Device capable of applying waste heat of ship driving

A technology for ships and drive shafts, which is applied in the directions of ship auxiliary drives, ship propulsion, circuit devices, etc., and can solve problems such as efficiency loss, control valve pressure loss, and ship power grid frequency fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

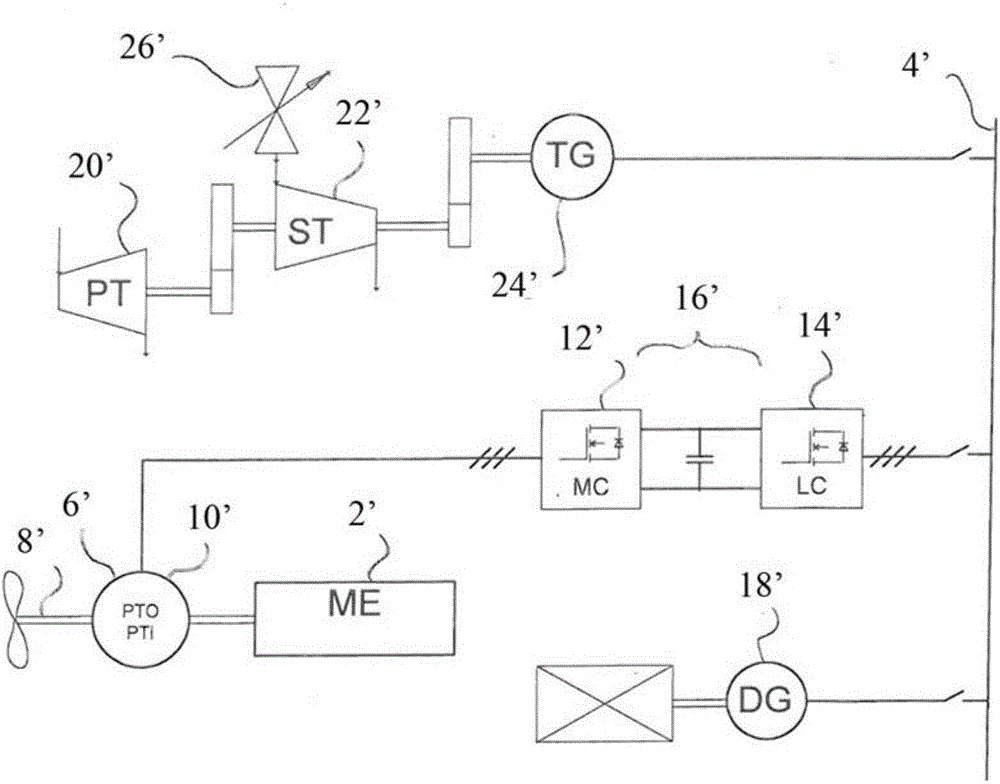

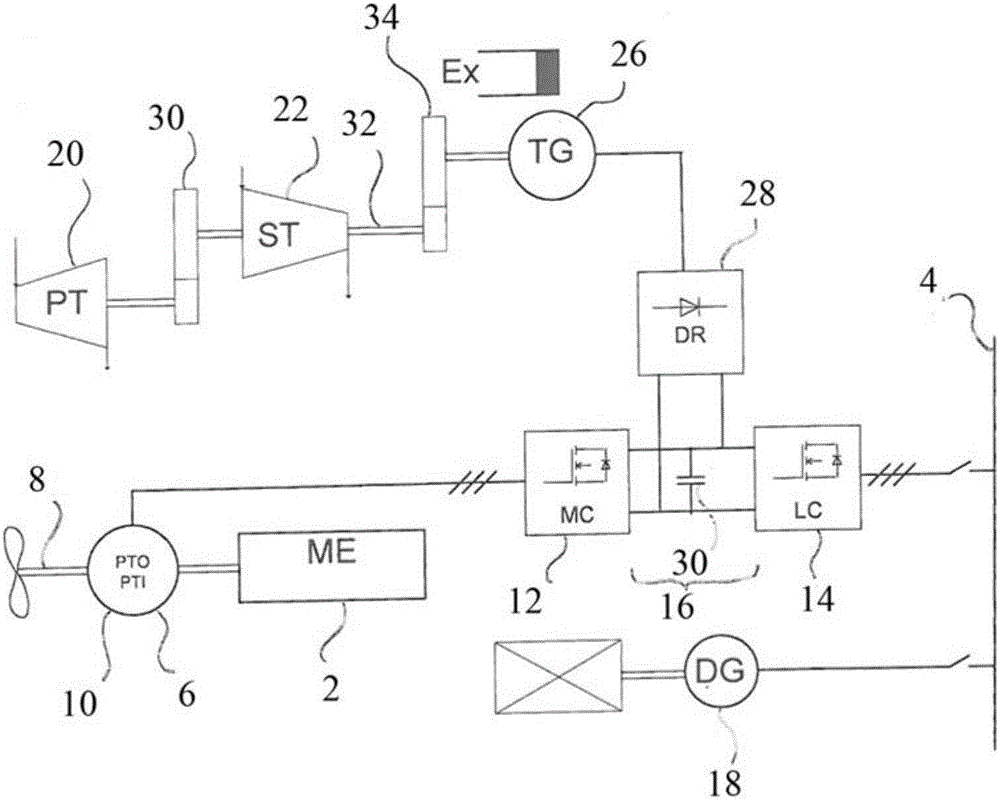

[0023] Modern diesel engines2 for ship propulsion, such as figure 1 and 2 As shown in , has an efficiency of about 50%.

[0024] About 25% of the primary energy will be lost as waste heat. This part of energy waste heat utilization has been realized since more than ten years ago, such as figure 1 shown. Thus in the ship drive, the energy used to supply the ship's grid 4' is used, or the shaft can also be additionally driven by the auxiliary engine 6', the so-called booster engine.

[0025] Thus, a conventional arrangement for propulsion of a ship comprises a diesel engine 2' (the so-called main engine of the ship) which is connected in rotation to the ship's drive shaft 8' and to a generator 10'. The generator is connected to the ship grid through the motor converter 12' and the ship grid converter 14', a DC voltage intermediate circuit 16' is arranged between the motor converter and the ship grid converter, and the generator 10' Supplying energy to the ship's grid 4', or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com