Welding Fixtures for Electrolyzer Cathode Steel Rods and Explosive Blocks

A technology for welding fixtures and cathode steel rods, which is applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of complex operation and low welding efficiency, achieve simple device structure, improve welding efficiency, and good welding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

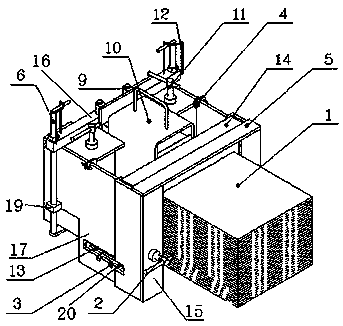

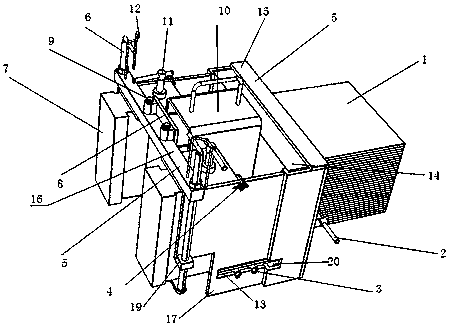

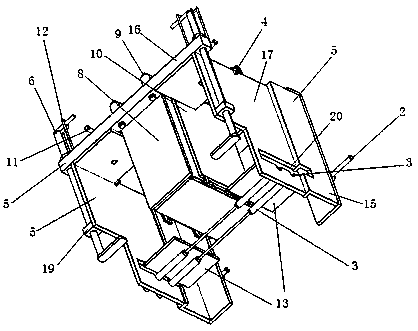

[0027] Embodiments of the present invention: a kind of welding fixture for electrolyzer cathode steel rod and explosion block of the present invention, such as figure 1 – image 3 As shown, the welding fixture includes a fixed frame 5, the fixed frame 5 includes a door-shaped front frame 15 at the front and side panels 17 on both sides. The cross beam 16, the upper part is two cover plates 21 connected with the cross beam 16 and the side plate 17, the width between the side plates 17 is smaller than the width of the door-shaped front frame 15, and the side plate 17 and the door-shaped front frame 15 form a groove shape, just can Connect the explosion block 14 with the busbar 1, and install the explosion block 14 into the door-shaped front frame 15 from the bottom; the welded steel sheet box 8 is fixed in the gap between the two horizontal pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com