Simple and convenient method for improving performance of on-line recycling membrane closed system for rinsing wastewater of tin-plating

A closed-system and resource-based technology is applied in the field of improving the performance of the closed system of the membrane method for on-line recycling of tin-plating rinsing wastewater, which can solve the problems of secondary pollution of waste liquid and the need to stop for cleaning, saving economic costs and preventing the formation of complex pollution. , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

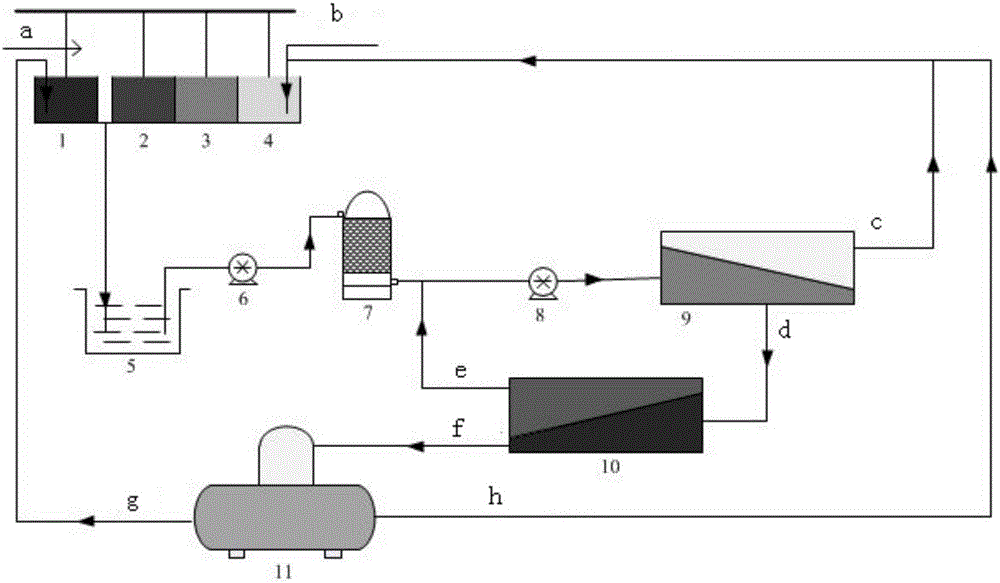

Image

Examples

Embodiment 1

[0026] Amino trimethylene phosphonate sodium crystals are added to the regulating tank in the closed system of tin plating rinse wastewater online resource recycling membrane method. After the addition, the concentration on the thick side of the film in the system is 1.0 ppm. The complex physical and chemical polymerization process of the four components of phenolsulfonic acid, dihydroxydiphenyl sulfone and sodium butylphenylphenolsulfonate, especially breaks the core role of phenolsulfonic acid, prevents the formation of inorganic and organic compound pollution, and maintains a high level for a long time The membrane flux can improve the performance of the closed system of membrane method for online recycling of tin-plating rinsing wastewater, and reduce the economical operation cost.

[0027] Implementation effect of this embodiment:

[0028] 1. The additive sodium aminotrimethylene phosphonate can inhibit the complex physical and chemical polymerization process of the four ...

Embodiment 2

[0033]Amino trimethylene phosphonate sodium solution is added to the electroplating tank in the closed system of tin plating rinse wastewater online resource recycling membrane method. After adding, the concentration on the film thick side in the system is 50.0ppm. The complex physical and chemical polymerization process of the four components of phenolsulfonic acid, dihydroxydiphenyl sulfone and sodium butylphenylphenolsulfonate, especially breaks the core role of phenolsulfonic acid, prevents the formation of inorganic and organic compound pollution, and maintains a high level for a long time The membrane flux can improve the performance of the closed system of membrane method for online recycling of tin-plating rinsing wastewater, and reduce the economical operation cost.

[0034] Implementation effect of this embodiment:

[0035] 1. The additive sodium aminotrimethylene phosphonate can inhibit the complex physical and chemical polymerization process of the four components ...

Embodiment 3

[0040] Amino trimethylene phosphonate sodium solution is added to the regulating tank in the closed system of tin plating rinse wastewater online resource recycling membrane method. After the addition, the concentration on the film thick side in the system is 100.0ppm. The complex physical and chemical polymerization process of the four components of phenolsulfonic acid, dihydroxydiphenyl sulfone and sodium butylphenylphenolsulfonate, especially breaks the core role of phenolsulfonic acid, prevents the formation of inorganic and organic compound pollution, and maintains a high level for a long time The membrane flux can improve the performance of the closed system of membrane method for online recycling of tin-plating rinsing wastewater, and reduce the economical operation cost.

[0041] Implementation effect of this embodiment:

[0042] 1. The additive sodium aminotrimethylene phosphonate can inhibit the complex physical and chemical polymerization process of the four compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com