Modular conveyor mat and module therefor, and sprocket wheel and conveyor system

A modular, sprocket technology, applied in the field of conveying pads, which can solve problems such as smaller pad pitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

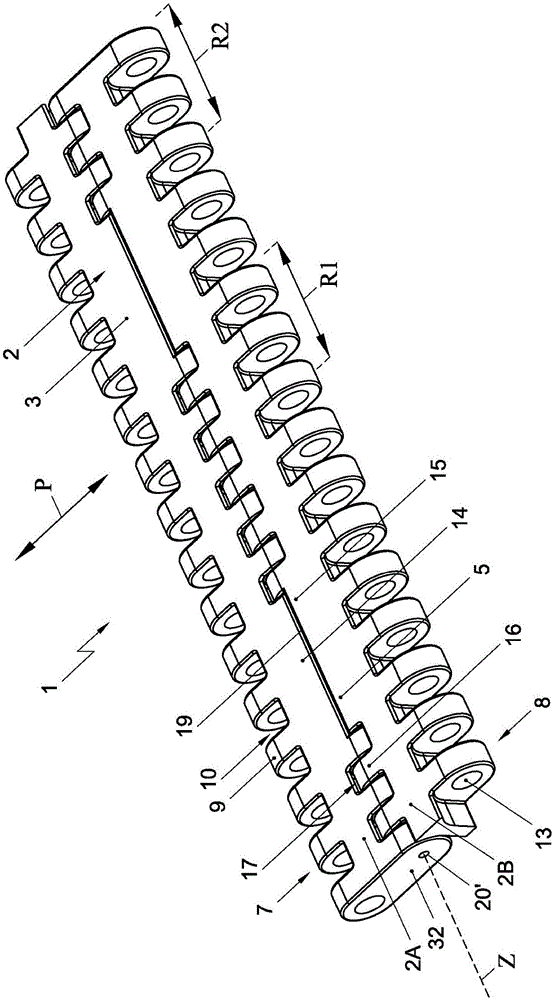

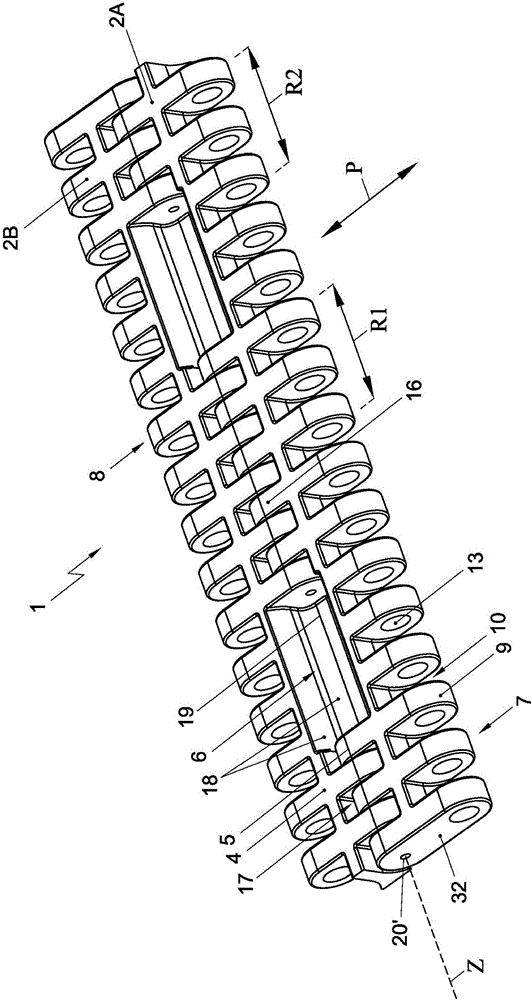

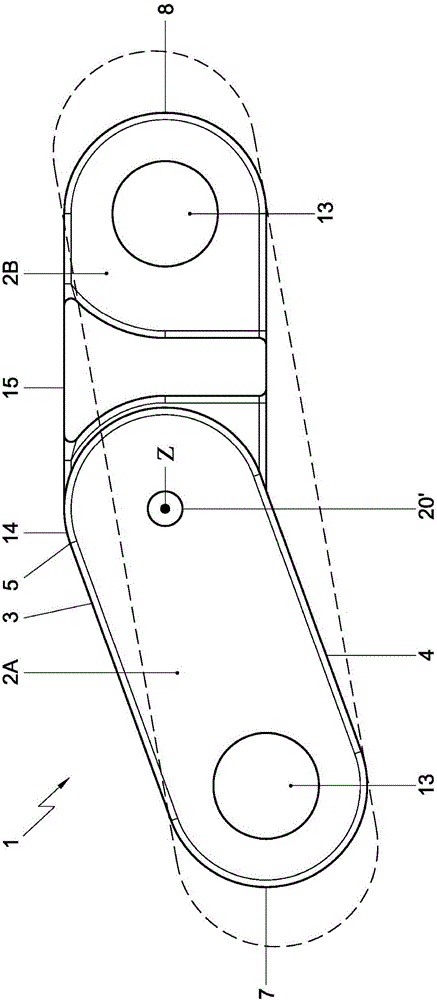

[0031] With reference to the accompanying drawings, specifically Figure 1-3 , shows a module 1 for a modular transfer mat. The pad module 1 comprises a body part 2 extending transversely to the conveying direction marked with a double-headed arrow P, with a top 3 carrying the products to be conveyed and a bottom 4 cooperating with a conveying track not shown. The bottom 4, viewed along the conveying direction P of the module 1, is provided near the middle part 5 with a tooth chamber 6 extending transversely to the conveying direction for receiving the teeth of the sprocket. The body part 2 is provided at the front part 7 and the rear part 8, viewed in the conveying direction, with a succession of hinge parts 9 and receiving spaces 10 alternately transverse to the conveying direction. The hinge parts 9 and the receiving spaces 10 can be interleaved with the receiving spaces and hinge parts of similar modules that follow in the conveying direction P. The successive modules ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com