A kind of discharge printing composition

A discharge dyeing printing and composition technology, which is applied in the field of composition, can solve problems such as cumbersome process, slurry water pollution, harm to human health and ecological environment, and achieve the effects of simple operation, energy and cost saving, and full background color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

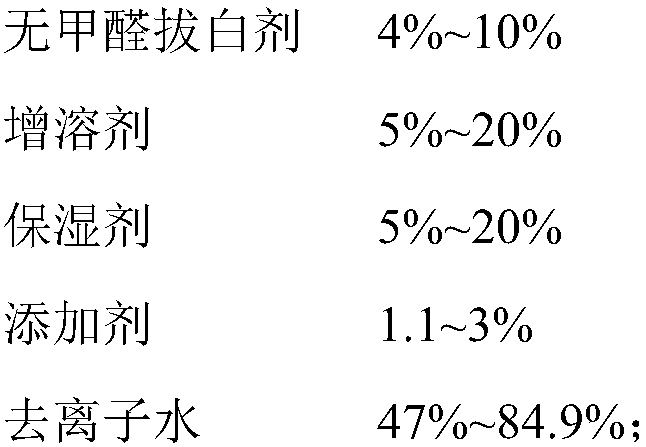

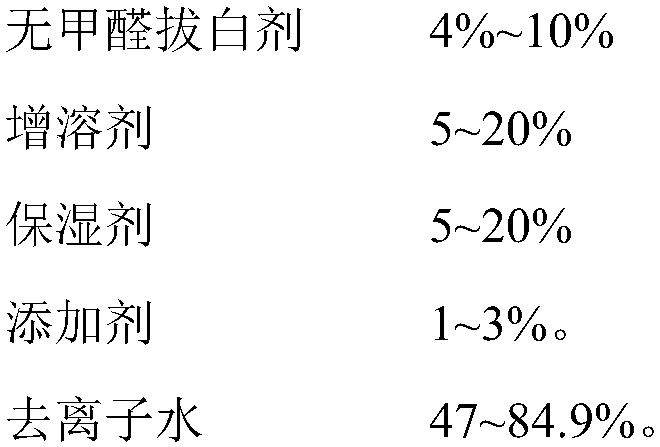

[0028] According to the ink composition, the mass fraction is: 8% formaldehyde-free whitening agent, 8% N-methylpyrrolidone, 6% caprolactam, 0.8% sodium hexametaphosphate, 1.2% Ph regulator and 76% deionized water mixed together and fully stirred for 30 minutes to obtain a mixed solution of whitening ink, during which the dissolution of each component can be accelerated by heating.

Embodiment 2

[0030] According to the ink composition, the mass fraction is: 4% formaldehyde-free whitening agent, 5% caprolactam and N-methylpyrrolidone mixture, 5% polyethylene glycol 400, 0.1% sodium hexametaphosphate, 1% Ph regulator and 84.9% deionized water is mixed together and fully stirred for 45 minutes to obtain a white ink mixed solution, during which heating can be used to accelerate the dissolution of each component.

Embodiment 3

[0032] The mass fraction according to the ink composition is: 10% formaldehyde-free whitening agent, 20% caprolactam, 20% polyethylene glycol 200, 0.5% disodium edetate / 2.5% Ph regulator and 47% The ionic water is mixed together and fully stirred for 60 minutes to obtain a whitening ink mixed solution. During this process, the dissolution of each component can be accelerated by heating.

[0033] Table 1

[0034]

[0035] The black ink was prepared, and the components of each example are listed in Table 2.

[0036] Example 1:

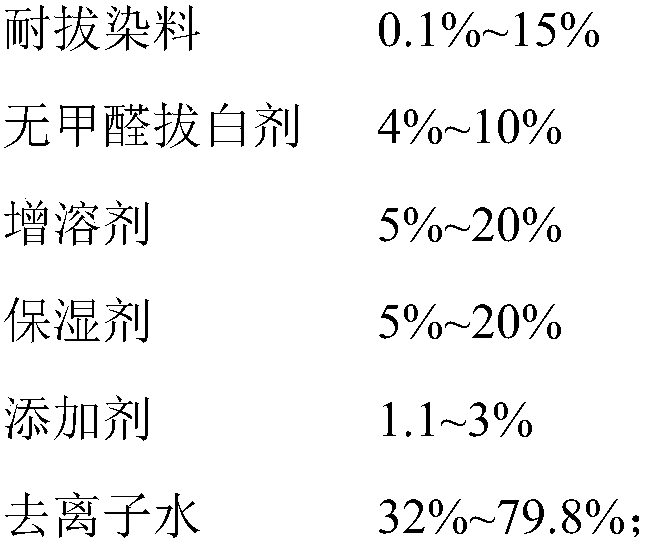

[0037] According to the ink composition, the mass fraction is: 0.1% anti-pulling dye, 4% formaldehyde-free whitening agent, 5% N-methylpyrrolidone, 5% caprolactam, 0.1% sodium hexametaphosphate, 1% Ph regulator and 79.8 % of deionized water were mixed together and fully stirred for 30 minutes to obtain a mixed black ink solution, during which heating could be used to accelerate the dissolution of each component.

[0038] Example 2:

[0039] Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com