Cleaning device for painting pen

A cleaning device and brush technology, applied in the direction of brushes and the like, can solve the problems of poor cleaning effect, poor practicability, and single cleaning method, and achieve the effects of improving drying efficiency, easy storage, and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

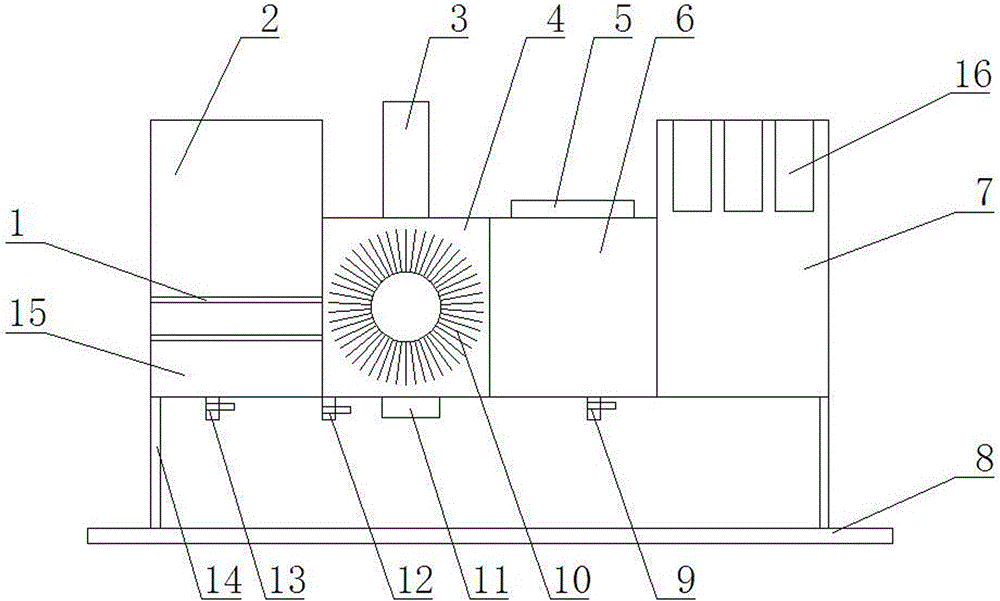

[0014] Such as figure 1 Shown, a kind of lacquer painting brush cleaning device comprises cylinder body 15, support frame 14, seat plate 8, and described cylinder body 15 bottom is installed on seat plate 8 by support frame 14; 2. The scrubbing cylinder 4, the cleaning cylinder 6, and the airing cylinder 7 are composed of the rinsing cylinder 2, the brushing cylinder 4, the cleaning cylinder 6, and the airing cylinder 7, which are connected from left to right; The surface is hollowed out, and the upper and lower layers of filter screens 1 are installed inside; the pen tube 3 is installed at the top of the brushing tube 4, the brush device 10 is installed inside, the brush motor 11 is installed at the bottom, and the brush motor 11 is connected to the brush device 10; Describe the cylinder tube 5 installed on the top of the cleaning tube 6; a plurality of drying pen fixing tubes 16 are installed on the upper end of the drying tube 7.

Embodiment 2

[0016] Such as figure 1 As shown, the filter screen 1 is a stainless steel metal filter screen 1.

Embodiment 3

[0018] Such as figure 1 As shown, the first drainpipe 13 with a control valve at the bottom of the rinsing cylinder 2; the second drainpipe 12 with a control valve at the bottom of the scrubbing cylinder 4; the bottom of the cleaning cylinder 6 Install a third drain 9 with a control valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com