Automatic control method for automatic screw feeding equipment

A screw, linear vibration technology, applied in metal processing equipment, manufacturing tools, metal processing and other directions, can solve problems such as equipment efficiency cannot be guaranteed, and achieve the effect of saving labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described.

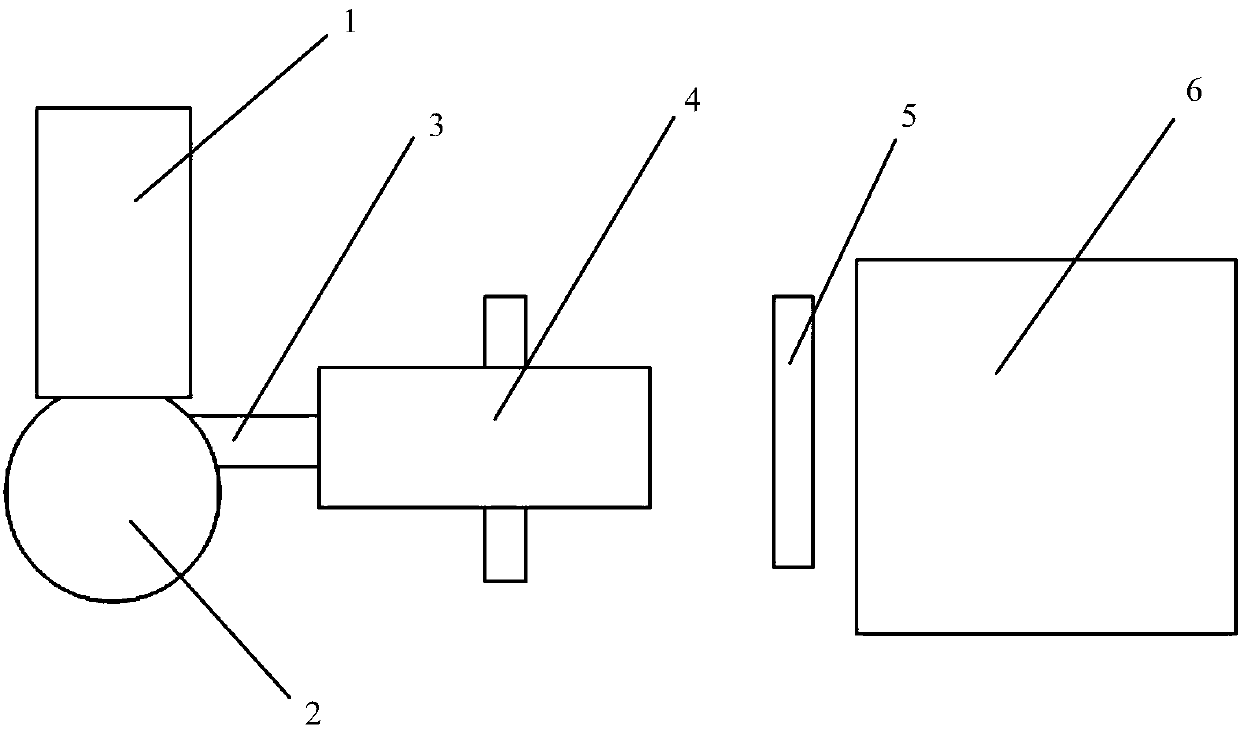

[0014] Such as figure 1 As shown, the present invention provides a kind of automatic control method of automatic screw rod equipment,

[0015] The automatic screw release equipment used in the method includes a feed bin 1, a disc conveying feeder 2, a linear vibrating guide rail 3, a pre-assembly mechanism 4, and a placement mechanism 5. The placing mechanism includes n jaw cylinders and two cylinders, one cylinder is used for the upward and downward movement of the jaw cylinder, and the other cylinder is used for the lateral movement of the jaw cylinder.

[0016] The silo 1 is transported to the disc conveying feeder 2 through the conveyor, and the linear vibrating guide rail 3 receives the screw from the exit of the disc conveying feeder 2; Line up on the vibrating guide rail 3.

[0017] Provide a pre-assembly mechanism 4 including pneumatic grippers th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com