Installation structure of a disc-type electric cabinet for a low-floor vehicle

A technology of installation structure and electrical cabinet, which is applied in the direction of locomotives, etc., can solve the problems of difficult equipment maintenance, no installation points, small upper operating space, etc., and achieve the effects of convenient equipment maintenance, good vibration resistance, and reduced self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

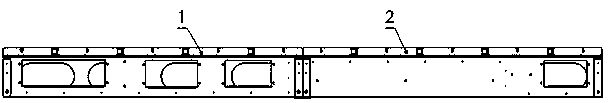

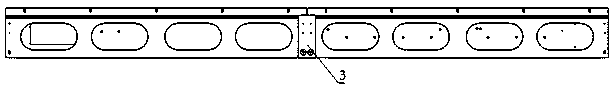

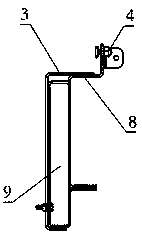

[0029] Such as Figure 1 to Figure 6 The installation structure of a disc-type electrical cabinet for a low-floor vehicle is shown. The main frame is spliced by a plurality of closed tubular cavity structures in the axial direction through the splicing plate 3. After splicing, a long and narrow window spanning the window area of the car body is formed. Type tubular cavity structure; the upper part of the narrow and long tubular cavity structure is provided with a bending part, the bending part is connected to the roof of the vehicle through T-shaped bolt fasteners, and the lower part is connected to the column of the vehicle body through a bracket ; The narrow and long tubular cavity structure is provided with a concave structure for fitting the car body structure; the bending part of the upper part of the narrow and long tubular cavity structure, the lower parts of both ends and the lower part of the splicing plate are all equipped with electrical The installation interfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com