A method for transferring hosiery thread from hosiery needles

A sock needle and sock thread technology, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems that the coil is difficult to detach from the sock needle, the sock thread is difficult to detach from the sock needle, and difficult to transfer successfully.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described below with reference to the drawings, in which like parts are denoted by like reference numerals.

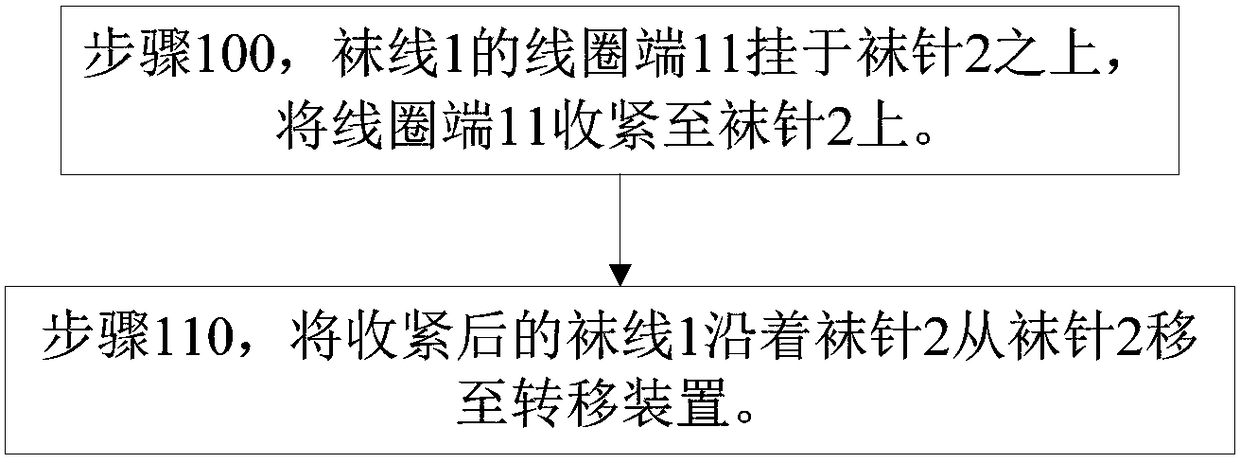

[0021] figure 1 It is a flowchart of an embodiment of the present invention. Among them, in step 100, the coil end 11 of the sock thread 1 is hung on the sock needle 2, and the coil end 11 is tightened onto the sock needle 2; in step 110, the tightened sock thread 1 is drawn from the sock needle 2 along the sock needle 2; Needle 2 moves to the transfer device.

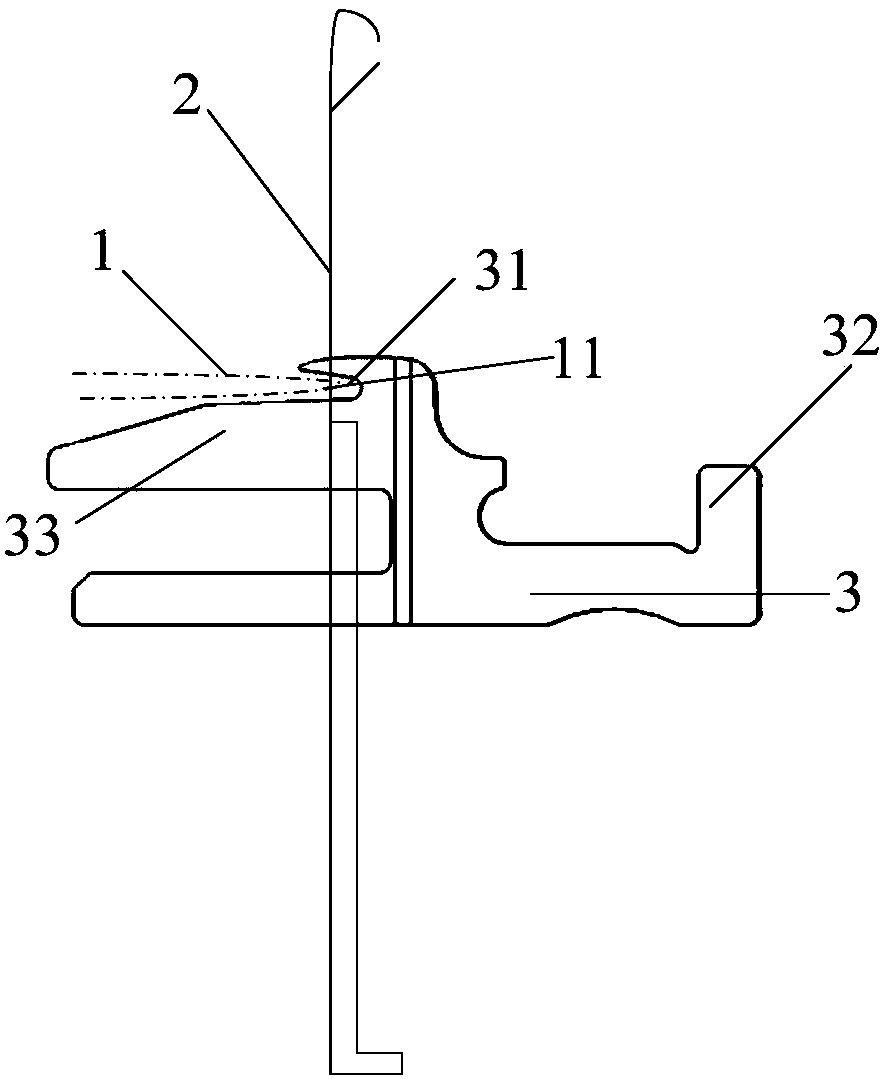

[0022] In one embodiment, step 100 is implemented through step 101, such as Figure 2-3 As shown, in step 101, a green sheet 3 is placed outside the sock needle 2, and the loop end 11 of the sock thread 1 is squeezed with the green sheet 3 to tighten the loop end 11 onto the sock needle 2. figure 2 The coil end 11 of the middle sock thread 1 is far away from the sock needle 2. At this time, the raw gram 3 is placed near the coil end 11, and the coil end 11 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com