Automatic advancing type bamboo chopstick shear gauge

A technology of traveling and sizing machine, which is applied in the direction of engine components, engine lubrication, mechanical equipment, etc. It can solve the problems of unsatisfactory cutting effect of sawing parts, easy wear of rotating shaft and support beam, and easy splashing into parts, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings:

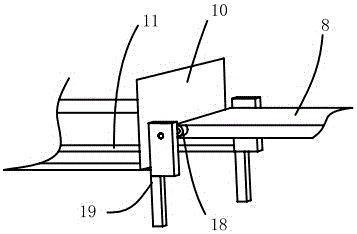

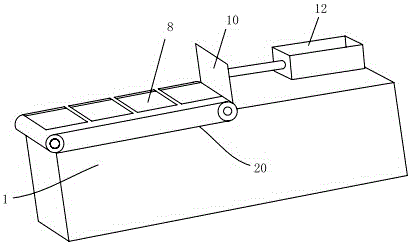

[0019] refer to Figure 1-4 As shown, an automatic advancing bamboo chopsticks sizing machine includes a machine base 1, several sawing units and a feeding device for sawing raw materials located on the machine base 1, and the machine base 1 is also provided with a The dust removal device for the dust discharged after the operation of the sawing unit, the dust removal device includes a dust collection box 2, a dust suction channel and a dust baffle 7 fixed on the machine base 1, the sawing unit includes a support 3, connected to the support The support beam 5 of the seat 3, the rotating shaft 4 and the sawing part 6 connected with the rotating shaft 4, the sawing unit is slidably connected to the machine base 1, and the action of cutting raw bamboo filaments can be performed back and forth, and the feeding device is arranged on the sawing unit The discharge plate 8 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com