Minimum power distribution area-based distributed feeder automation device arrangement method

A technology for feeder automation and power distribution area, applied in circuit devices, electrical components, information technology support systems, etc., to achieve the effect of simple device design, practical and reliable device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

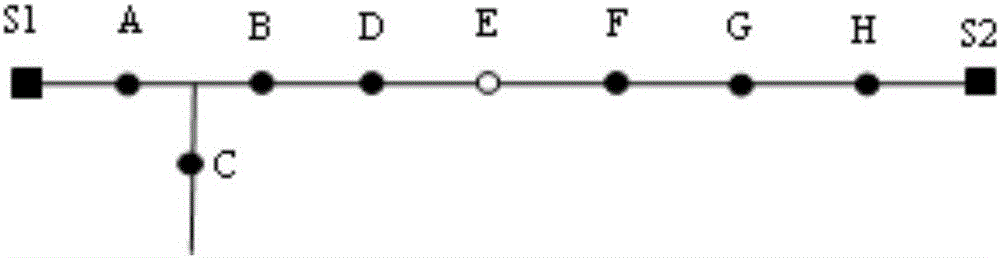

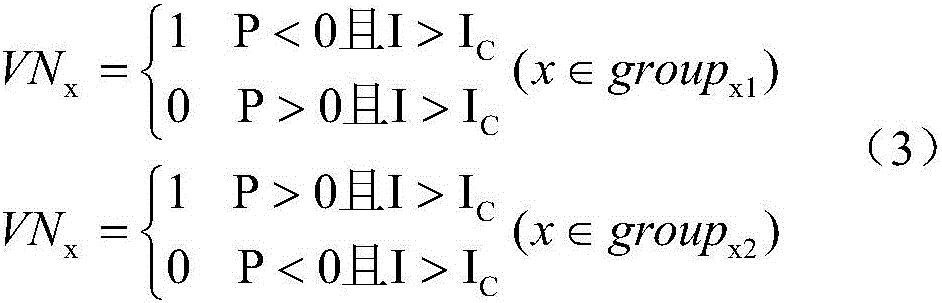

[0072] Such as figure 1 In the distribution network shown, when the system is running in open loop, if a fault occurs in the BD section of the switch, the action steps of each distributed feeder automation device are as follows:

[0073] The feeder automation device at the switch S1 in the smallest power distribution area can know that the fault current flows through the acquisition unit, and the direction of active power is from the switch to the area S1A, so VN S1 = 1, through the communication unit, it can be known that switch A in the adjacent minimum power distribution area experiences fault current, and the direction of active power is to flow out of area S1A, so VN S11 =0, it can be seen from the formula (2) in the calculation unit that Vgroup S11 ={1&&0}=0, so A S1 =0, switch S1 does not act. Do not start the control unit.

[0074] From the sampling unit of the feeder automation device at switch A in the minimum power distribution area adjacent to switch S1, it can...

Embodiment 2

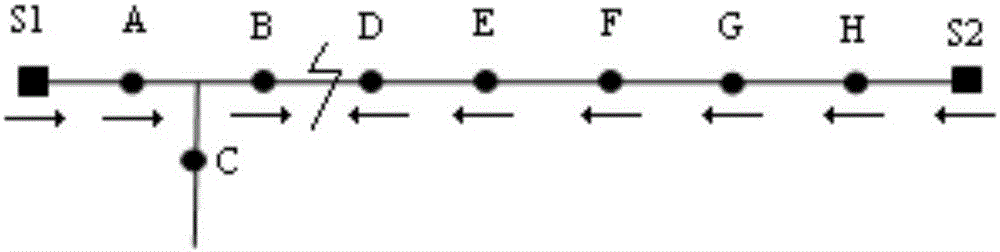

[0081] When the system operates in closed loop, forfigure 1 In the distribution network shown, if a fault occurs in the switch BD section, switches S1, A, B, D, E, F, G, H, and S2 all experience a fault current, and switch C does not experience a fault current. The fault active power flow direction is as follows: figure 2 As shown, the action steps of each distributed feeder automation device are:

[0082] The analysis of switches S1, A, and C is exactly the same as that of the open-loop operation, and will not be repeated here.

[0083] From the sampling unit of the feeder automation device at switch B, it can be known that it has experienced a fault current. It can be seen from the communication unit and calculation unit at switch B that for the first adjacent switch group ABC at switch B, the logic value of switch A is 1, the logic value of switch B is 0, and the logic value of switch C is 1. Logical value Vgroup of an adjacent group B1 is 0; for the second adjacent swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com