QT-based cross-platform PLC board level tool testing system and testing method thereof

A test system and test method technology, applied in the field of PLC detection, can solve the problems of single test function, low versatility, low test accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

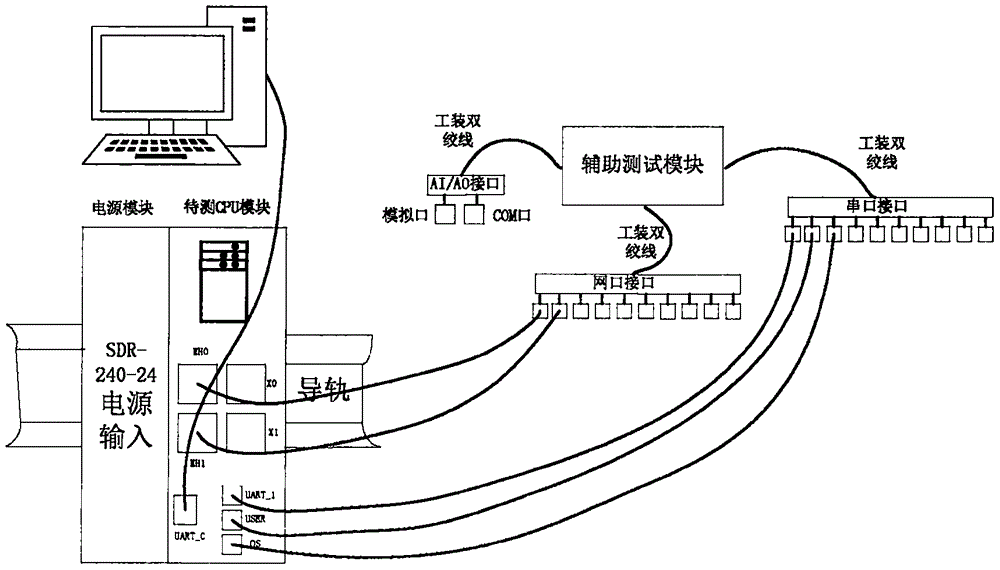

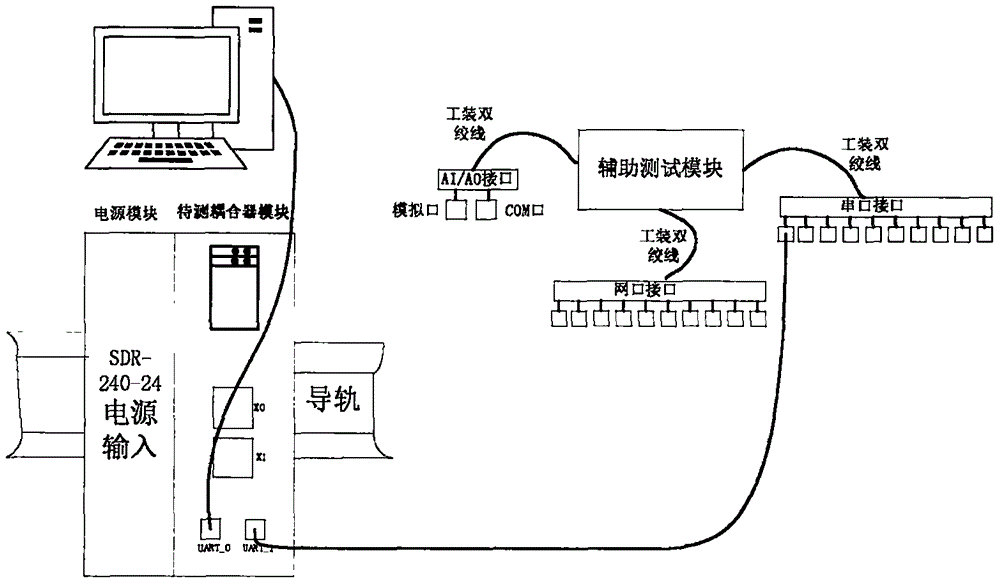

[0108] Such as figure 1 Shown, specify that the present invention provides a kind of cross-platform PLC board-level tooling test system based on QT, including cross-platform board-level tooling test software based on QT, power supply module, PLC single board module to be tested and auxiliary test module, described The PC installed by the QT-based cross-platform board-level tooling test software is connected to the module to be tested through a serial port line, and communicates with the test program of the lower computer of the module to be tested. The power module is connected to the module to be tested to provide power for the board-level tooling test , the module to be tested includes: a CPU module, a coupler module, a digital input module, a digital output module, an analog input module, and an analog output module, which are connected to the auxiliary test module by a serial line, a network cable, and an analog line. The CPU module is interconnected with the IO system thr...

Embodiment 2

[0110] Such as Figures 2 to 13 As shown, the present invention also provides the test method of the cross-platform PLC board-level tooling test system based on QT, and the test method includes the CPU module detection step:

[0111] Step 1. Connect one end of the tooling cable to the UART_0 interface of the CPU module, and the other end to the host computer. After the test system is connected, open the board-level tooling test software.exe program from the host computer, select the CPU module test item, and inspect the CPU module. , the test items include serial port test, network port test, SDRAM test, FLASH test, LED lamp test, DIP switch test, RTC clock test, power-down protection time estimation, COMX test and MAC_EEPROM test, the serial port test includes 3 Item, the test items are UART_1, USER, OS three channel tests, the network port test includes 2 items, the test items are two channel tests of ETH0 and ETH1;

[0112] Step 2, the inspection method of the three channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com