A kind of gravity fine-tuning wire drawing machine and wire drawing process used for wire drawing on the surface of automobile step bars

A technology of surface drawing and drawing machine, which is applied in the direction of machine tools, manufacturing tools, grinding racks, etc., which are suitable for grinding workpiece planes, and can solve the problems of unstable drawing effect, unguaranteed drawing quality, and low efficiency, and achieve guaranteed The effect of reliability and operability, high stability and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

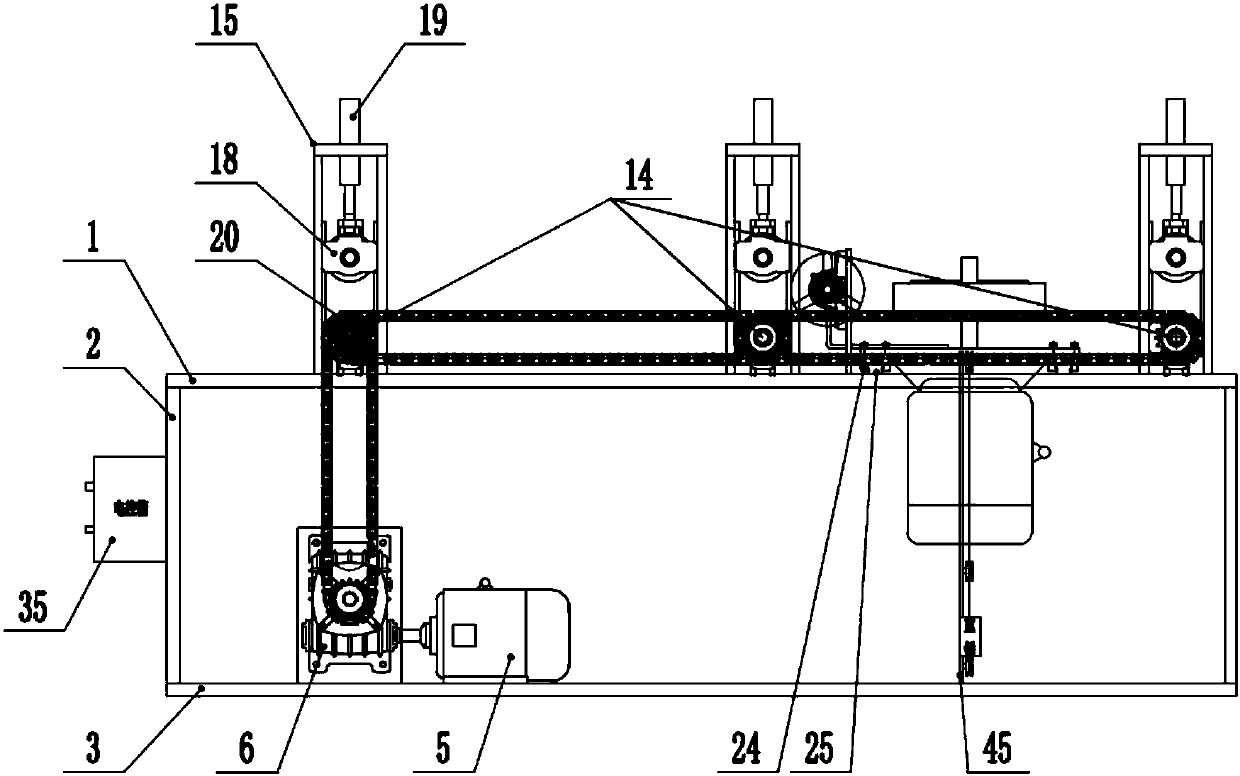

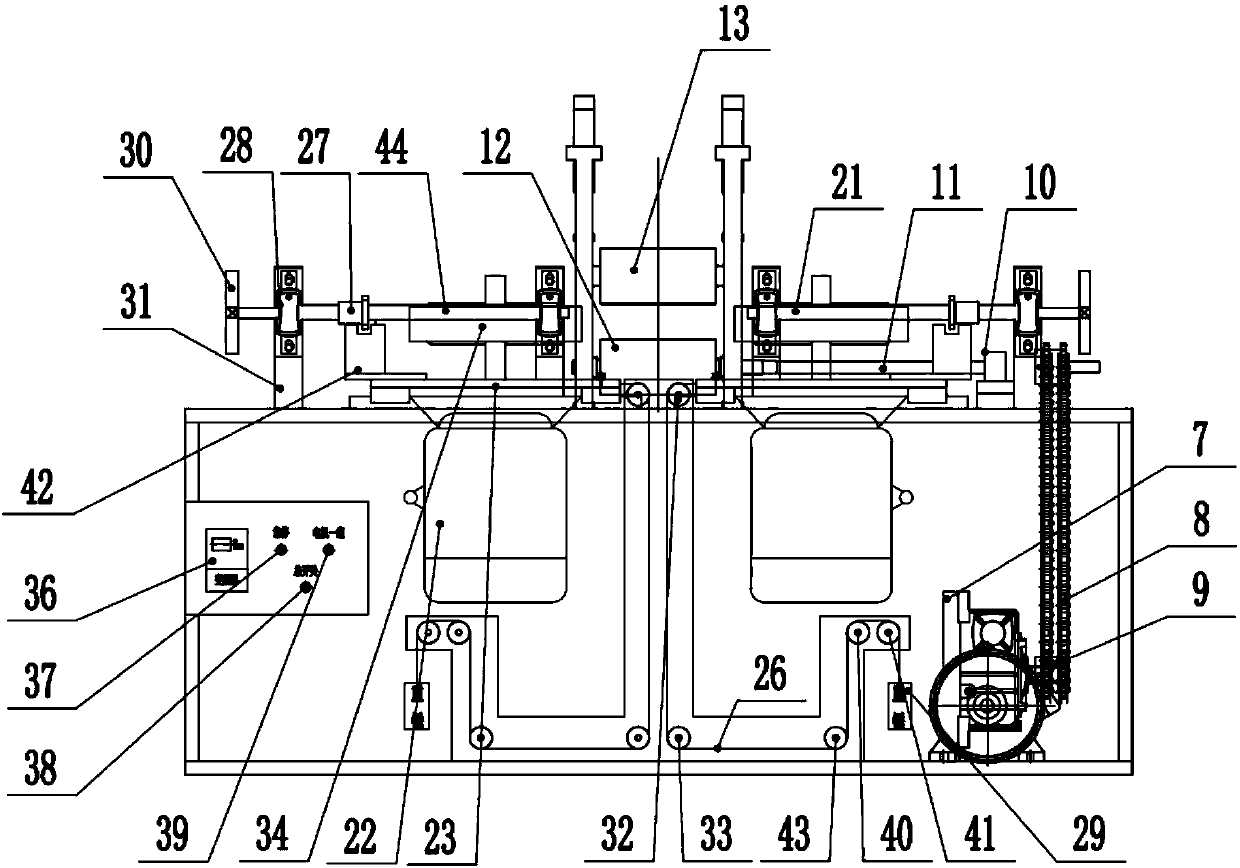

[0024] Such as figure 1 and figure 2 As shown, a gravity fine-tuning wire drawing machine used for drawing the surface of automobile step bars is composed of a worktable, a transmission mechanism, a pneumatic fine-tuning mechanism for wire drawing and a circuit control mechanism. The workbench is composed of an upper workbench 1, a side frame 2 and The lower workbench 3 is composed, the upper workbench 1 is set above the left and right side frames 2, and the lower workbench 3 is set under the left and right side frame 2;

