Separation and extraction method of cytisine

A kind of technology of genistein and extraction method, applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The separation and extraction method of a kind of cytisine: take 3Kg of dried and pulverized whole herb of lanceolus chrysanthemum, extract 3 times with methanol with a plastid ratio of 1:5, combine the extracts, concentrate to no alcohol, Viscous, under neutral pH conditions, extract twice with 3Kg chloroform, discard the lower chloroform phase, adjust the upper aqueous phase to pH = 12 with aqueous sodium hydroxide solution, extract 3 times with 3.8kg chloroform , combined the chloroform phase of the lower layer and concentrated to dryness to obtain 33g of cytisine crude product, which was then dissolved in 0.5L ethyl acetate, eluted with ethyl acetate through alumina column chromatography, tracked and monitored by TLC, and the target substance was collected and concentrated To dryness, recrystallize with 0.25L acetone to obtain 25g of pure product with a content of 99%. ,

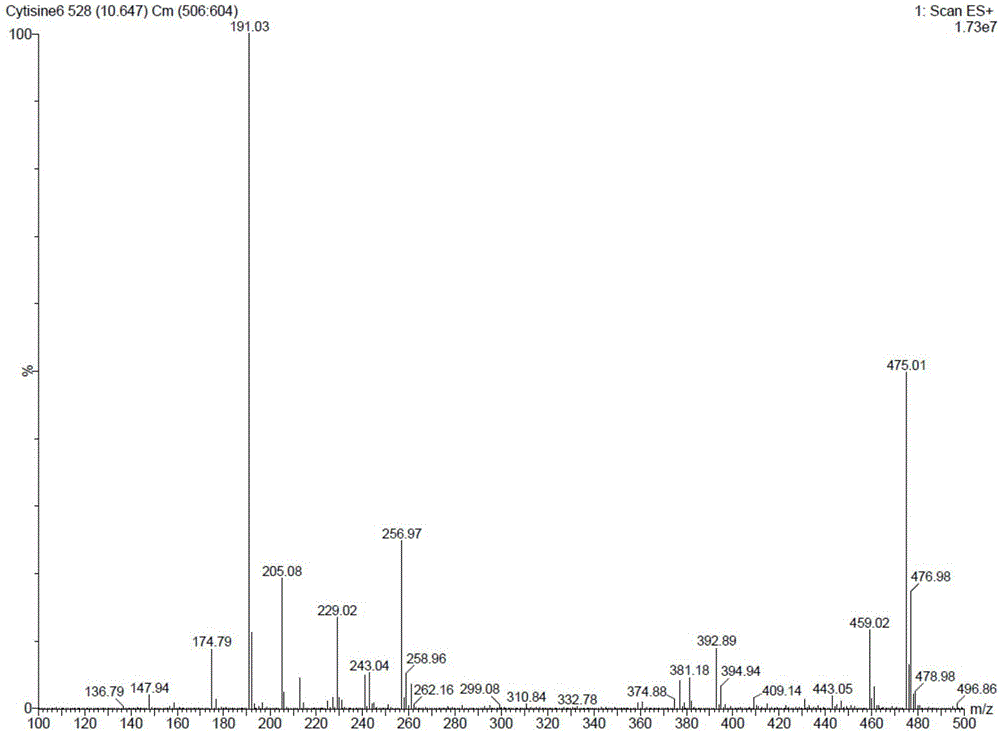

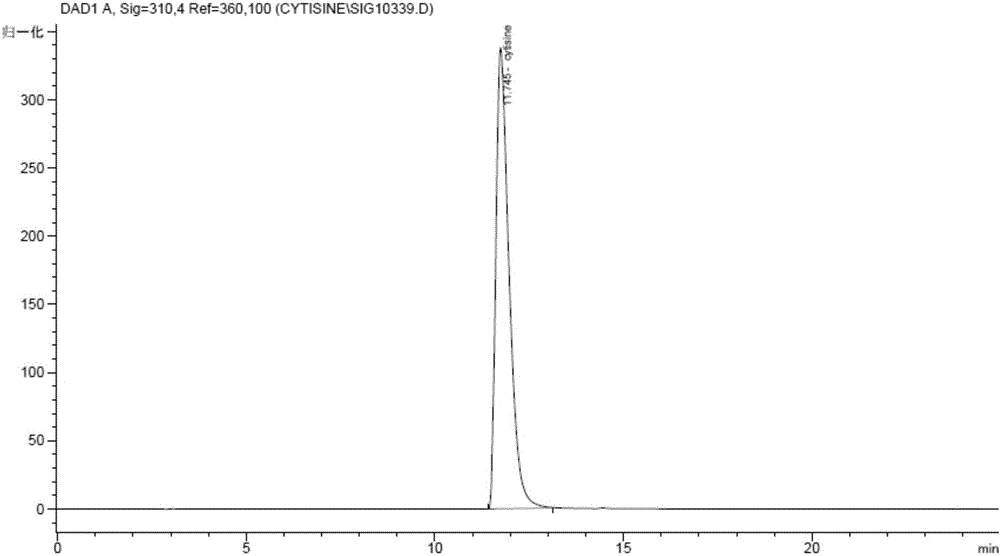

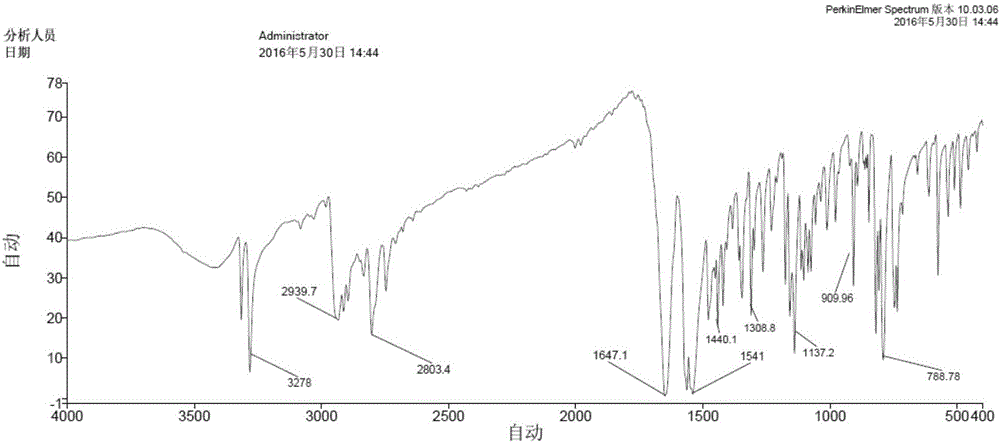

[0015] attached figure 1 It is the schematic diagram of LC-MS of the final pure product of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com