Single-circle-rotation-actuated continuous spray distributor

A technology of actuators and actuating collars, applied in the direction of a single handheld device, spray device, liquid spray device, etc., can solve problems such as feasibility defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

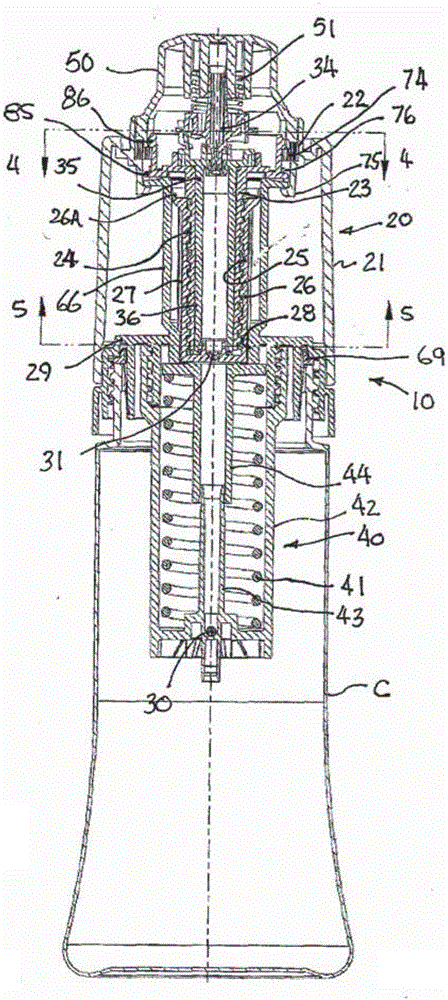

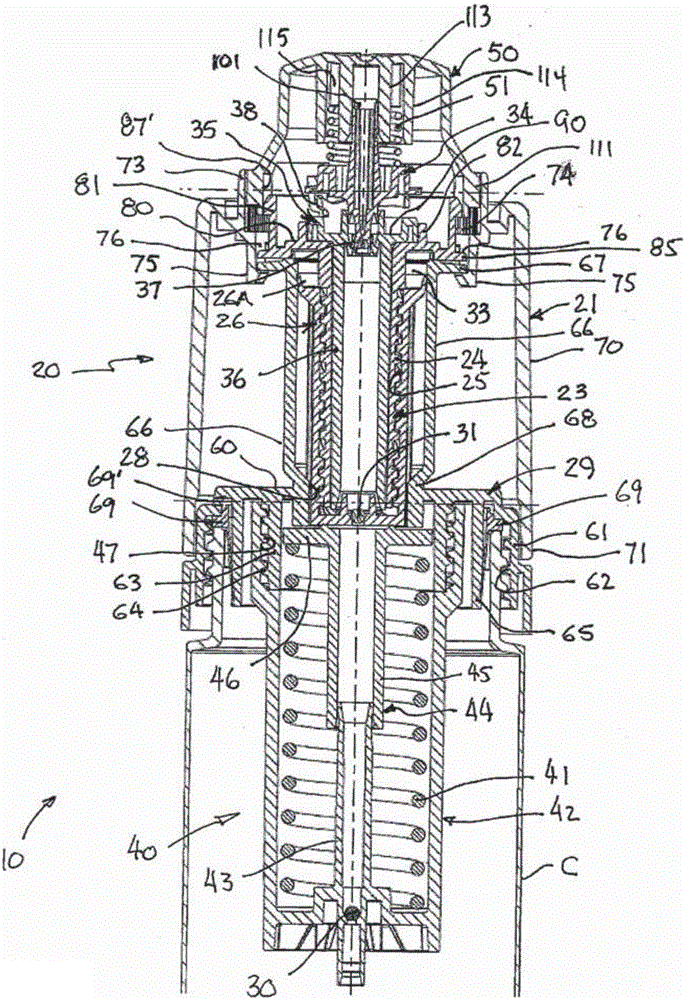

[0090] Figure 1-Figure 18 A first preferred embodiment of the invention is shown. In this form of the invention, an energy storage assembly 10 comprising a pump mechanism 20 and a spring mechanism 40 is mounted to a container C for dispensing product therefrom (not shown).

[0091] Such as Figure 1-Figure 7 , Figure 9A and Figure 9B As clearly shown in , the pump mechanism 20 includes a rotatable actuating collar 21 connected by an escapement 22 to a drive screw 23 having an externally threaded tubular shaft 24 that is connected to a hollow An internal thread 25 in a tubular piston 26 engages, the hollow tubular piston 26 having a sliding seal 26A at its upper end. Axial splines 27 on the outer surface of the piston engage mating axial splines 28 in a bell cylinder 29 mounted at the open upper end of the container C. The splines prevent the piston from rotating, causing the piston to move from image 3 The first non-operating position shown reciprocates to Figure 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com