Connecting method for demountable wooden door

A connection method and technology for wooden doors, which are applied in the directions of windows/doors, building components, buildings, etc., can solve the problems of difficulty in grasping the size of fixing and fastening bolts, looseness, and insufficient fastening of turnbuckles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the following, the present invention will be further explained in conjunction with specific embodiments and accompanying drawings, but the present invention is not limited thereto.

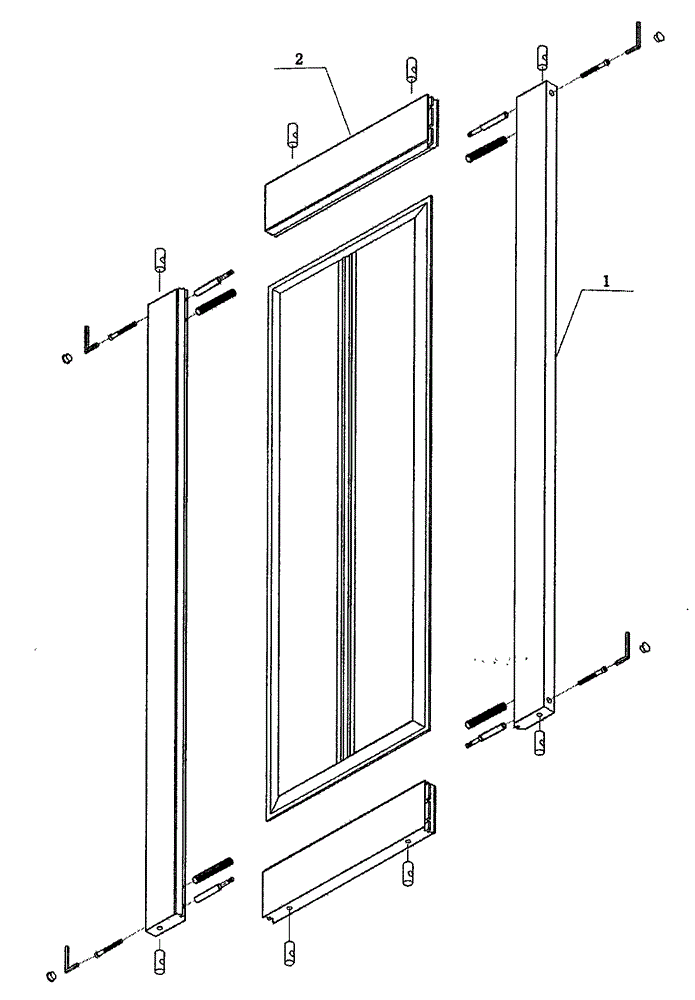

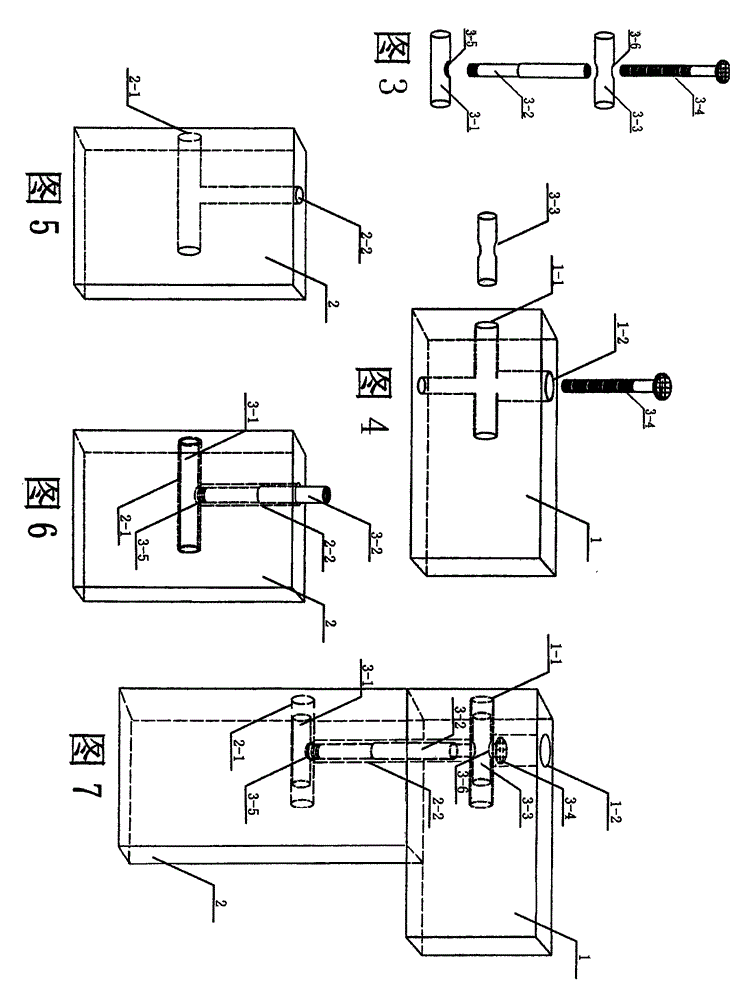

[0016] The detachable wooden door provided by the present invention is as figure 1 Shown door limit (1) and riser (2) its inner connection adopts the connection method of four sections two points. Such as image 3 Shown its connection hardware (3) is divided into nut tup (3-1) and it is shaped on inner thread hole (3-5), male and female stud bolt (3-2), light hole tup (3-3) ) It is shaped on inner light hole (3-6), fastening bolt (3-4) above it. The connection method of the hardware inside the door (1) and the riser (2) is as follows:

[0017] (1) First disassemble and assemble the wooden door according to the traditional method such as Figure 4 Shown: Make a light hole hammer head round hole (1-1) perpendicular to the end of the door side (1), and then make a light hole hammer head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com