Device for forming a ball of yarn and weighing yarn

A yarn and weighing machine technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of prone to errors, high production costs, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

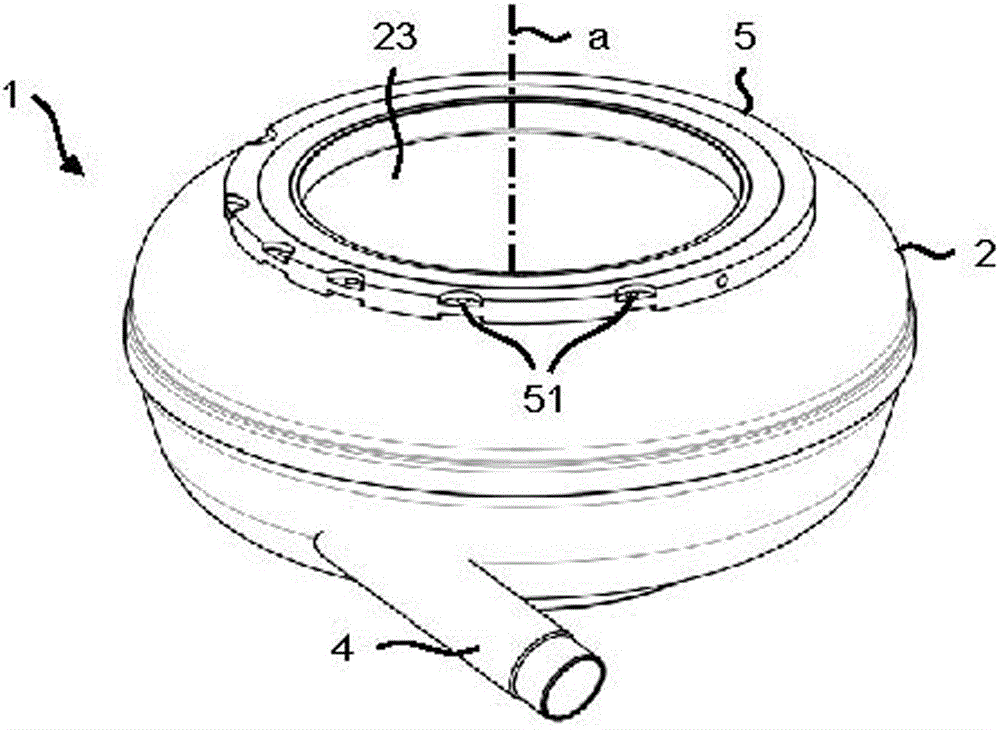

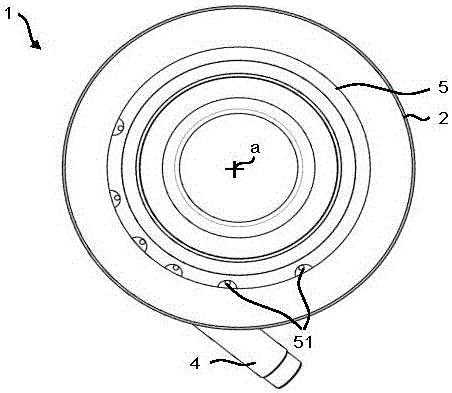

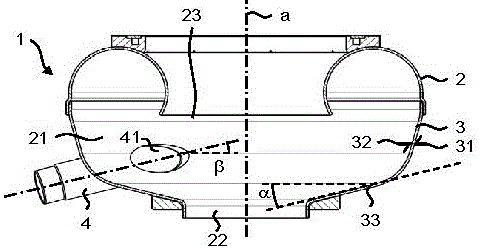

[0028] Figure 1 shows an embodiment of a device 1 for forming balls of yarn according to the invention in (a) perspective view, (b) plan view and (c) longitudinal section view. The device 1 forms a rigid unit in the sense that it does not comprise any parts movable relative to each other. It can therefore be called a fixed component.

[0029] The device 1 comprises a container 2 having an inner space 21 which is circularly symmetrical about a vertical axis a. In the embodiment of Fig. 1, the container 2 has substantially the shape of a part embedded in a ring. The container 2 is formed in the present embodiment by a thin wall 3, for example made of sheet metal, preferably steel or aluminium. The wall 3 thus defines an inner wall 31 and an outer wall 32 in the interior of the container 3 . The insert ring is defined by a circle arranged in a horizontal plane, the center point of which lies on the axis a. The inner space 21 is closed inwards and opened towards the inside, ie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com