a fe 2 o 3 Preparation method of nano-film coiled tube

A nano-film and nano-film technology, applied in the direction of iron oxide/iron hydroxide, iron oxide, etc., can solve the problems of incomplete template removal, cumbersome and complicated steps, polluted materials, etc., achieving convenient operation, simple preparation process, and scientific principle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

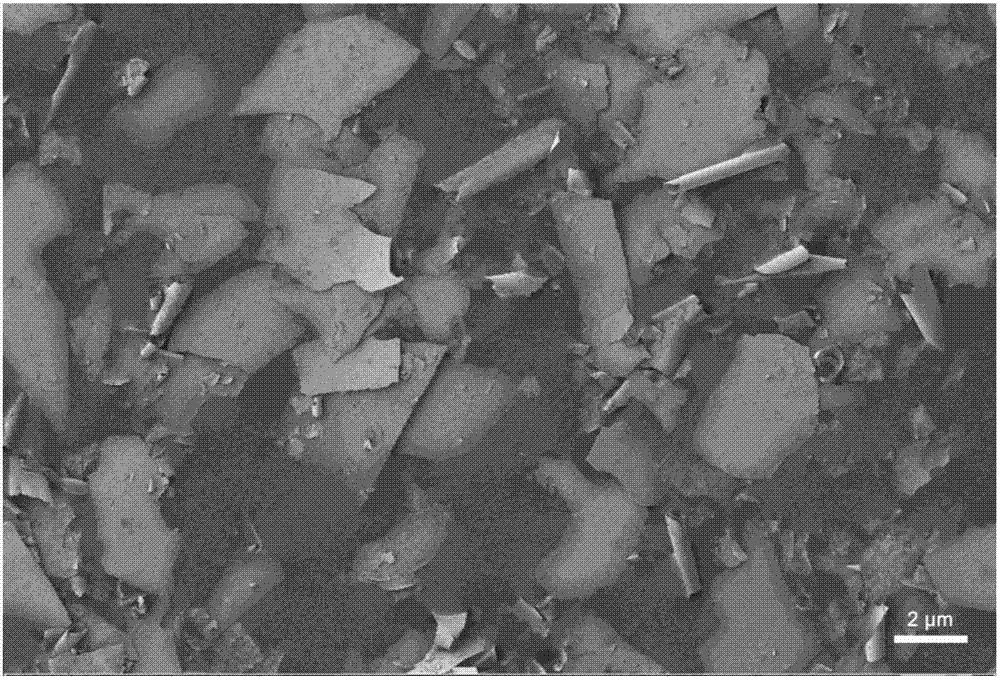

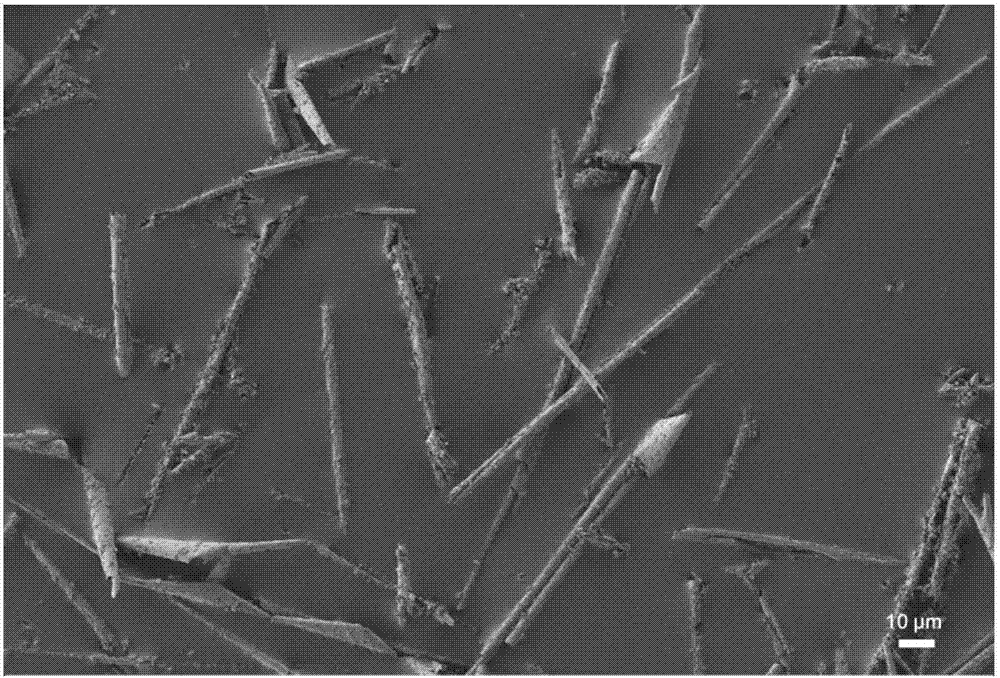

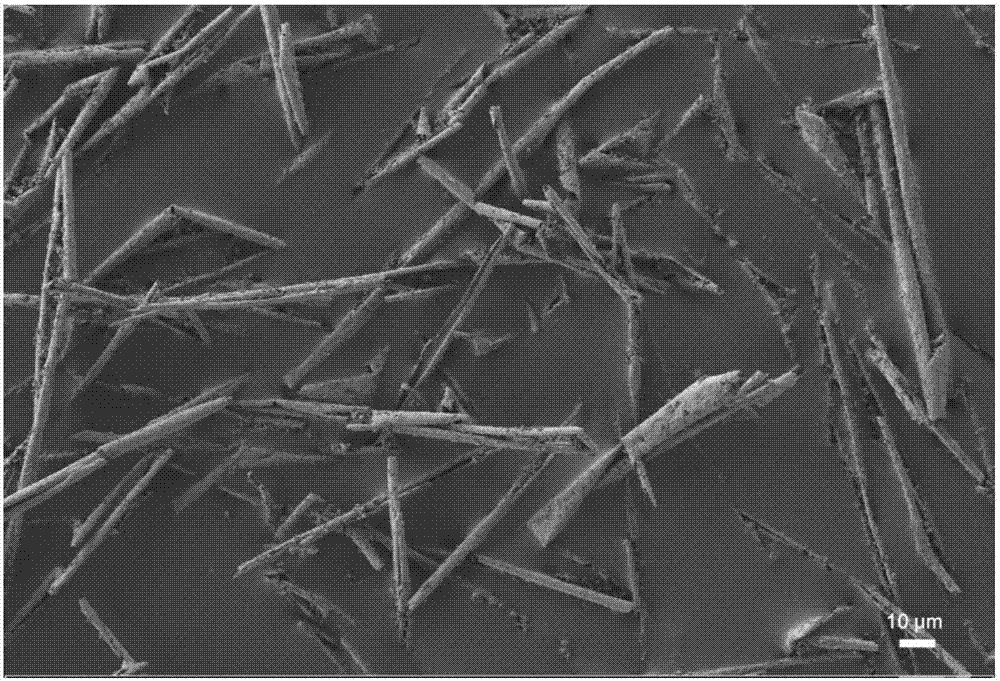

[0021] This embodiment prepares Fe 2 o 3 The specific process of nano-film crimping tube is as follows: first, deposit a layer of Al with a thickness of 50nm on the striped side of the aluminum foil using an electron beam evaporation coater 2 o 3 Nano film, a layer of Ti nano film with a thickness of 10nm, and a layer of Fe nano film with a thickness of 50nm; then put the aluminum foil in a NaOH solution with a concentration of 1M for 3h, and remove the Al by chemical corrosion. 2 o 3 and Ti nano-membrane, at the same time, Fe nano-membrane curled into a tubular structure under the released stress, and the resulting product was filtered and washed 3 times with deionized water, and then filtered and washed 3 times with ethanol and isopropanol successively, and then The filtered and washed product was subjected to CO 2 Supercritical drying for 12 hours to obtain Fe coiled tubes, and finally annealing the Fe coiled tubes in a tube furnace at 450 °C for 2 hours to prepare Fe ...

Embodiment 2

