Mounting and positioning tool and mounting and positioning method for rear oil seal of engine crankshaft

A technology for installation and positioning of the engine, which is applied in the direction of manufacturing tools and hand tools, etc., can solve the problems of large concentricity error between the shaft hole of the rear end plate of the engine and the output gear of the crankshaft, and the inability to locate accurately, so as to reduce the difficulty of positioning and debugging, Save manpower and improve the effect of operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

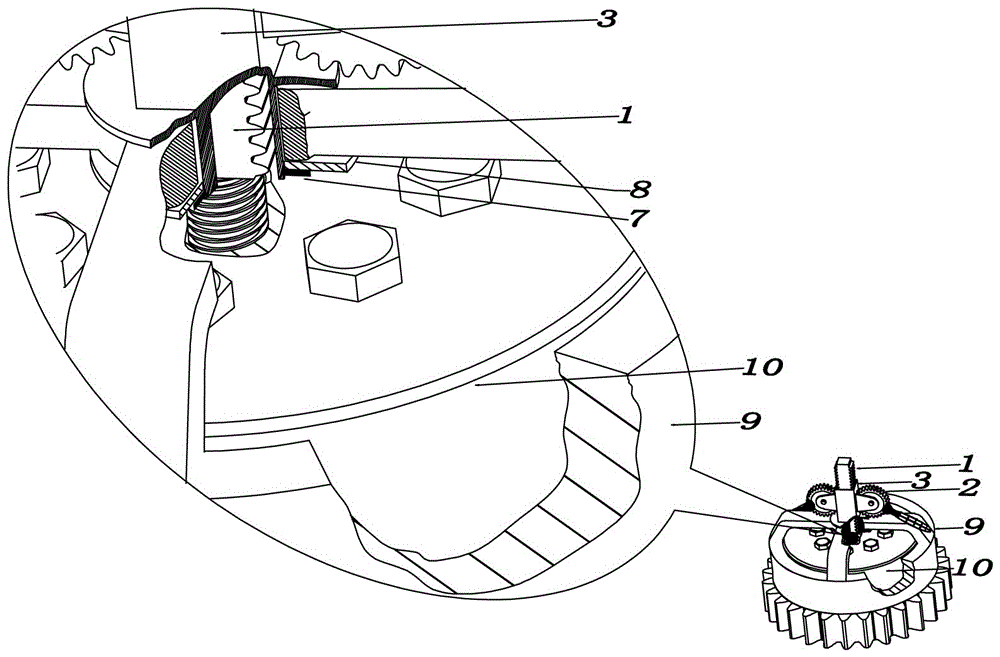

[0024] The specific embodiments of the present invention are further described below with reference to the accompanying drawings.

