Camera lens

A camera lens and lens technology, applied in the field of camera lenses, can solve the problems of cost increase, lens increase, lens addition, etc., and achieve the effect of high imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

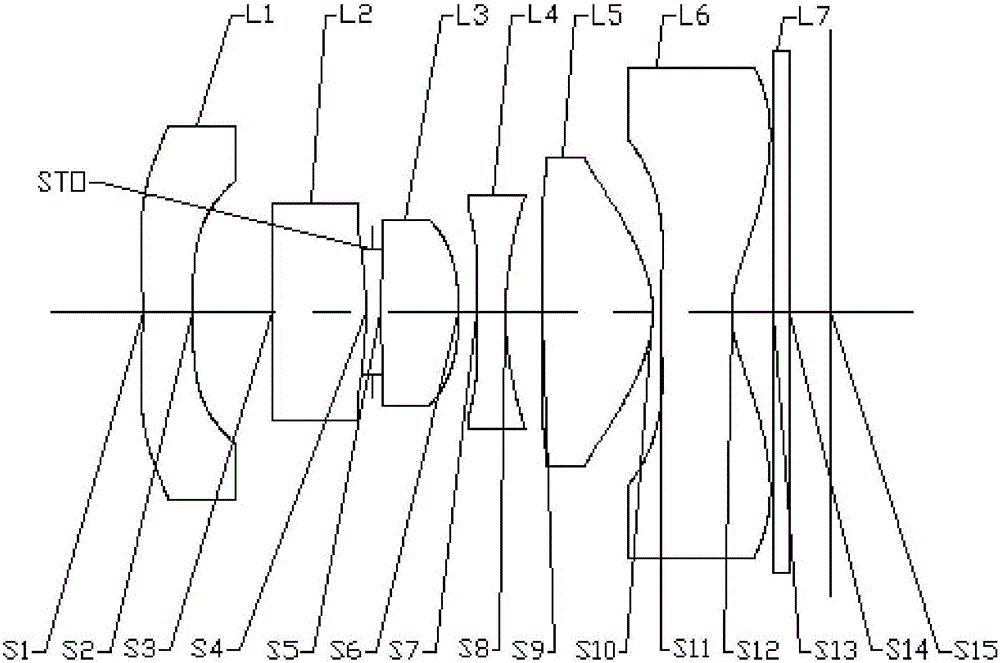

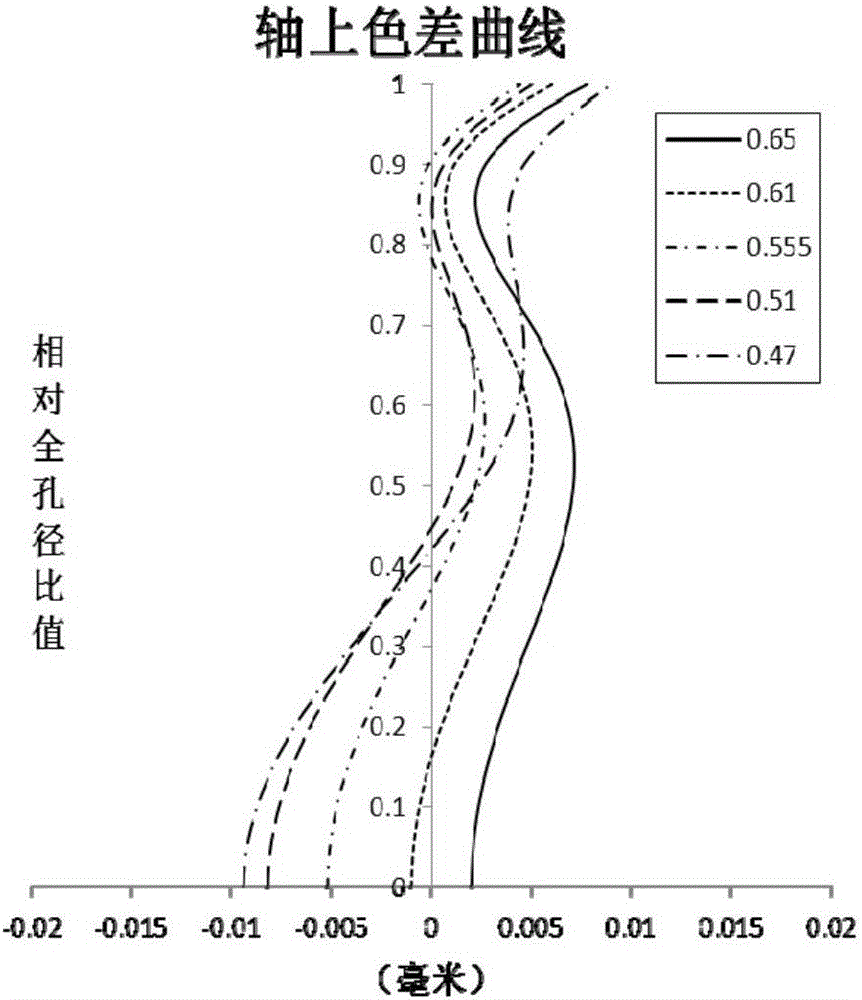

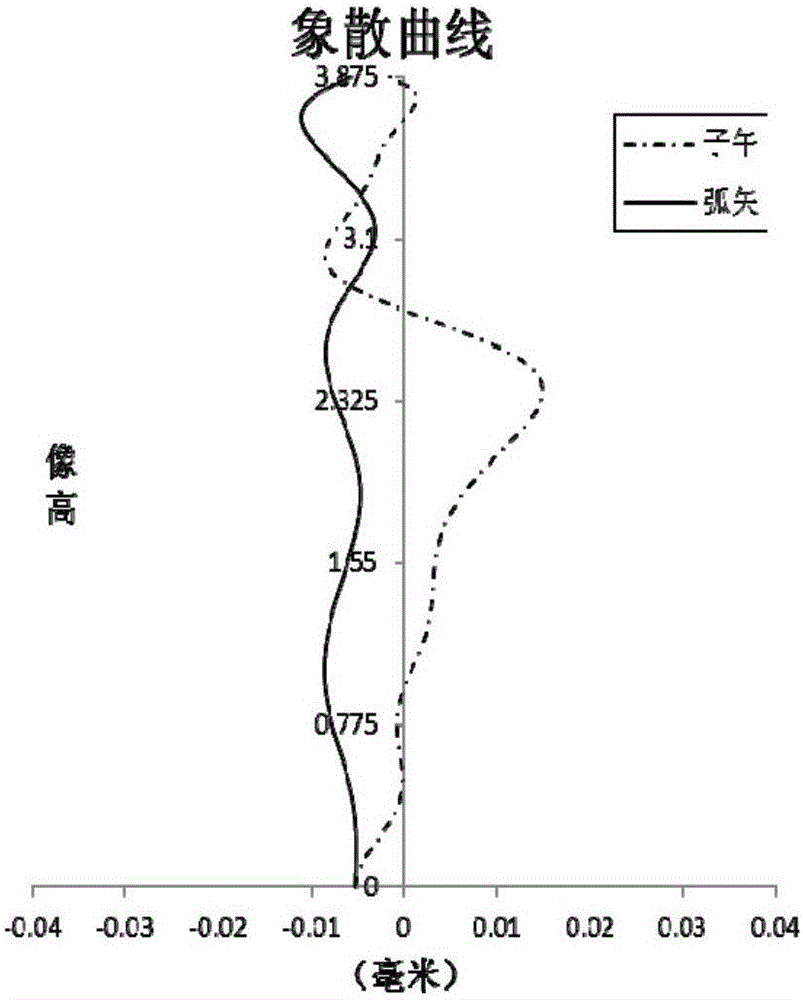

[0115] see Figure 1-5 , in embodiment 1, the camera lens meets the conditions of the following table:

[0116] Table 1

[0117] face number

Radius of curvature

thickness

Material

Conic factor

OBJ

spherical

endless

endless

S1

Aspherical

-7.7148

0.7015

1.535 / 55.78

-87.6627

S2

Aspherical

26.4563

1.1057

-99.9900

S3

spherical

endless

1.3200

1.755 / 52.32

S4

spherical

-5.9748

0.0960

STO

spherical

endless

0.1180

S5

Aspherical

11.1540

1.0901

1.535 / 55.78

-74.2030

S6

Aspherical

-3.8765

0.2529

6.0089

S7

Aspherical

10.5335

0.4000

1.640 / 23.53

46.5584

S8

Aspherical

3.6644

0.5124

-9.3315

S9

Aspherical

-50.0000

1.5523

1.535 / 55.78

-99.9900

S10

Aspherical

-1.5300

0.1084

-2.1876 ...

Embodiment 2

[0123] see Figure 6-10 , in embodiment 2, the camera lens meets the conditions of the following table:

[0124] Table 4

[0125] face number

Radius of curvature

thickness

Material

Conic factor

OBJ

spherical

