Strain measurement wire with two-dimensional code marks at two ends

A strain measurement and two-dimensional code technology, applied in the field of strain measurement wires, can solve the problems of high risk of error, unrealistic and efficient, and complicated correspondence between strain measurement points and resistance strain gauge ports, etc., so as to reduce workload and improve The effect of efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

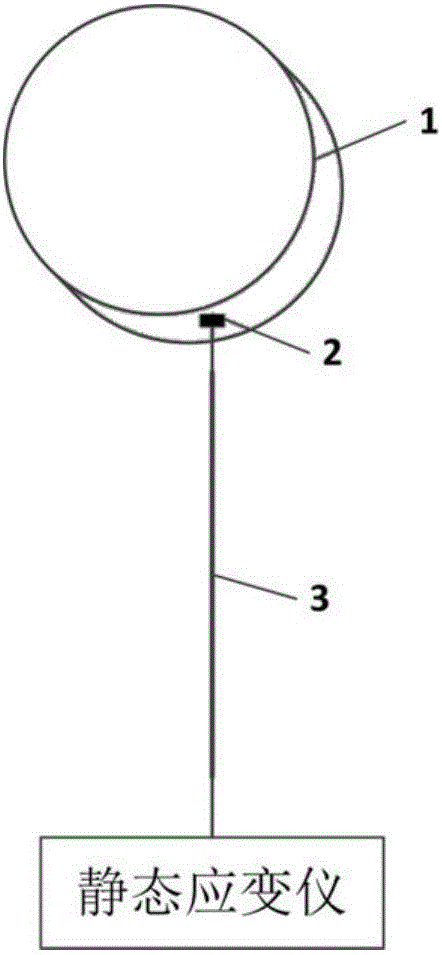

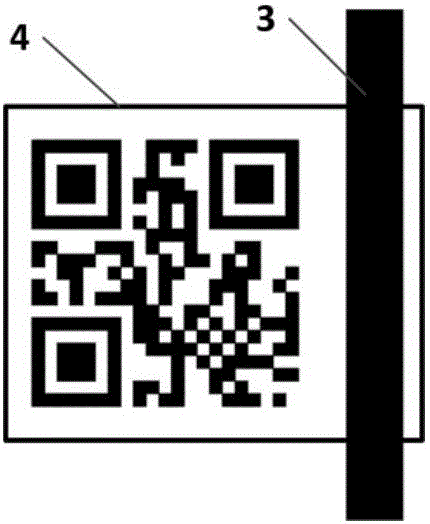

[0019] figure 1 is the structural diagram of the general wire connection test piece and the static strain gauge, while figure 2 For the structure diagram of the present invention and test piece and resistance strain gauge, refer to figure 2 , the arrangement of a strain measuring wire with two-dimensional code marks on both ends provided by the present invention is as follows: one end of the strain measuring wire 3 is connected to the strain gauge 2, and the strain gauge 2 is on the test piece 1, close to the strain gauge 2 There is a two-dimensional code mark 4 on the position, and at the experimental site, the two-dimensional code mark has a corresponding relationship with the number of the strain measuring point. The other end of the strain measurement wire 3 is connected to the resistance strain gauge, and the end close to the resistance strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com