A control system for a twister

A control system and whisker twisting machine technology, applied in the field of control, can solve the problems of easy error operation, backward technology, inconvenient maintenance, etc., and achieve the effects of avoiding damage to equipment, high degree of automation, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

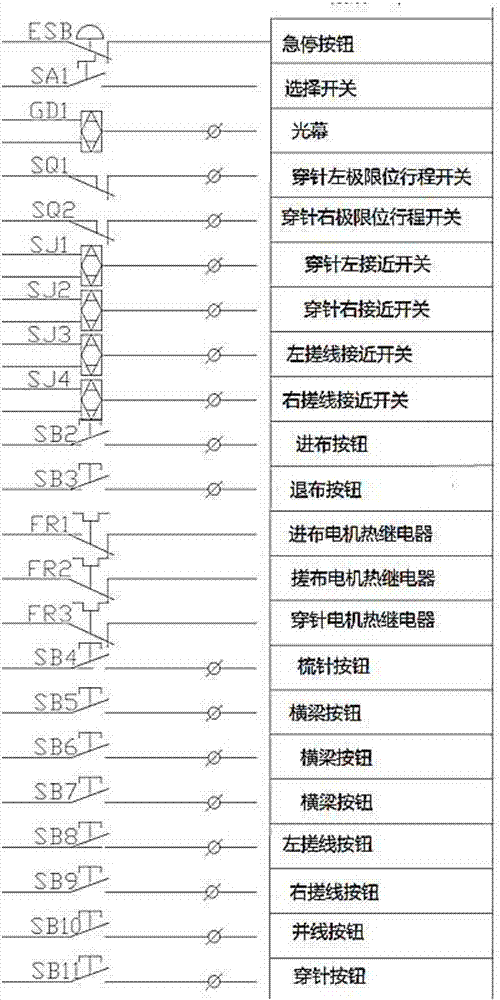

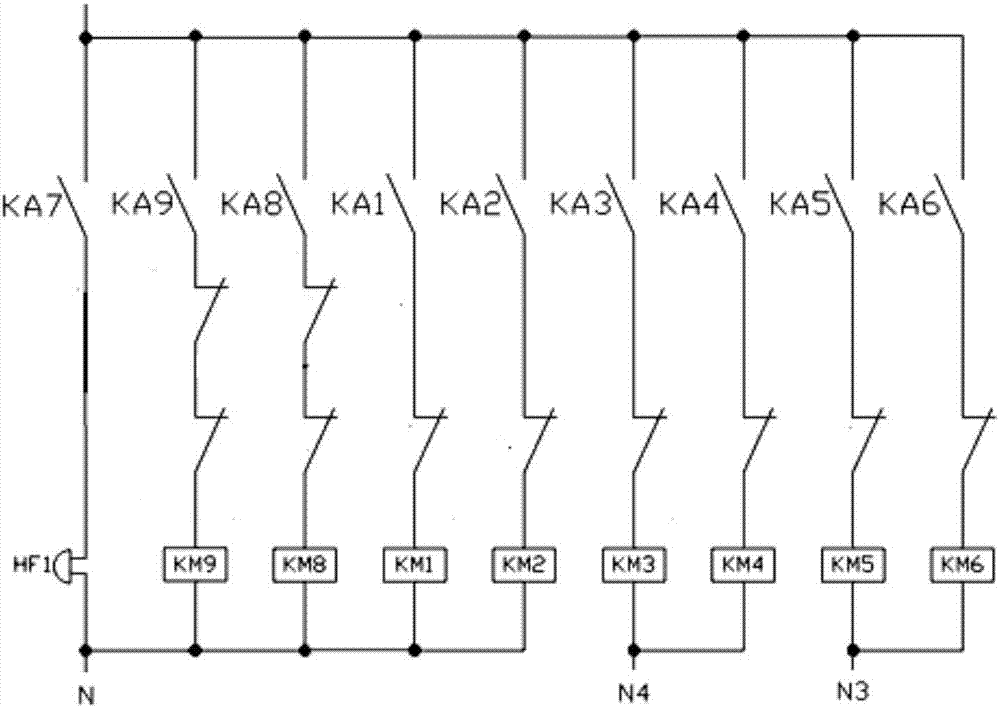

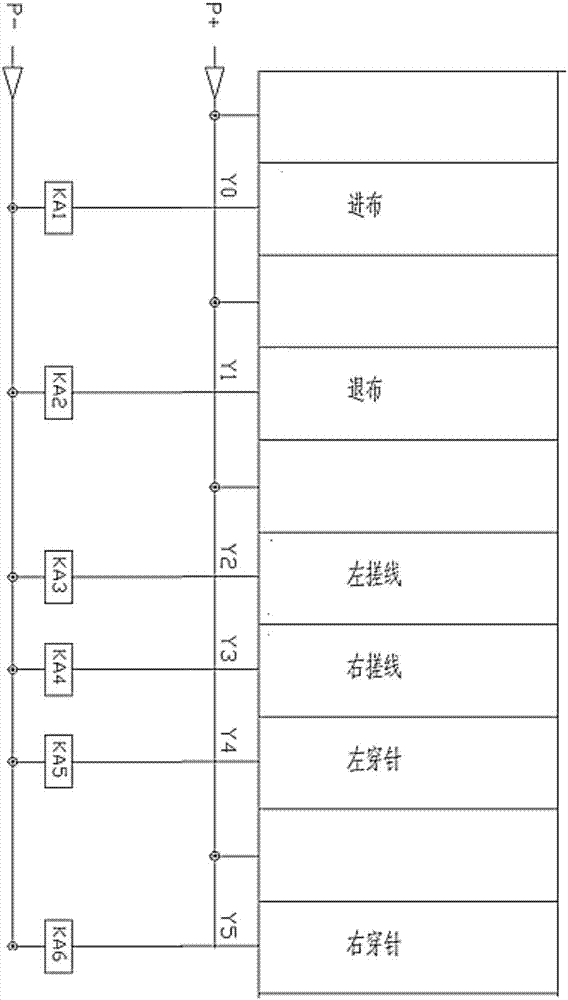

[0029] Such as Figure 1-5 As shown, the present invention discloses a kind of control system of twister, comprising PLC controller, electromagnetic valve, proximity switch, push button switch, AC contactor and relay, PLC controller collects the trigger signal of proximity switch and push button switch respectively, The PLC controller analyzes and judges the trigger signals of the proximity switch and the button switch, and the PLC controller outputs the switching signals to the solenoid valve or the relay according to the results of the analysis and judgment, and the relay controls the pull-in and release of the AC contactor.

[0030] The button switches include cloth feed button, cloth eject button, comb needle button, beam button, thread rubbing button, thread doubling button and needle threading button;

[0031] The cloth feeding button makes the cloth winding motor of the twisting machine rotate forward to feed the cloth through the PLC controller;

[0032] The cloth eje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com