Installation device for passenger car windscreen

A windshield and installation device technology, applied to windshields, motor vehicles, vehicle parts, etc., can solve the problems of low work efficiency, heavy workload, high installation cost, etc., to avoid damage, stabilize the vacuum degree, and improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

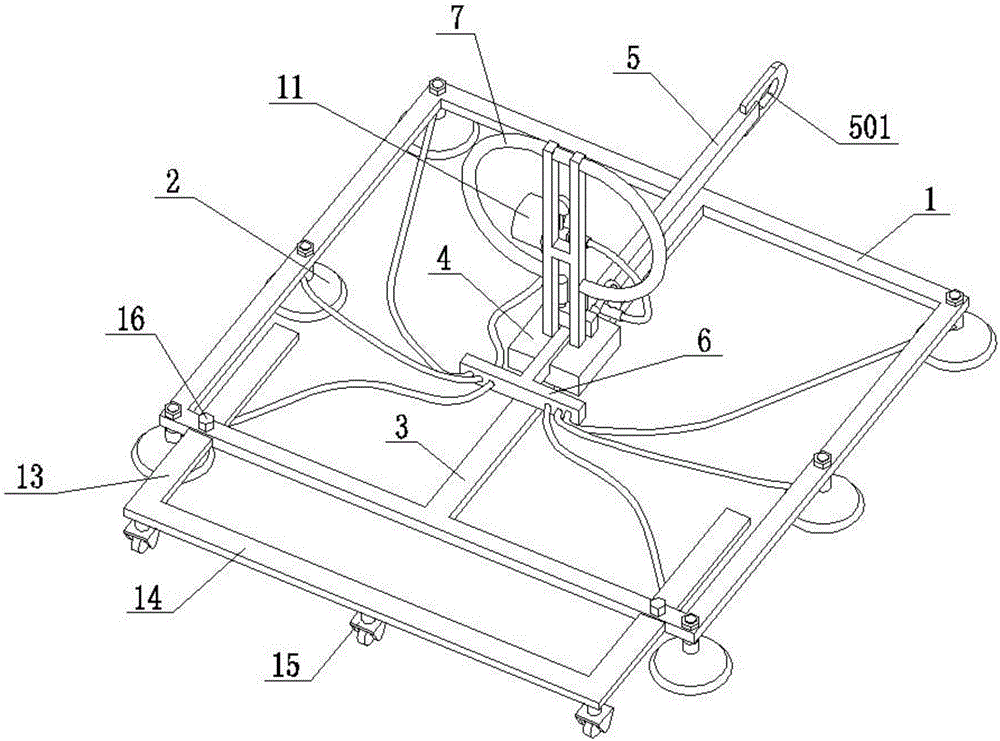

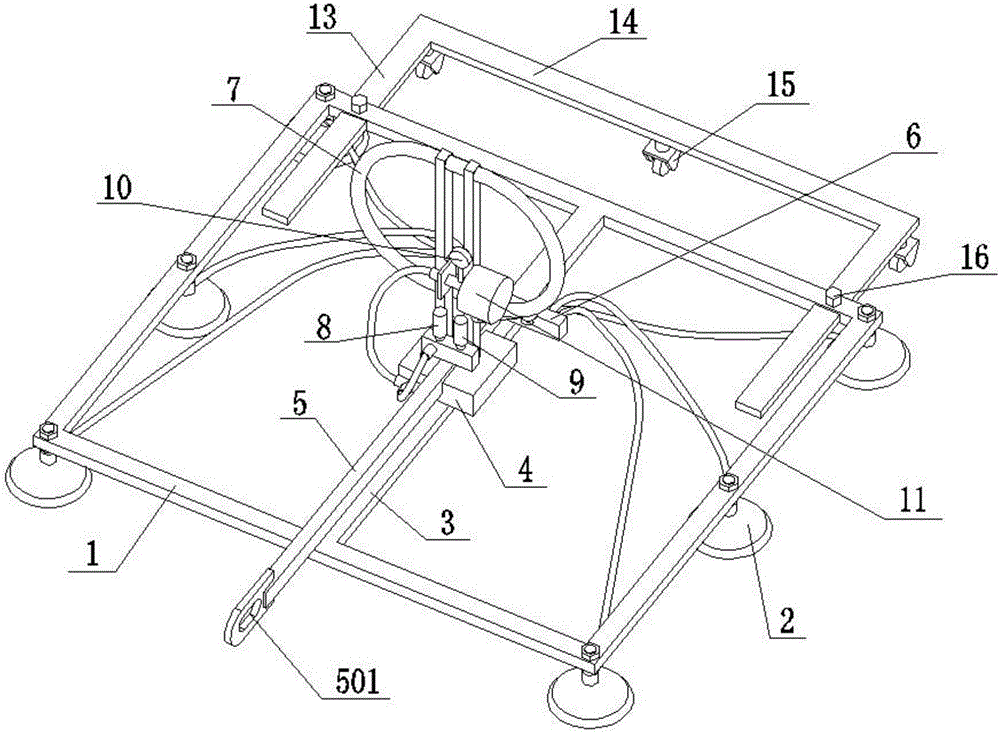

[0022] Such as Figure 1-4 As shown, the present invention provides a windshield installation device for passenger cars, comprising a square suction cup frame 1, three suction cups 2 are arranged on two opposite sides of the suction cup frame 1, and six suction cups 2 are evenly distributed on both sides of the suction cup frame 1. on the edge.

