Modeling method for in-furnace ash deposition model based on direct simulation Monte Carlo

A modeling method and fouling technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as powerlessness, excessive computing load and computer storage requirements, and describe the fouling deposition process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

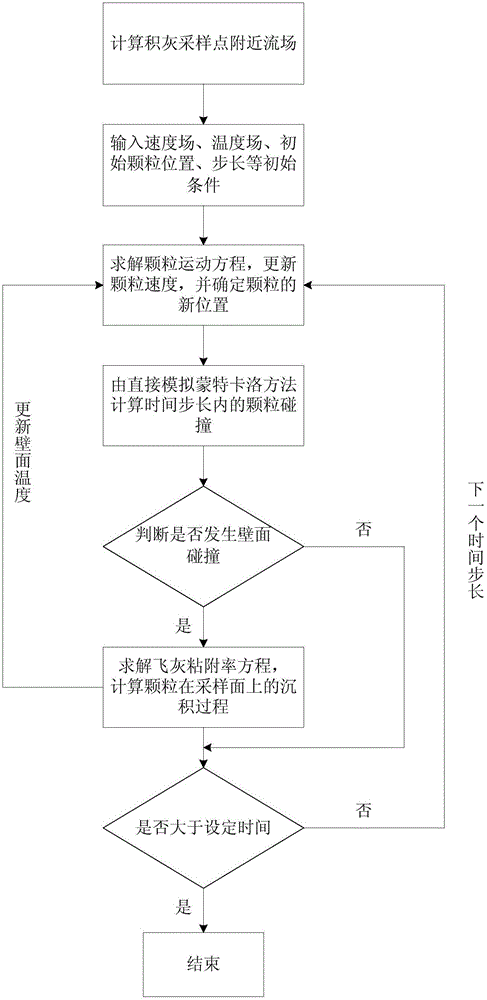

[0069] Concrete implementation method of the present invention is as follows:

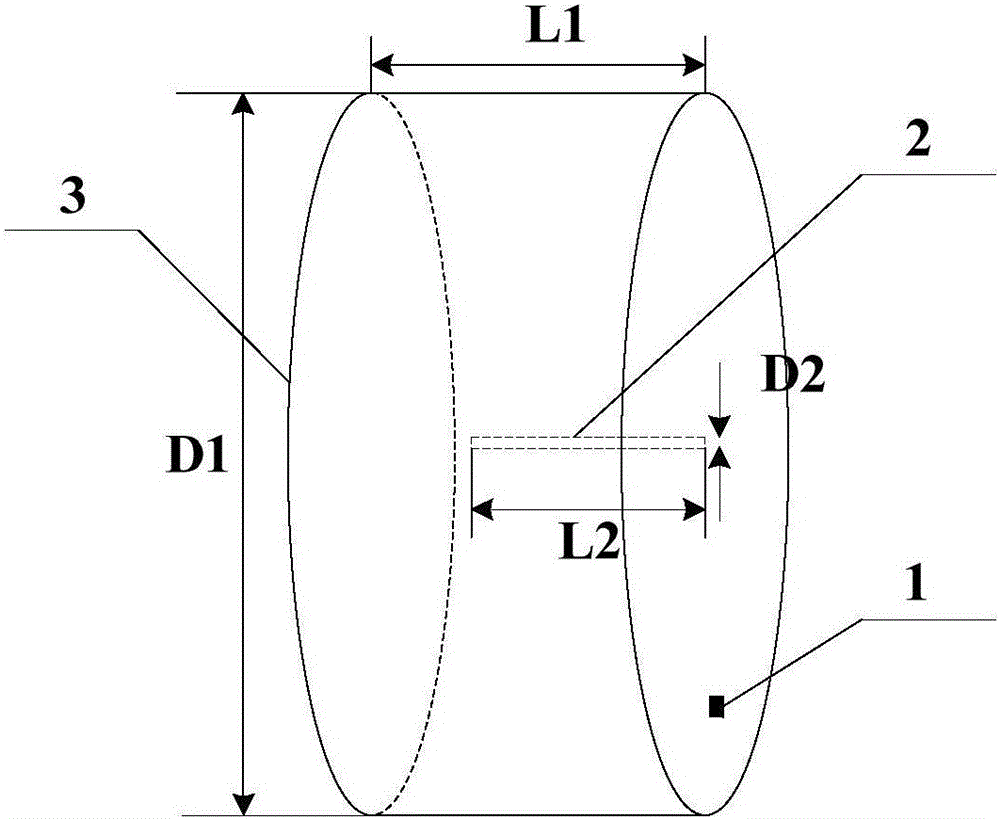

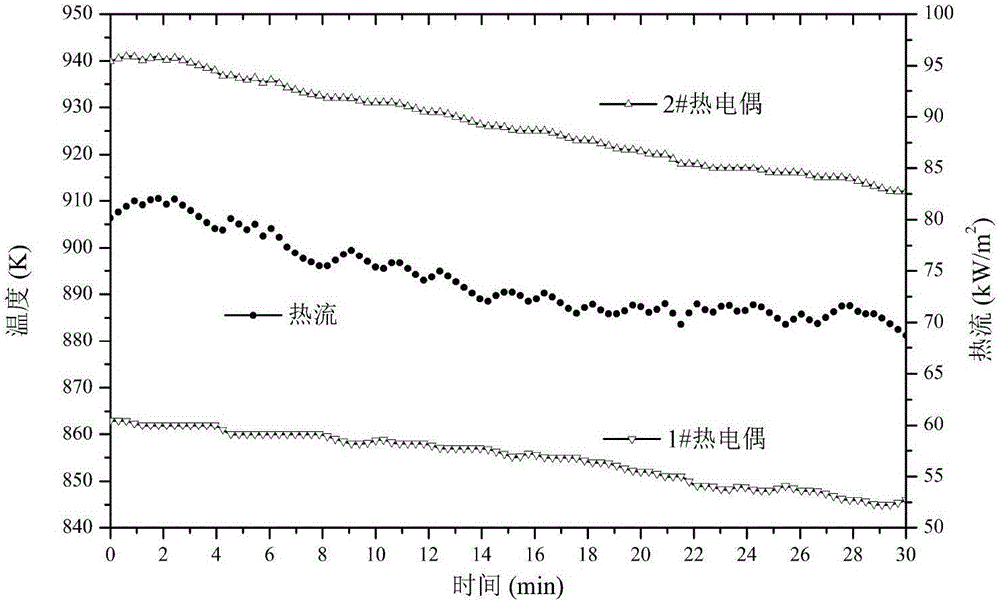

[0070] Taking a 660MW supercritical pulverized coal boiler as the research object, the ash sampling gun is inserted into the fire hole of a certain layer of the furnace, as shown in Fig. figure 2 shown. The sampling gun is composed of 3 parts, the gun head is a cylindrical alloy steel of 12CrMoV material, diameter D1=90mm, D2=3mm thickness L1=30mm, two K-type thermocouples are respectively buried in the thickness L2=28mm and the outer surface where the thermocouple readings are recorded separately via the two temperature displays. The experiment lasted 30 minutes, image 3 The recorded readings for the two thermocouples are used to obtain the heat flow according to equation (13).

[0071] Computational fluid dynamics method is used to calculate the flow field near the sampling point to obtain the velocity field near the sampling point, and then image 3 The heat flow data of the model is input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com