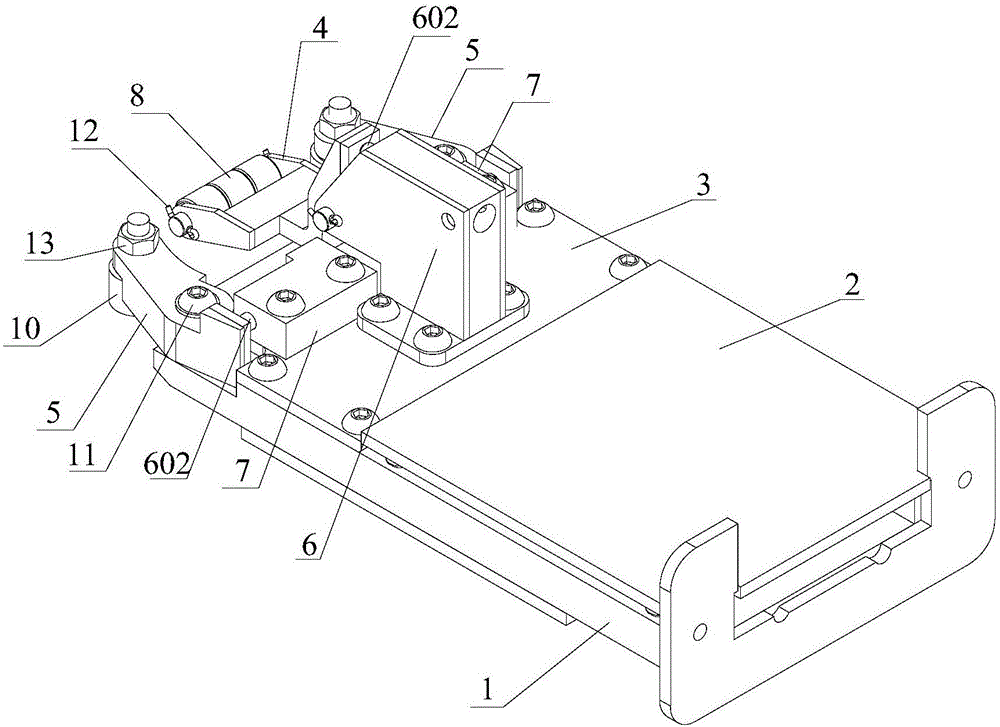

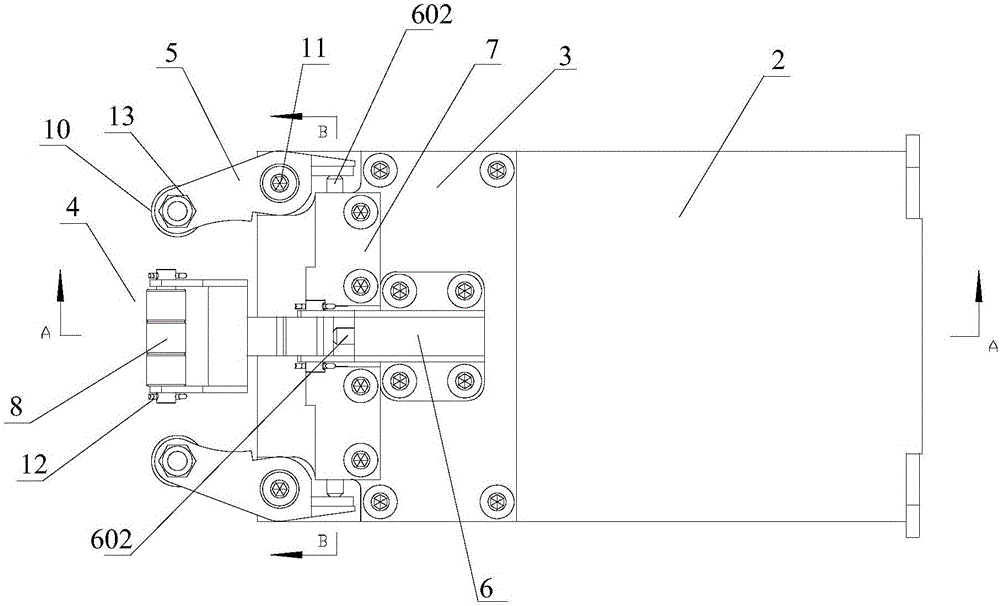

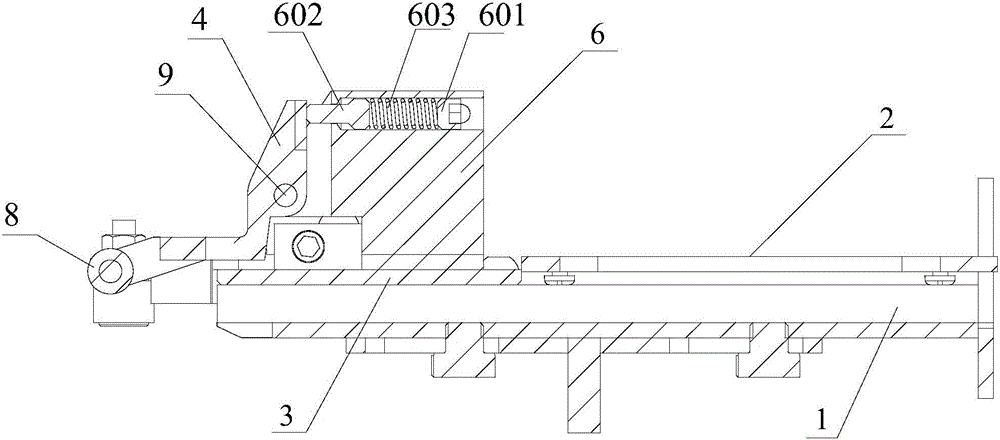

Continuous cap feeding device

A cap feeding and sliding cap technology, which is applied to conveyors, flanged caps, conveyor objects, etc., can solve problems such as affecting efficiency and hindering manual operation, and achieve the effect of improving efficiency, timely and effective reset, and smooth combing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0036] see Figures 5 to 6 The difference between this embodiment and Embodiment 1 is that a stopper 14 for adjusting the swing angle of the front swing arm 4 is provided between the front swing arm 4 and the fixed plate 3, and the stop member 14 runs through the The front swing arm 4 is installed on the fixed plate 3 . The limiting component 14 can be a screw, a screw or a bolt. Adjusting the height of the stopper 14 can adjust the swing angle range of the front swing arm 4 up and down, so that the continuous cap feeding device of the present invention is suitable for conveying bottle caps of different heights, making the application more extensive.

Embodiment 3

[0038] see Figures 7 to 8 The difference between this embodiment and Embodiment 2 is that the cover plate 2 is provided with several hollow grooves 200, and the cover plate 2 is fixed on the sliding cover groove 1 by magnetic adsorption. The periphery of the cover plate 2 is provided with a first adsorption groove 201, the first adsorption groove 201 is provided with a first adsorption body 202, and the sliding cover groove 1 is provided