BIM method applicable to positioning specially-shaped steel-concrete structural component

A technology of structural components and special-shaped steel, which is applied in special data processing applications, image data processing, instruments, etc., can solve problems such as inaccurate positioning, abnormal and complex building shapes, etc., and achieve the effect of improving engineering construction level and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below according to accompanying drawing and specific embodiment, this aspect is further described:

[0031] A BIM method applied to the positioning of special-shaped steel-concrete structural members described in the present invention includes the following steps:

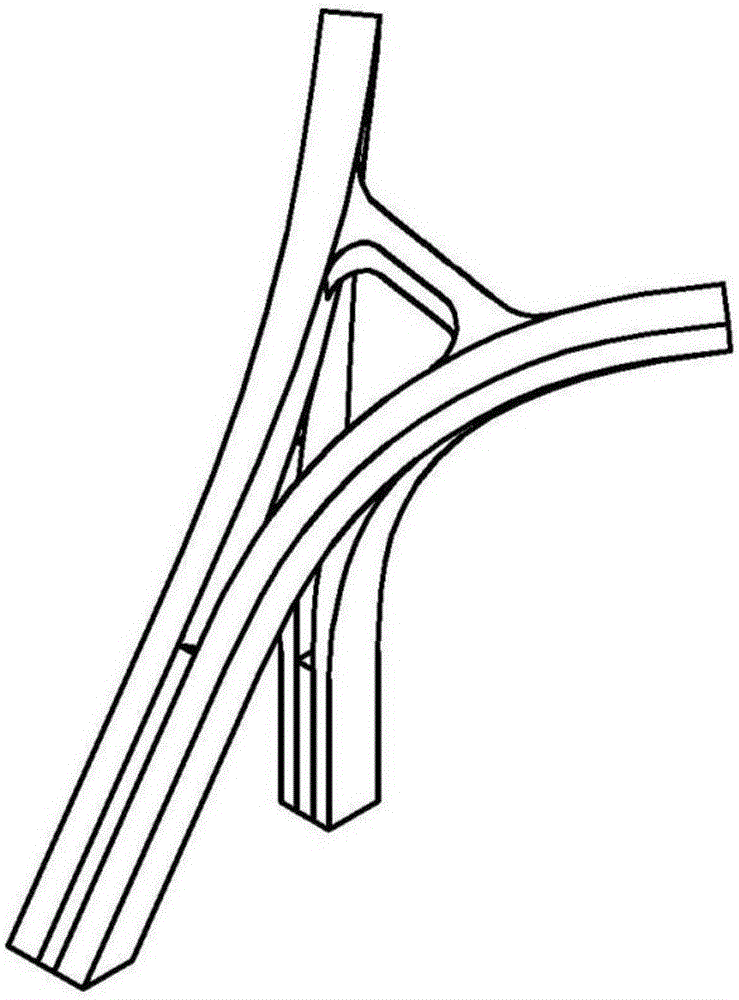

[0032] 1) Architectural design and computer three-dimensional construction of the Rhino model of the special-shaped steel-concrete structural member;

[0033] 2) Build a 3D BIM model with the Rhino model in the Revit model; after the design unit has designed the 3D model, due to the complexity of the structure, the drawn architectural design and construction drawings cannot guide the site to locate and construct. Therefore, according to the designer's Rhino 3D model and design drawings, the 3D model should be rebuilt in Revit software, and then fed back to the constructor for confirmation;