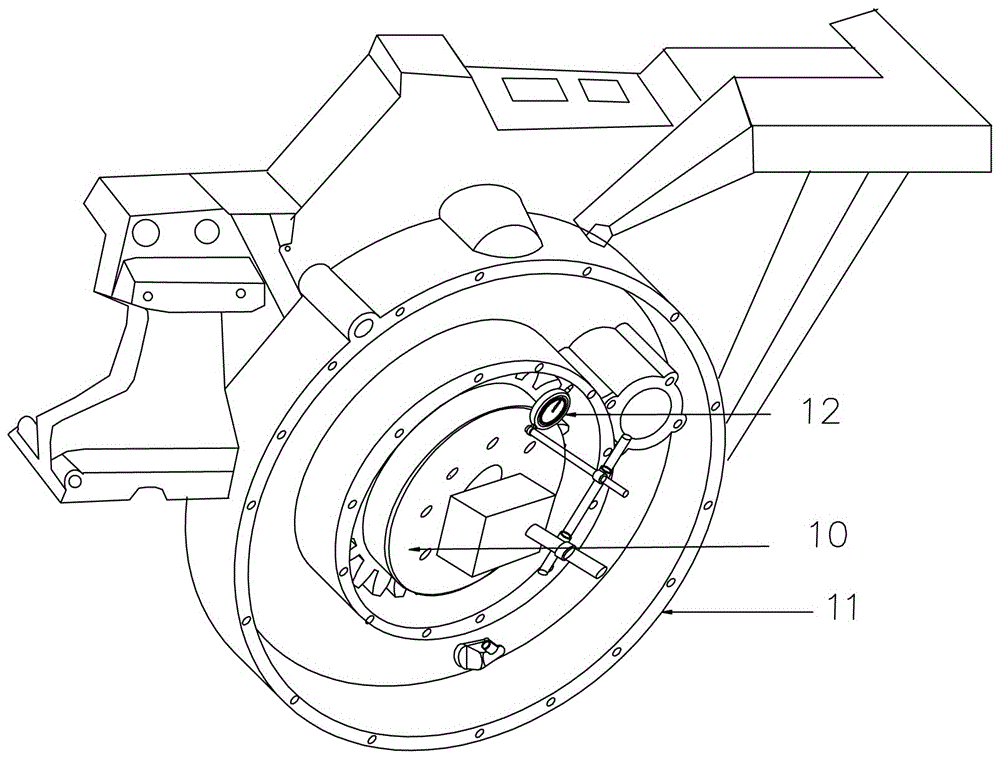

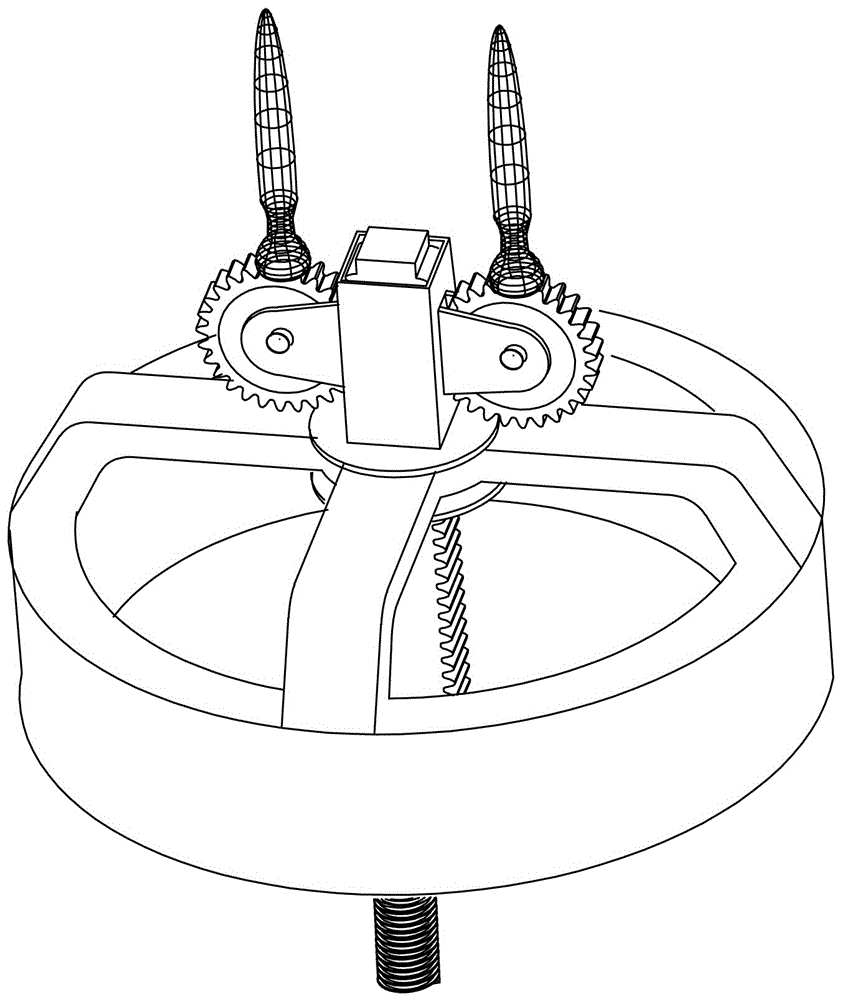

[0025] like figure 1 , 2 , 3 and 4, the engine crankshaft rear oil seal installation and positioning tool of the present invention is characterized in that it comprises a sliding sleeve 3 with a flange at the bottom, and the rectangular holes provided on both sides of the sliding sleeve 3 are provided in each rectangular The push gear support frame at the hole end, the push gear 2 set on each push gear support frame, the push gear rack 1 set in the sliding sleeve 3, the push gear rack 1 set on the sliding sleeve 3 protruding locating sleeve 9 on the edge,

[0026] The pushing rack 1 includes a rack 1-1 at the upper part and a screw 1-2 at the lower part, and each of the pushing gears 2 includes a gear 2-1 and is fixed on the gear 2-1 The handle 2-2, the gears 2-1 on the two push gears 2 respectively pass through the two rectangular holes and en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com