Double-end-face mechanical seal with H-shaped plugging cavity

A technology of mechanical sealing and cavity sealing, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of increasing the reliability of the oil sealing system, unreliable oil sealing system, and difficult to guarantee safe production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

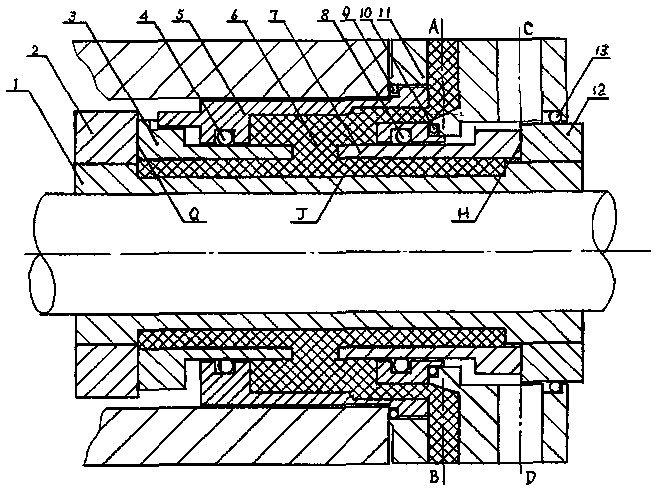

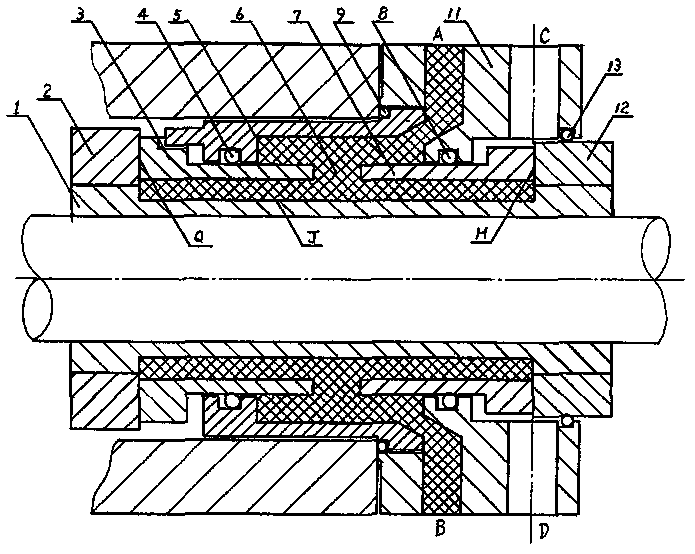

[0033] The specific content of the present invention will be described as necessary according to the drawings in the present invention:

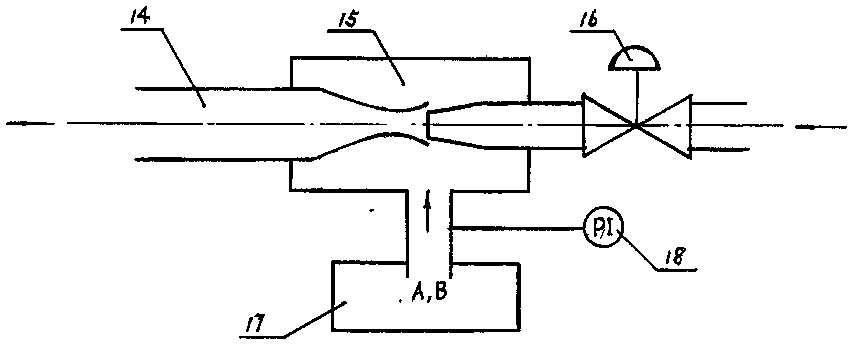

[0034] figure 1 Shown is a schematic diagram of the working principle of the present invention. The grid part of the plugging cavity 6 refers to the mud-like packing filled in the "I"-shaped plugging cavity. In the figure, the front end movable ring structure 2 sleeved on the sleeve 1 The end face of the moving ring and the end face of the front end static ring 3 form a front end sealing surface Q. The front end is in the sealed medium. In the figure, the end face of the moving ring in the rear end moving ring structure 12 sleeved on the sleeve 1 and the rear The end surface of the static end ring 7 constitutes the rear sealing surface H in the external environment, and the mud-like packing tightly wrapped on the annular groove surface of the shaft sleeve 1 constitutes the radial annular sealing surface J, which is installed in the sealing sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com