Dynamic tweed with good softness and comfort

A technology of comfort and softness, which is applied in the field of fabrics for high-end clothing, can solve the problems of not being able to meet the needs of multiple directions and having no three-dimensional effect, and achieve the effect of good softness, comfort and strong softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

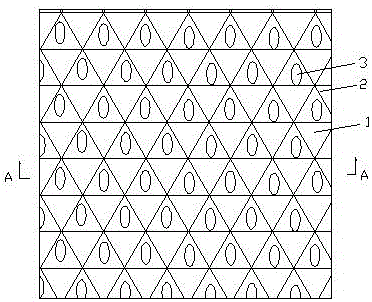

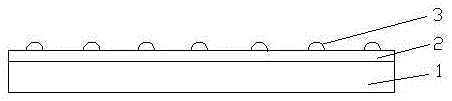

[0014] see figure 1 and figure 2 , the present invention relates to a dynamic tweed with good softness and comfort, including a fabric body 1 . The front side of the fabric body 1 is provided with a filament layer 2 and a decorative ball 3 , and the filament layer 2 and the decorative ball 3 are fixed on the fabric body 1 . The filament layer 2 is full of meshes. The decorative ball 3 is formed by winding filaments, is located in the mesh of the filament layer 2, and protrudes from the plane where the filament layer 2 is located.

[0015] The back of the fabric body is provided with a lining layer, and the lining layer includes: a lining layer body, a PTFE film and a protective film, the PTFE film is arranged on the lining layer body, and the protective film is arranged on the PTFE film The surface is used to protect the PTFE membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com