[0025] Described transmission mechanism is made of transmission motor 5, speed reducer 6, speed reducer mounting plate 7, chain 8, speed reducer sprocket 9, bearing block 10, transmission rod 11, driving wheel 12, driven wheel 13, a plurality of sprockets 14, A plurality of gantry frames 15, sliders 18, lead screws 19, fixed blocks 20 and shaft couplings 21 are formed, the transmission motor 5 and the reducer mounting plate 7 are all arranged on the lower ...

Embodiment 2

[0029] Such as figure 1 and figure 2 As shown, a kind of drawing process of the gravity fine-tuning wire drawing machine used for the surface drawing of automobile step bars comprises the following steps:

[0030] (1), first open the main switch 38 in the electric control box, the equipment circuit is connected, the transmission motor 5 starts to work, and the driving wheel 12 is driven by the reducer 6 and the chain 8 to start rotating;

[0031] (2), adjust the knob on the frequency converter 36, and adjust the number on the frequency converter display frequency to 50;

[0032] (3) Adjust the handwheels 30 on both sides simultaneously according to the width dimension required by the wire drawing workpiece, and adjust to the appropriate position of the wire drawing workpiece. In the opened space, the drawing workpiece is placed above the driving wheel 12 of the gantry frame, and the height of the slider 18 is adjusted through the lead screw 19, so that the driven wheel 13 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com