with a corresponding to the first adsorption groove 201 The second adsorption groove 203 , the second adsorption body 204 is arranged in the second adsorption groove 203 , and the first adsorption body 202 is connected to the second adsorption body 204 by magnetic adsorption. Wherein, the first adsorbent 202 and the second adsorbent 204 are both magnets; or the first adsorbent 202 is a magnet, and the second adsorbent 204 is a ferromagnetic metal body; or the first adsorbent 202 is The ferromagnetic metal body, the second adsorption body 204...

Embodiment 4

[0042] see Figure 9 The difference between this embodiment and Embodiment 2 is that the cover plate 2 is provided with several hollow grooves 200, and the cover plate 2 is fixed on the sliding cover groove 1 by magnetic adsorption. The cover plate 2 is a ferromagnetic metal body, and the sliding cover groove 1 is provided with a magnetic adsorption part 100, and the magnetic adsorption part 100 is a magnet. In this embodiment, the cover plate 2 is fixed on the slide cover groove 1 by magnetic adsorption, forming a movable cover plate 2, which can be completely taken out and covered with the cover plate 2, instead of staying in the slide cover groove 1 in the traditional way. Therefore, it will not hinder the operator from adjusting or taking out the bottle cap, and its operability is strong, which can improve the efficiency of specific use.

[0043] In other embodiments, it may also be that the sliding cover groove 1 is a ferromagnetic metal body, and the cover plate 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com