endless

endless

S1

Aspherical

-8.5881

0.7000

1.535 / 55.78

-99.9900

S2

Aspherical

14.8963

1.0732

-21.6949

S3

spherical

254.2299

1.3200

1.754 / 52.43

S4

spherical

-6.0626

0.1723

STO

spherical

endless

0.0976

S5

Aspherical

10.7570

1.1203

1.535 / 55.78

-48.9231

S6

Aspherical

-3.8732

0.2519

6.0525

S7

Aspherical

10.5893

0.4739

1.640 / 23.53

45.3901

S8

Aspherical

3.6535

0.4714

-9.0167

S9

Aspherical

-57.1356

1.5363

1.535 / 55.78

-99.9900

S10

Aspherical

-1.6981

0.2185

-2.0629...

Embodiment 3

[0131] see Figure 11-15 , in embodiment 3, the camera lens meets the conditions of the following table:

[0132] Table 7

[0133] face number

Radius of curvature

thickness

Material

Conic factor

OBJ

spherical

endless

endless

S1

Aspherical

-8.7466

0.7095

1.535 / 55.78

-99.9900

S2

Aspherical

14.6280

1.0615

-21.8005

S3

spherical

-134.1816

1.3200

1.754 / 52.43

S4

spherical

-6.0489

0.2580

STO

spherical

endless

0.0576

S5

Aspherical

9.1272

1.0576

1.535 / 55.78

-55.3265

S6

Aspherical

-3.8289

0.2397

6.2426

S7

Aspherical

10.4414

0.4824

1.640 / 23.53

45.2233

S8

Aspherical

3.6251

0.4777

-8.5609

S9

Aspherical

-46.0621

1.5822

1.535 / 55.78

50.0000

S10

Aspherical

-1.5760

0.0767

-2.0476...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com