Optical cable with high side pressure resisting capacity

A technology of anti-side pressure and ability, applied in the direction of light guide, optics, optical components, etc., can solve the problems of poor pressure resistance and easy damage, and achieve the effect of improving service life, prolonging service life and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

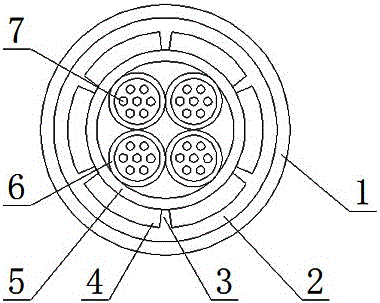

[0018] Such as figure 1 As shown, in this embodiment, an optical cable with strong lateral pressure resistance includes an outer sheath 1, a support sleeve 2 arranged in the outer sheath 1, an inner sheath 5 arranged in the support sleeve 2, a set Several optical fiber sleeves 6 in the inner sheath 5 and several optical fibers 7 arranged in the optical fiber sleeve 6, several protrusions 3 are provided on the inner side of the support sleeve 2, and the inner sheath 5 is supported by the protrusions 3 , by providing protrusions, the inner sheath is supported by the protrusions. When the outer sheath and the support sleeve are twisted, the protrusions can be deflected to reduce the torque transmitted from the inside of the cable to the inner sheath, and can reduce the inner sheath. Wear of the sleeve, thereby improving the torsion resistance and lateral pressure resistance of the optical cable, and prolonging the service life of the optical cable.

[0019] In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com