Thread steel production line speed self-adaption automatic counting device

An automatic counting and production line technology, applied in the direction of counting mechanisms/items, instruments, etc., to achieve the effect of eliminating continuous jitter on the rising edge and continuous jitter on the falling edge, and reducing counting errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

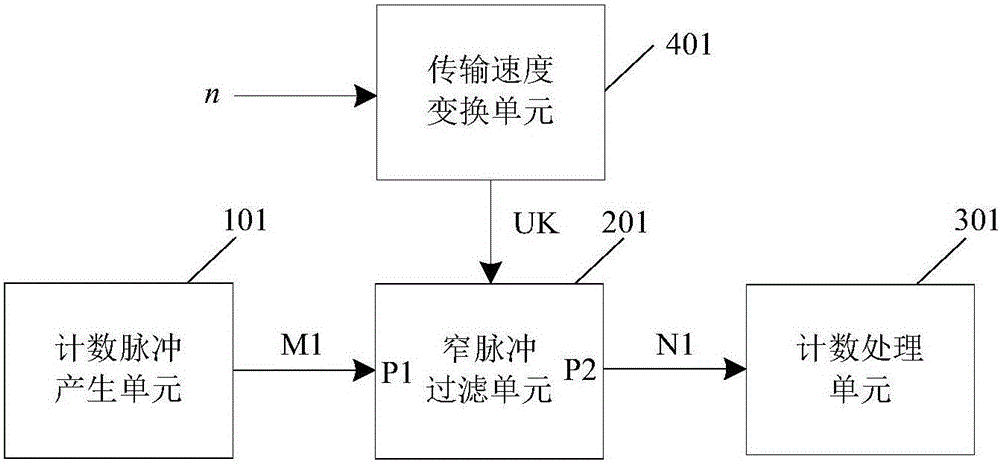

[0025] Such as figure 1 Shown is a structural block diagram of an embodiment of a speed-adaptive automatic counting device for a threaded steel production line. The counting pulse generating unit 101 outputs an initial pulse M1, and the narrow pulse filtering unit 201 performs narrow pulse filtering on M1 to obtain the counting pulse N1 after filtering out the interference pulse. The counting pulse N1 is sent to the counting processing unit 301, and the counting processing unit 301 counts N1.

[0026] The counting pulse generation unit is a photoelectric switch, Hall switch, magnetic reed switch commonly used in the production line, or a counting detection device such as an inductive proximity switch or a capacitive proximity switch. Output an initial pulse signal when a bar passes through the rebar production line. The initial pulse is the count pulse without filtering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com