A quick plug-in test millimeter wave connector

A connector, millimeter wave technology, applied in the direction of connection, connecting device components, coupling devices, etc., can solve the problems of signal distortion, unusability, signal leakage, etc., to prevent signal leakage, avoid leakage, and achieve the effect of good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

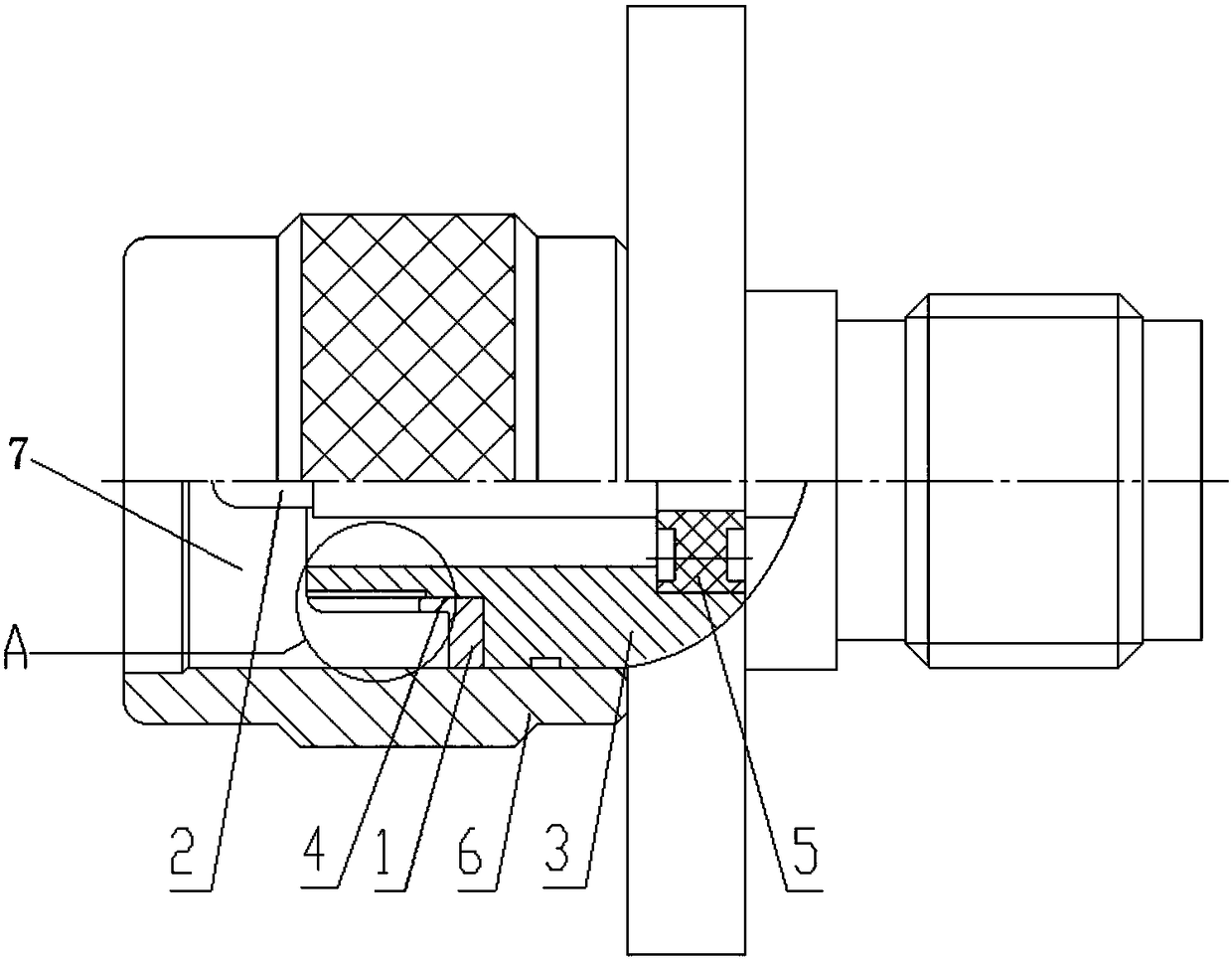

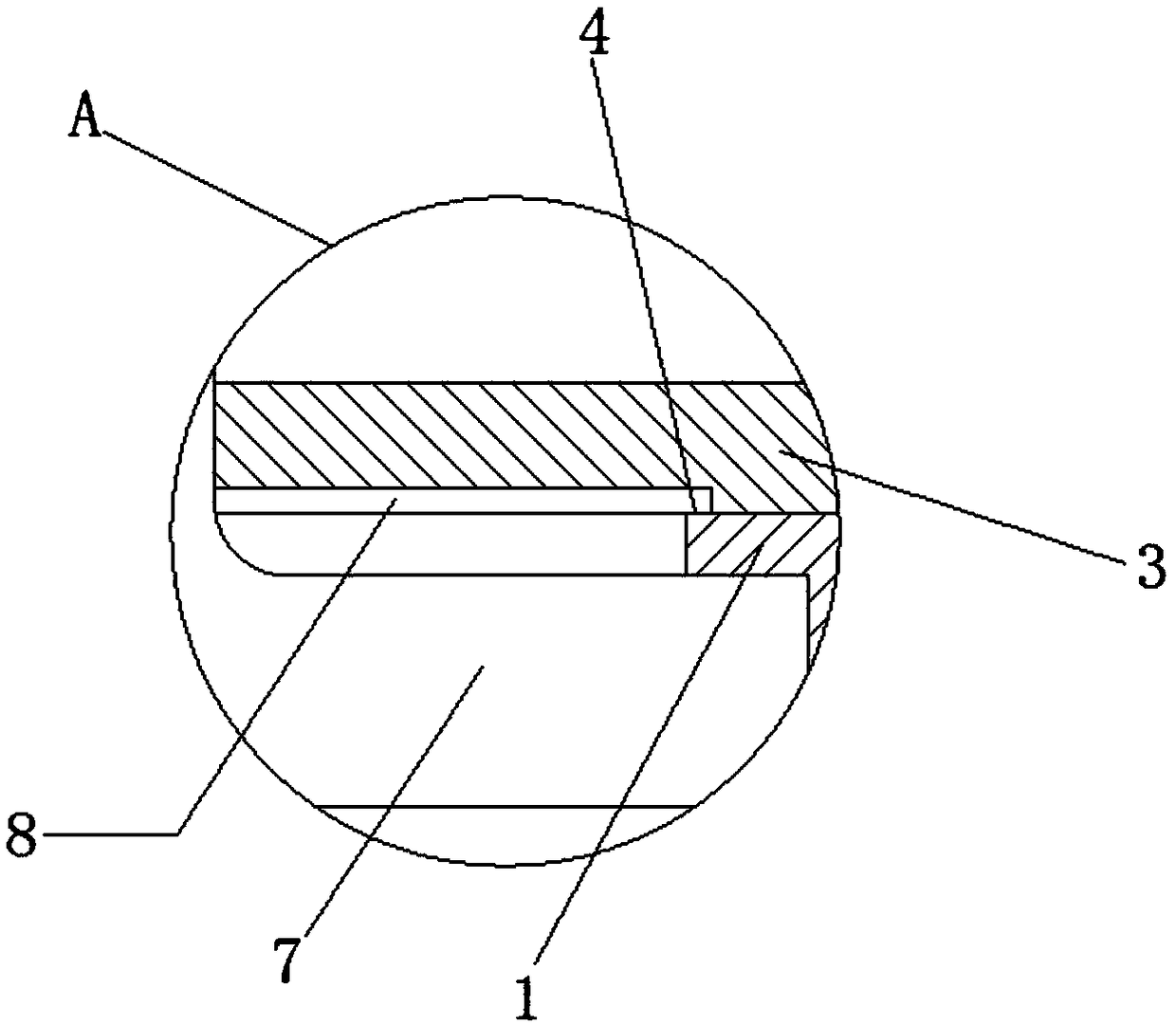

[0021] The present invention provides a millimeter-wave connector for quick plug-in testing, such as figure 1 As shown, it includes a connector body, one end of the connector body is set as a quick-insert structure, and the quick-insert structure includes a first shell 3, a pin 2 is arranged inside the first shell 3, and an insulating support medium 5 is set on the periphery of the pin 2 , the insulating support medium 5 supports the contact pin at the center of the first shell 3, so that the contact pin 2 does not contact the first shell 3; the first shell 3 is press-fitted in the second shell 6, and the first shell 3 and the second shell 6 A contact head 1 is provided between the two housings 6, and several split grooves are arranged on the contact head 1; a gap 8 is provided between the contact head 1 and the first housing 3; the pin 2 is inserted into the air mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com