Fast positioning device for center of precision shaft-like workpiece and detecting method

A technology for workpiece centering and positioning devices, applied to measuring devices, optical devices, instruments, etc., can solve the problems of difficulty in feature point collection, low detection efficiency, and poor detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

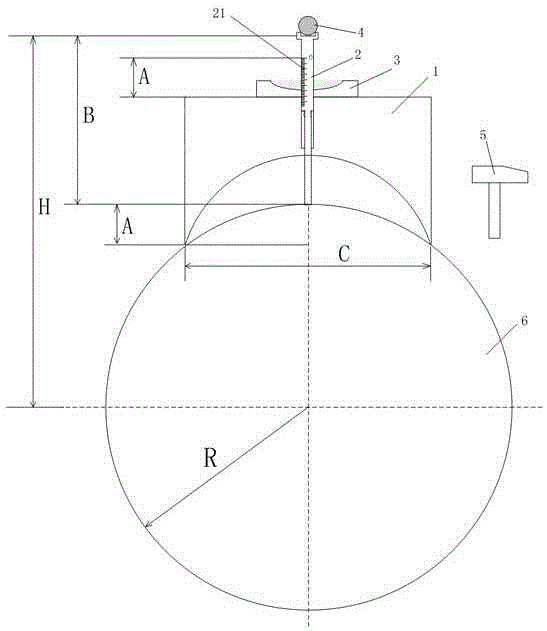

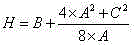

[0016] Example figure 1 As shown, the rapid center positioning device for precision shaft workpieces of the present invention includes an arched base 1, a centering rod 2, a level 3 and a target ball 4, and the centering rod 2 passes through the center of the arched base 1 and moves Cooperate, the bottom surface of the arched base 1 is on the same plane as the bottom end of the center positioning rod 2, the target ball 4 is arranged on the top surface of the center positioning rod 2, and the center of the target ball 4 is in the same plane as the center positioning rod 2. The center of the arched base 1 is located on the same plumb line, and the level 3 is centrally located on the top surface of the arched base 1 .

[0017] Preferably, the surface of the central positioning rod 2 is provided with a length scale line 21 , and when the central positioning rod 2 is in a free state, its zero scale is tangent to the top surface of the arched base 1 .

[0018] A method for quickly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com