A device for dismantling a pressure-holding box

A technology of pressure-holding boxes and buckle blocks, which is applied in the field of fixtures and fixtures, can solve problems affecting production capacity, achieve the effects of improving production efficiency and production capacity, being convenient to use, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

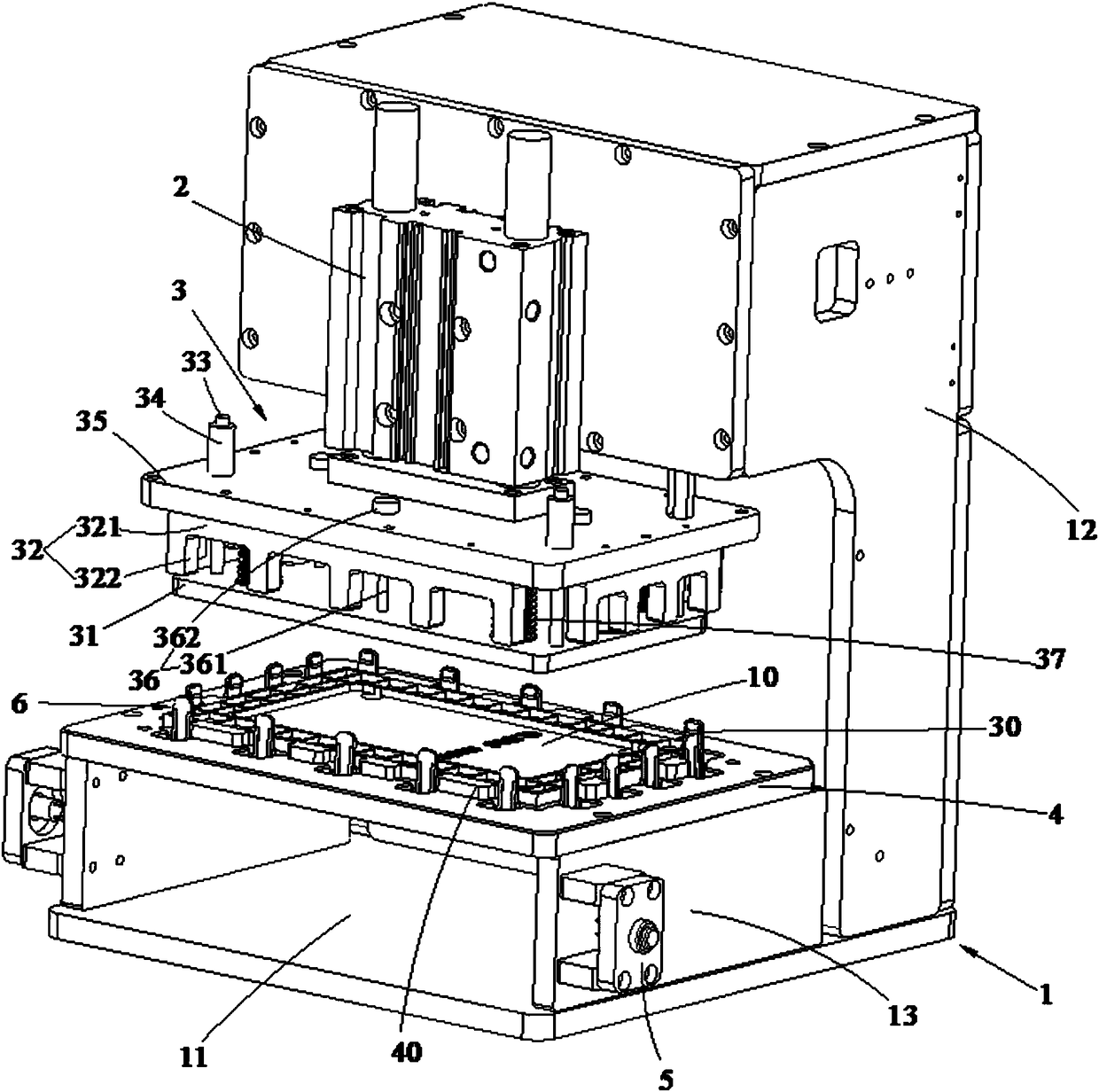

[0026] The present invention will be further described below based on the drawings.

