Installation device and installation method for automobile radiator sealing strip

A technology for automobile radiators and installation devices, which is applied to vehicle components, transportation and packaging, and metal processing, etc. It can solve the problems of easy error in water chamber buckling and uneven laying of sealing strips, so as to ensure the pass rate of pressure test and improve Compactness and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

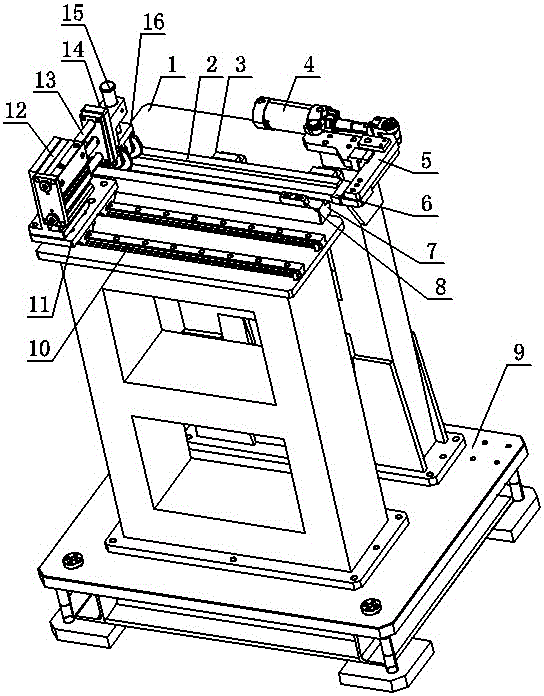

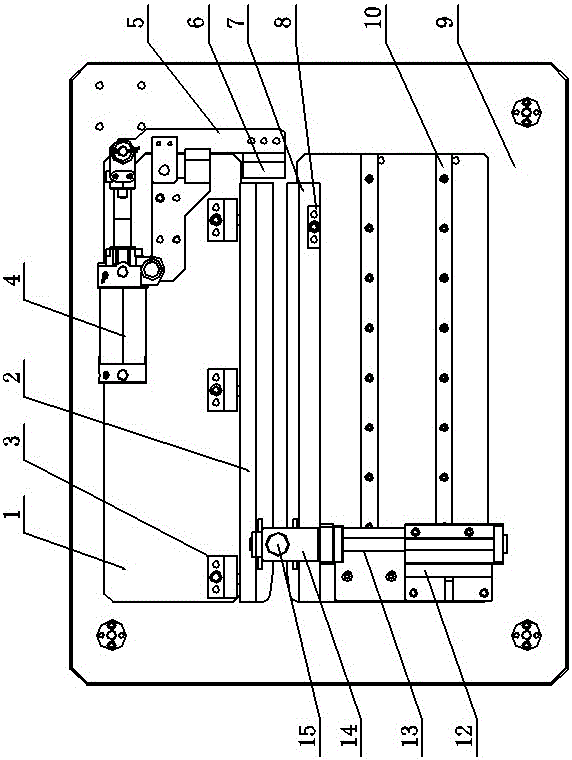

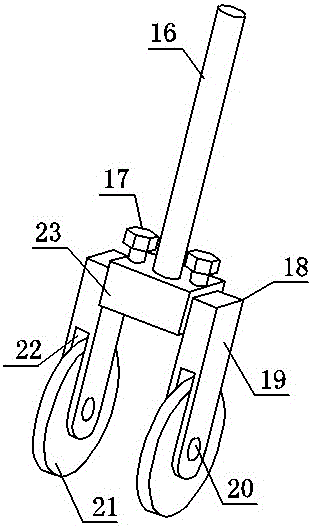

[0040] The installation device of the automobile radiator sealing strip of the present invention comprises a frame 9, two guide rails, a sealing strip flattening roller device 16, a propulsion device and a control panel, and the flat plate on the frame 9 comprises a front flat plate and a rear flat plate which are relatively arranged front and back. Plate 1, the two guide rails are the front guide rail 7 and the rear guide rail 2, the front guide rail 7 is fixed on the front plate, the front guide rail 7 is provided with a convex spacer 8, and the rear guide rail 2 is fixed on the rear plate through multiple adjustment mechanisms 3 1, each adjusting mechanism 3 includes an L-shaped fixing seat and an adjusting bolt, and each L-shaped fixing seat is fixed on the rear plate 1, and a plurality of L-shaped fixing seats are arranged in a row along the axis of the guide rail, and each adjusting The bolts all pass through the L-shaped fixing seat and the rear guide rail 2 sequentially...

Embodiment 2

[0050] The installation method of the automobile radiator sealing strip is to use the automobile radiator sealing strip installation device in Embodiment 1, and the steps are:

[0051] (1) Adjust the distance between the two guide rails and the distance between the two rollers 21 in the sealing strip flattening roller device 16;

[0052] (2), press the limit switch, and fix the limit block 6 on one end of the two guide rails;

[0053] (3) Place the radiator main piece between the front rail 7 and the rear rail 2;

[0054] (4) Lay the sealing strip in the main fin groove of the radiator;

[0055] (5) Press the propulsion switch 26 to push the two rollers 21 to the corresponding position between the two guide rails through the propulsion device;

[0056] (6) Push the handle 15 to make the two rollers 21 roll on the sealing strip;

[0057] (7) Press the reset switch 27, and move the two rollers 21 away from the guide rail and return to their original positions through the prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com