[0023] The suction cup 2 is connected to the suction cup frame 1 through a connecting rod 201, one end of the connecting rod 201 is connected to the suction cup 2, and the other end is fixed on the suction cup frame 1 by a fixing nut 202, and the connecting rod 201 between the suction cup 2 and the suction cup frame 1 is covered with a spring 203, Prevent the glass from being crushed due to excessive pressure when sucking the glass.

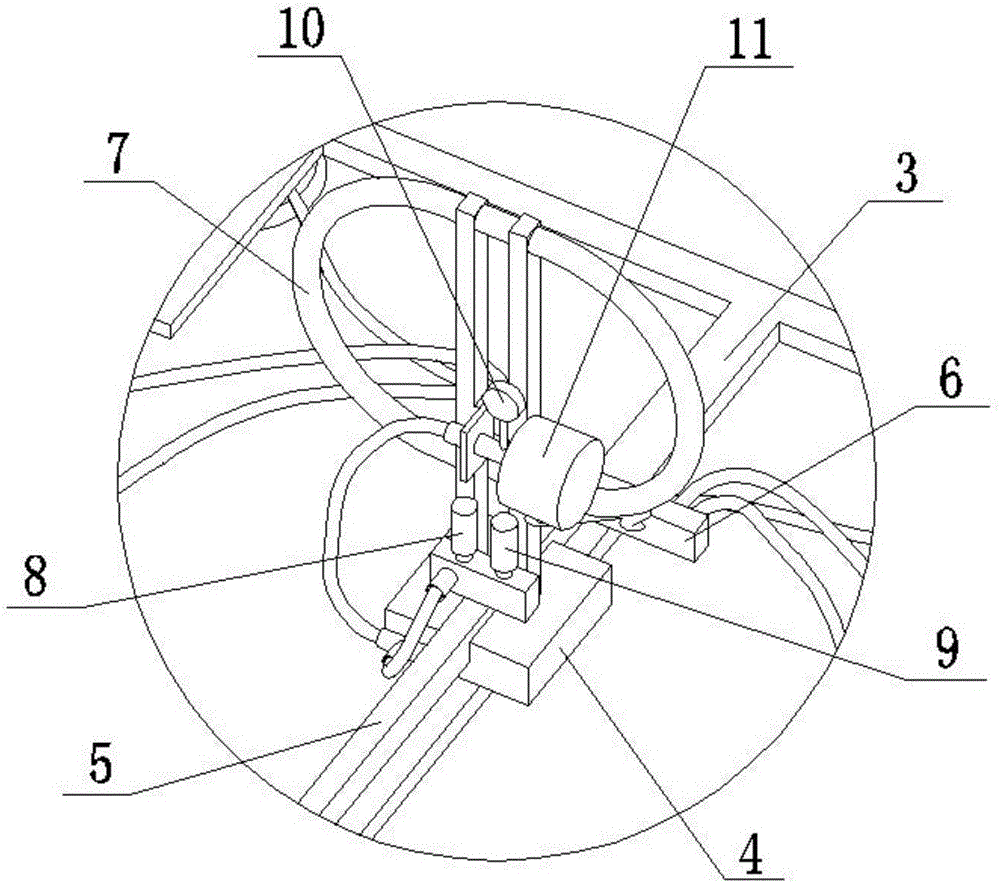

[0024] A supporting beam 3 is located in the middle of the suction cup frame 1, and a connecting block 4 is welded on the supporting beam 3. A T-shaped gas distributor 6 is arranged on one side of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com