Fine sand cleaning and recycling mechanism of mudstone regenerating system

A technology of regeneration system and recovery mechanism, which can be used in cleaning methods and utensils, cleaning methods using liquids, solid separation, etc., and can solve problems such as clogging of screen meshes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

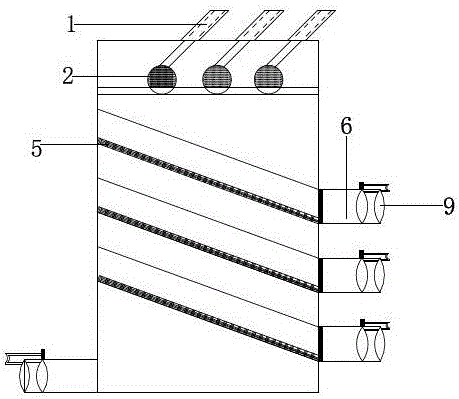

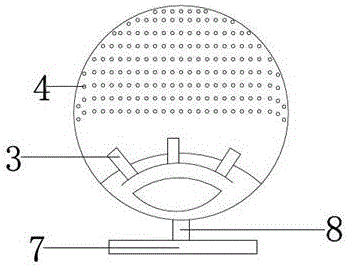

[0031] A fine sand cleaning and recovery mechanism of a mud stone regeneration system, comprising a fine sand feeding device, a fine sand cleaning device and a fine sand sorting device, characterized in that: the fine sand feeding device comprises at least one feeding conveyor belt 1; The conveyor belt 1 is connected with a fine sand cleaning device, the fine sand cleaning device includes a rotating cleaning ball 2, a water spray pipe 3 is arranged inside the cleaning ball 2, and a plurality of small holes 4 are arranged on the outer wall of the cleaning ball 2; The fine sand classification device includes screens 5 with diameters that oscillate from large to small, which are arranged in sequence from top to bottom; each screen 5 can be inclined to one end; connect.

[0032] In the present invention, the cleaning ball 2 with the small holes 4 on the outer wall is arranged, the mud and stone are first put into the cleaning ball 2, and the cleaning ball 2 rotates. Fly out from ...

Embodiment 2

[0034] A fine sand cleaning and recovery mechanism of a mud stone regeneration system, comprising a fine sand feeding device, a fine sand cleaning device and a fine sand sorting device, characterized in that: the fine sand feeding device comprises at least one feeding conveyor belt 1; the feeding The conveyor belt 1 is connected with a fine sand cleaning device, the fine sand cleaning device includes a rotating cleaning ball 2, a water spray pipe 3 is arranged inside the cleaning ball 2, and a plurality of small holes 4 are arranged on the outer wall of the cleaning ball 2; The fine sand classification device includes screens 5 with diameters that oscillate from large to small, which are arranged in sequence from top to bottom; each screen 5 can be inclined to one end; connect.

[0035] The rotational speed of the cleaning ball 2 is 120-180 r / min.

[0036]In the present invention, the cleaning ball 2 with the small holes 4 on the outer wall is arranged, and the mud and stone ...

Embodiment 3

[0039] A fine sand cleaning and recovery mechanism of a mud stone regeneration system, comprising a fine sand feeding device, a fine sand cleaning device and a fine sand sorting device, characterized in that: the fine sand feeding device comprises at least one feeding conveyor belt 1; The conveyor belt 1 is connected with a fine sand cleaning device, the fine sand cleaning device includes a rotating cleaning ball 2, a water spray pipe 3 is arranged inside the cleaning ball 2, and a plurality of small holes 4 are arranged on the outer wall of the cleaning ball 2; The fine sand classification device includes screens 5 with diameters that oscillate from large to small, which are arranged in sequence from top to bottom; each screen 5 can be inclined to one end; connect.

[0040] The inner wall of the cleaning ball 2 includes an air outlet corresponding to the outer wall, which corresponds to the small hole 4 after rotation.

[0041] In the present invention, the cleaning ball 2 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com