Noise prevention multi-grain-size screening crusher

A multi-particle size, anti-noise technology, used in solid separation, separation of solids from solids by air flow, grain processing, etc. Avoid coal accumulation and over crushing, reduce noise pollution, and have the effect of large expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

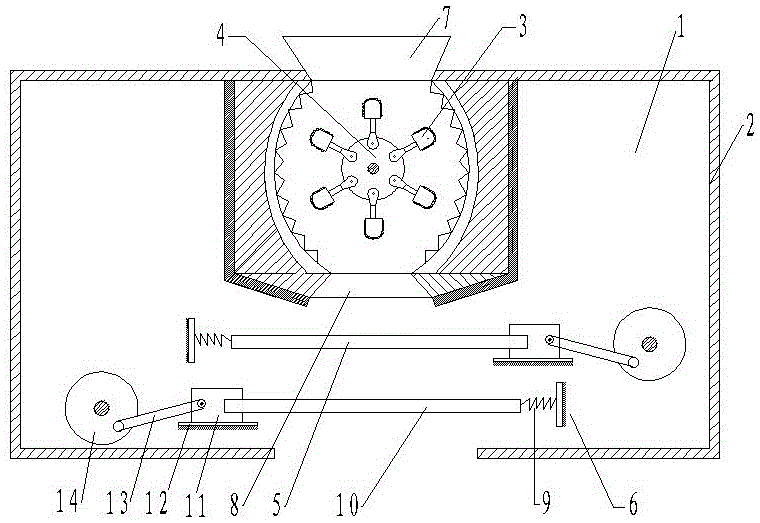

[0009] Such as figure 1 As shown, a noise-proof multi-particle size screening crusher, which includes a crushing box 1, sound insulation cotton 2, a breaking hammer 3, a rotating shaft 4, a primary screening device 5, a secondary screening device 6, and the top of the crushing box 1 A feed port 7 is provided, a discharge port 8 is provided below, a rotating shaft 4 is installed in the middle of the crushing box 1, and at least 3 breaking hammers 3 are installed on the rotating shaft 4, and a layer of soundproof cotton 2 is wrapped outside the crushing box 1, A primary screening device 5 is installed below the discharge port 8 of the crushing box 1 , and a secondary screening device 6 is installed below the primary screening device 5 . The first-stage screening device 5 and the secondary screening device 6 have the same structure, and are all composed of a return extension spring 9, a screening plate 10, a guide block 11, a track 12, a connecting rod 13 and an eccentric wheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com