake resistance, and poor sealing, so as to improve fuel economy and emission performance , meet the power and economy, improve the effect of gasoline evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

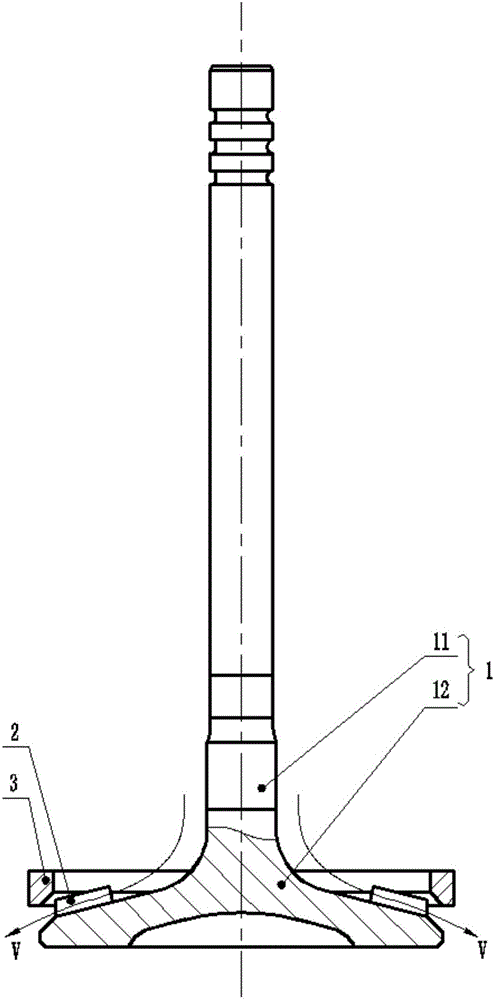

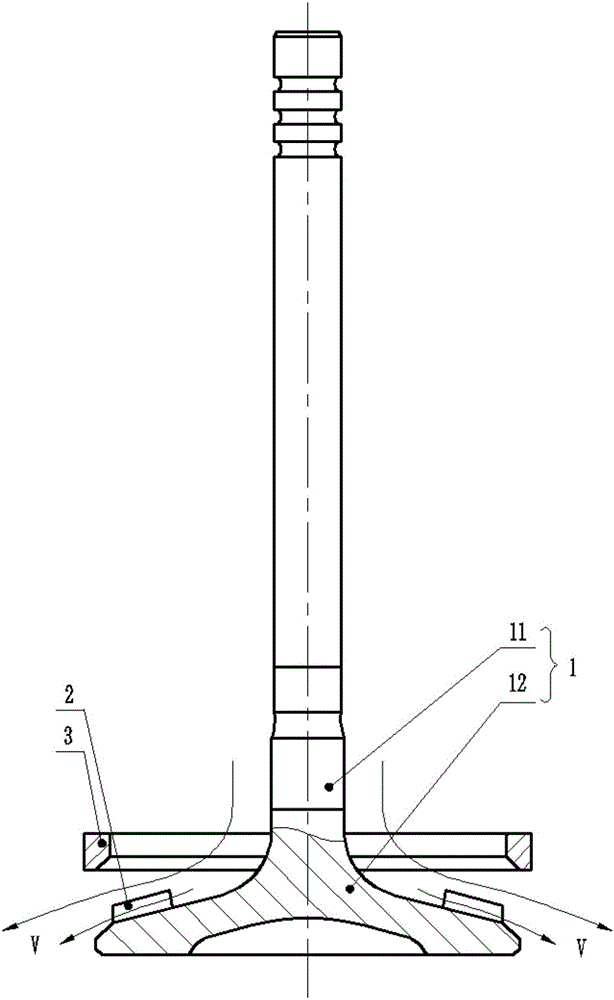

[0022] On the one hand, the present invention provides an intake valve 1 with a spiral groove that generates an intake swirl, such as Figure 1 to Figure 4 As shown, it includes a valve stem 11 and a valve disc 12 , and the back of the valve disc 12 is provided with a plurality of arc-shaped deflectors 2 that are curved in the same direction to make the intake airflow form a vortex.

[0023] The back side of the valve disk 12 of the intake valve 1 with spiral grooves 1 that produces the intake vortex of the present invention is provided with a plurality of arc-shaped deflectors 2 with the same bending direction, and a spiral shape is formed between the deflectors 2 and the valve disk 12. groove. When the intake valve 1 is at a small lift, the intake air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com