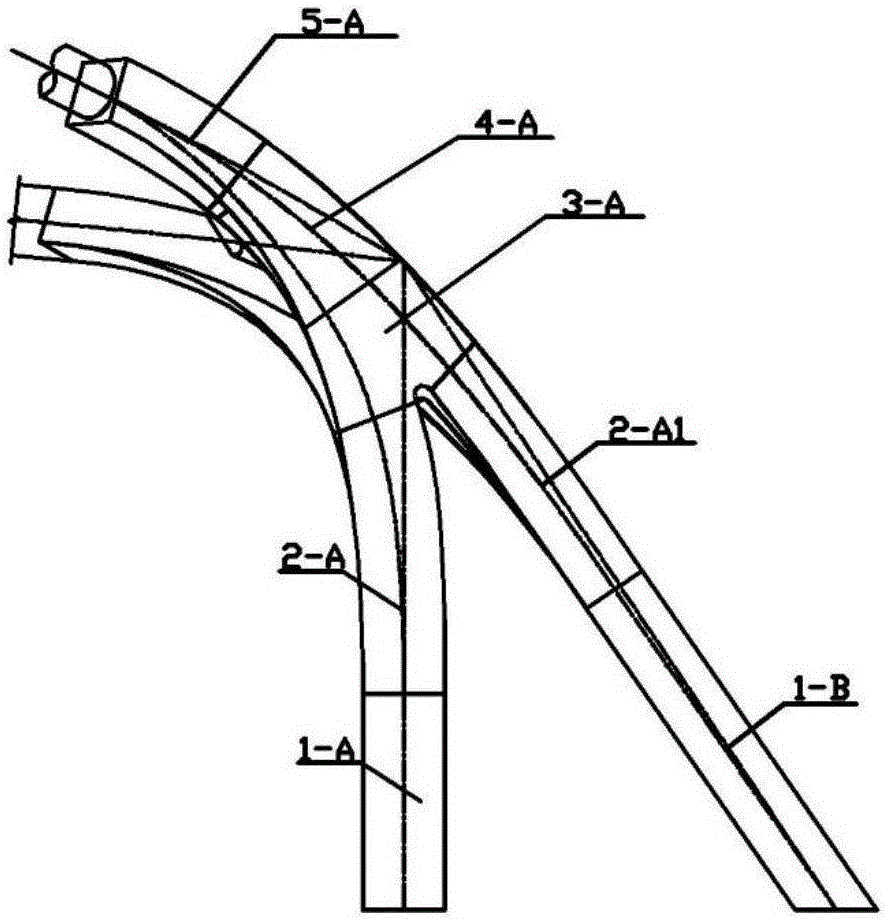

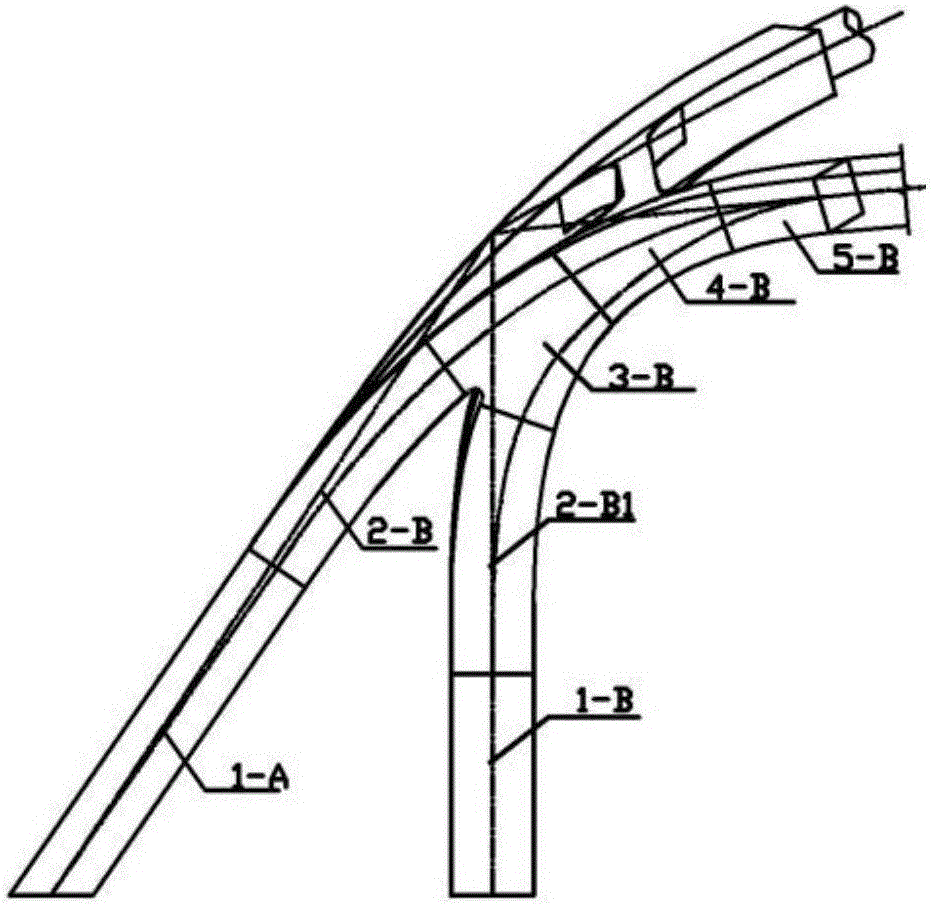

[0034] 3) if Figure 2-1 , as shown in 2-2, the BIM model is divided into 5 segments (1-A, 1-B; 2-A, 2A1, 2-B, 2-B1;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com