Ultralow-expansion glass ceramic continuous production line and method

A technology of glass-ceramic and production line, which is applied in glass production, glass furnace equipment, glass manufacturing equipment, etc. It can solve the problems of low production efficiency and difficult control of product quality stability, so as to achieve improved production efficiency, controllable product quality, The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

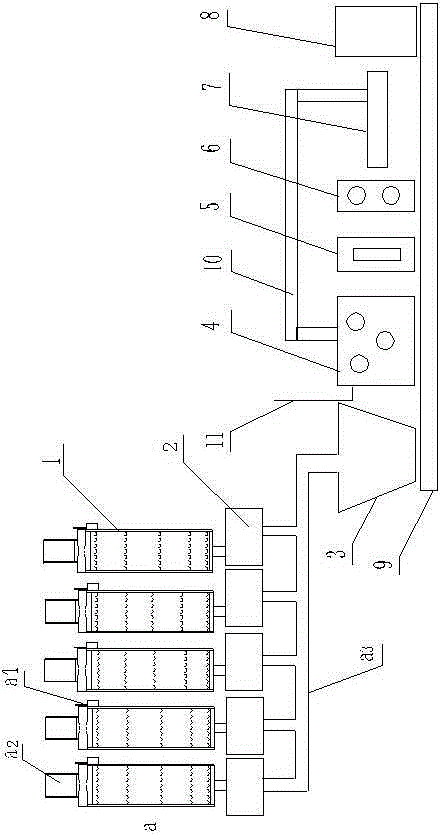

[0019] The continuous production line of ultra-low expansion glass-ceramics includes a raw material matching system a, which includes several raw material conveyors a1; the raw material conveyor a1 is composed of a raw material conveyor belt a2, an electric screen Measuring device 2, the raw material conveyor belt a1 is connected to the electric sieve 1, and the electric sieve 1 is connected to the ingredient weighing device 2.

[0020] Each raw material enters the mixing conveyor belt a2 after the batching and weighing device 2, and the mixing conveyor belt a2 is connected with the mixer 3, and the discharge port of the mixer 3 is connected with the delivery track device 9; One side of the device 9 is sequentially provided with a melting furnace 4 , a molding machine 5 , an annealing furnace 6 , a sorting device 7 , and a crystallization furnace 8 ; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com