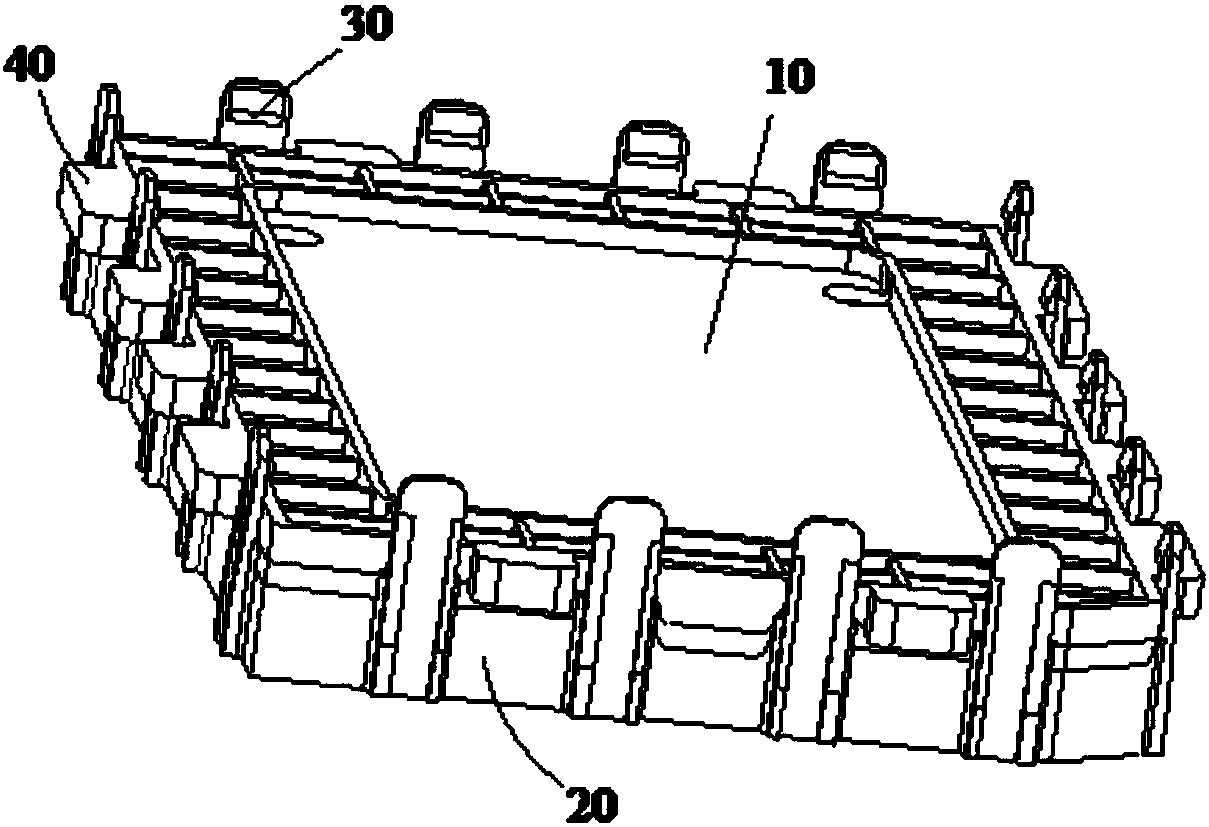

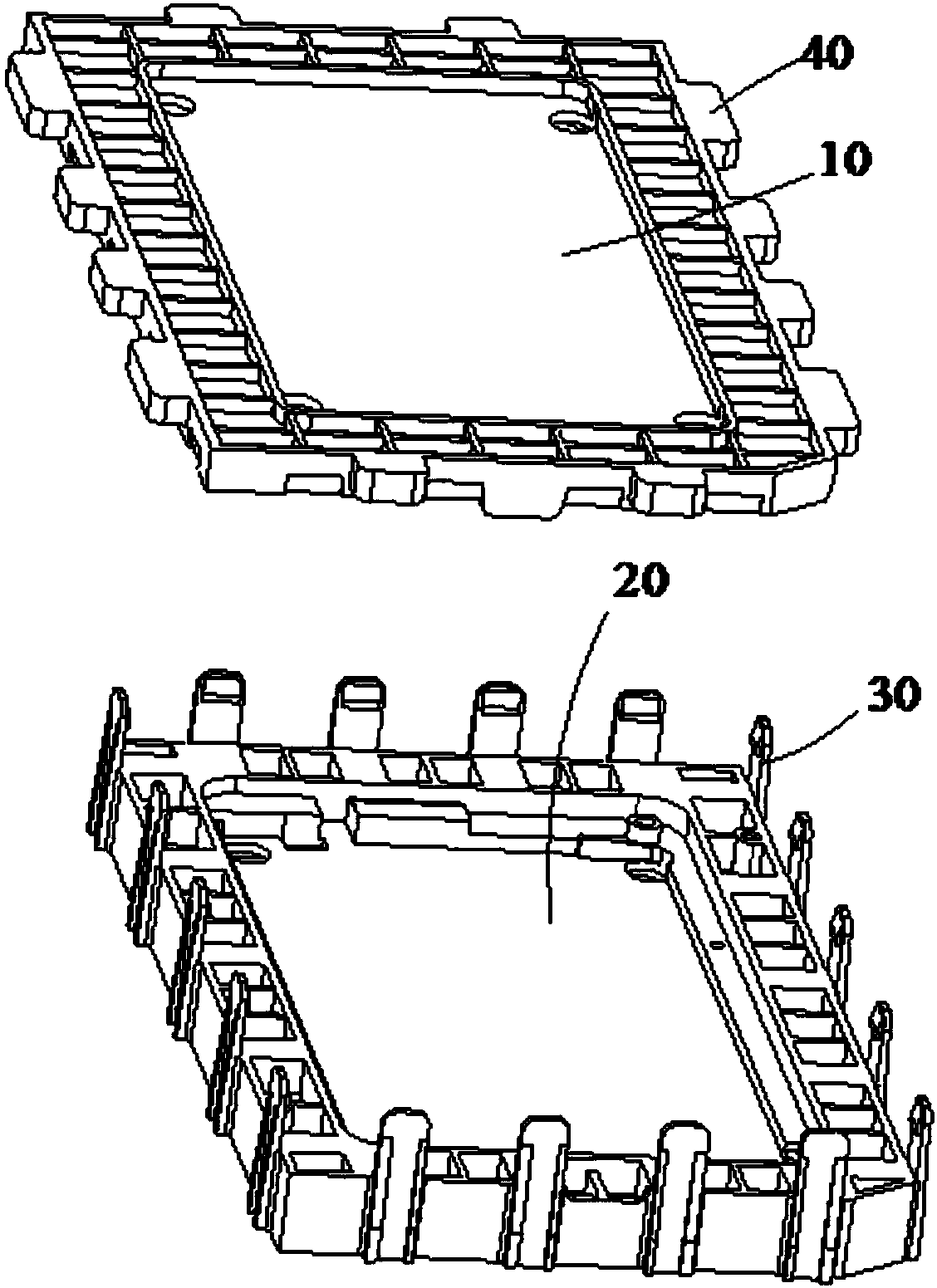

[0027] Such as Figure 3 to Figure 6 As shown, the present invention provides a device for disassembling the pressure holding box 6, including a frame 1 and a driving mechanism 2, a pressing mechanism 3, a fixing mechanism 4, and a starting mechanism 5 respectively arranged on the frame 1. The starting mechanism 5 Connected to the driving mechanism 2, the driving mechanism 2 is located above the pressing mechanism 3 and can control the up and down movement of the pressing mechanism 3, and the fixing mechanism 4 is located below the pressing mechanism 3;

[0028] The press-down mechanism 3 includes a support plate 31 used to open the buckle 30 fixed on the pressure holding box 6 of the fixing mechanism 4 and a pressing buckle block 32 used to press down the buckle 30 on the pressure holding box 6 . After the buckle 30 is opened, it is easier to press it down to better realize separation.

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com