[0024] This embodiment prepares Fe 2 o 3 The specific process of nano-film crimping tube is as follows: first, deposit a layer of Al with a thickness of 50nm on the striped side of the aluminum foil using an electron beam evaporation coater 2 o 3 Nano film, a layer of 20nm thick Ti nano film, a layer of 20nm thick Fe nano film; then put the aluminum foil in a NaOH solution with a concentration of 1M for 3h, remove the Al by chemical corrosion 2 o 3 and Ti nano-membrane, at the same time, Fe nano-membrane curled into a tubular structure under the released stress, and the resulting product was filtered and washed 3 times with deionized water, and then filtered and washed 3 times with ethanol and isopropanol successively, and then The filtered and washed product was subjected to CO 2 Supercritical drying for 12 hours to obtain Fe coiled tubes, and finally annealing the Fe coiled tubes in a tube furnace at 450 ° C for 2 hours to prepare Fe 2 o 3 Nanomembrane crimp tube.

[...

Embodiment 3

[0027] This embodiment prepares Fe 2 o 3 The specific process of nano-film crimping tube is as follows: first, deposit a layer of Al with a thickness of 50nm on the striped side of the aluminum foil using an electron beam evaporation coater 2 o 3 Nano film, a layer of 20nm thick Ti nano film, a layer of 35nm thick Fe nano film; then put the aluminum foil into the NaOH solution with a concentration of 1M for 3h, remove the Al by chemical corrosion 2 o 3 and Ti nano-membrane, at the same time, Fe nano-membrane curled into a tubular structure under the released stress, and the resulting product was filtered and washed 3 times with deionized water, and then filtered and washed 3 times with ethanol and isopropanol successively, and then The filtered and washed product was subjected to CO 2 Supercritical drying for 12 hours to obtain Fe coiled tubes; finally, the Fe coiled tubes were annealed in a tube furnace at 450 °C for 2 hours to prepare Fe 2 o 3 Nanomembrane crimp tube. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com