Rotor compressor and slip sheet assembly thereof

A sliding vane and component technology, applied in the field of air supply structure, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

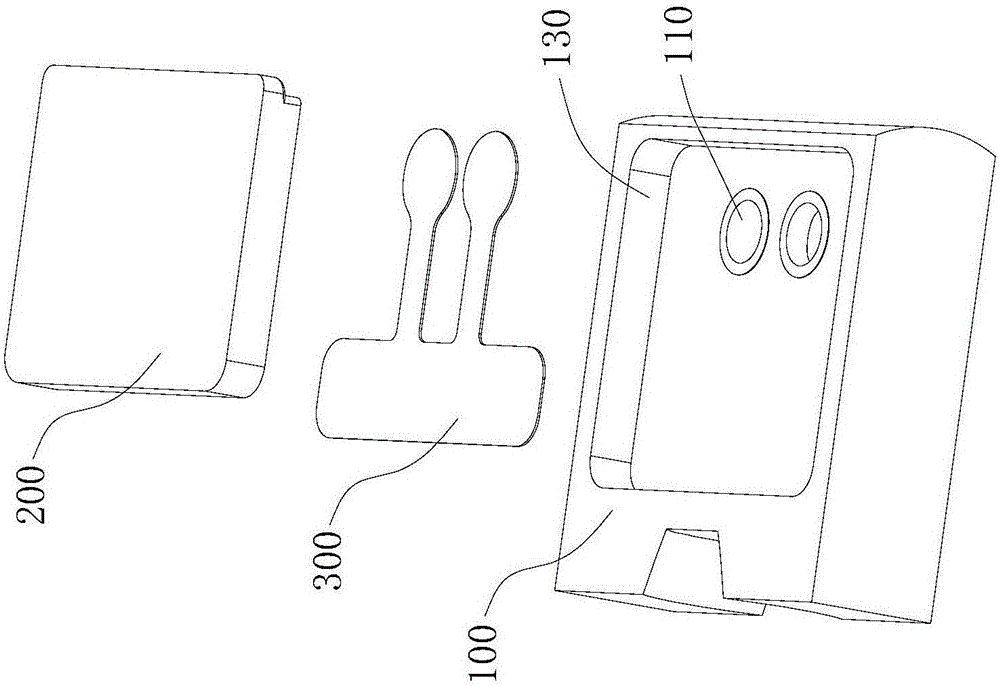

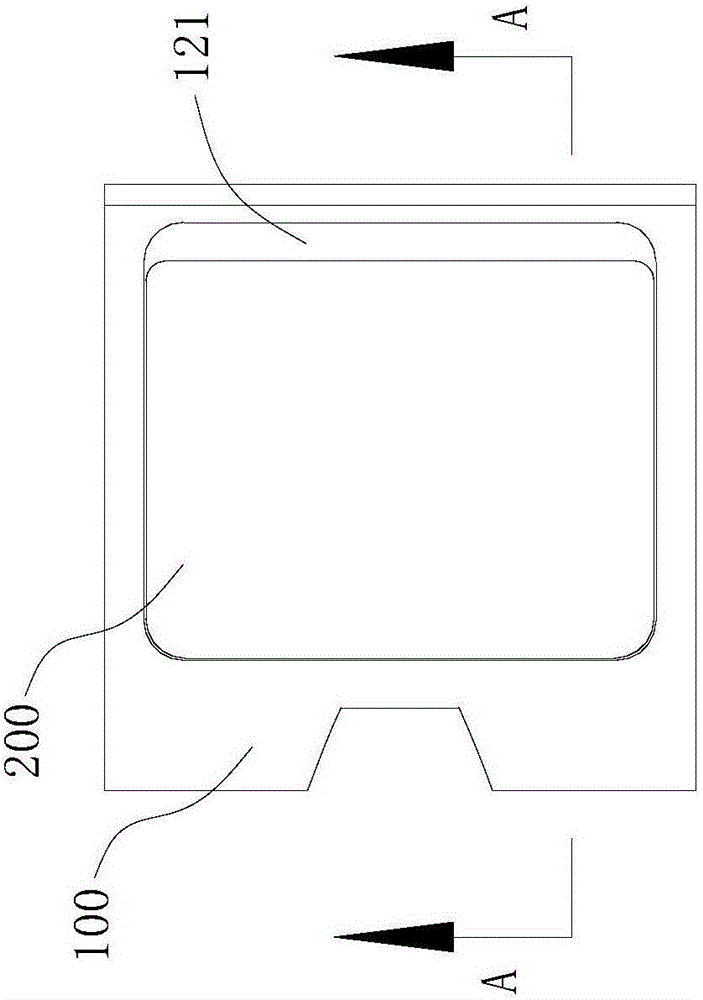

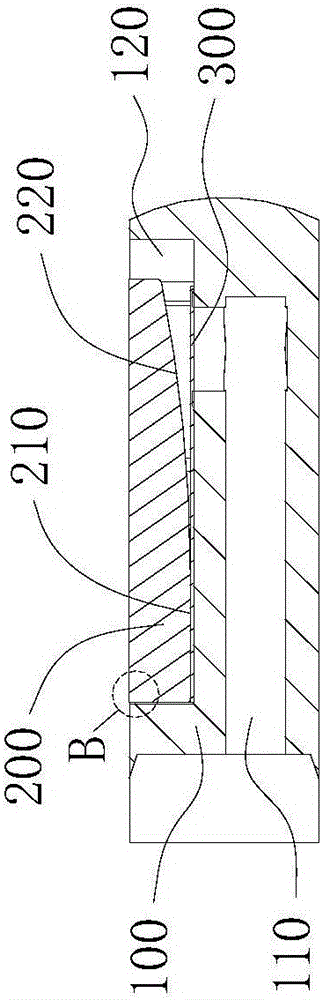

[0054] see Figure 1 to Figure 3 As shown, the first embodiment of the slide assembly of the present invention includes a slide body 100 , a baffle 200 and a valve plate 300 . There is an air supplement channel 110 inside the slider body 100; the baffle plate 200 is fixedly connected to one side of the slider body 100, and a back pressure chamber 120 is formed between the end of the baffle plate 200 and the slider body 100, and the back pressure chamber 120 There is an air supply outlet 121 communicating with the outside world, and the exhaust port of the air supply channel 110 is set corresponding to the back pressure chamber 120; the valve plate 300 is fixedly connected between the sliding plate body 100 and the baffle plate 200, and the movable end of the valve plate 300 It is located in the back pressure chamber 120 and correspondingly arranged on the exhaust port of the supplementary air passage 110; the movable end of the valve plate 300 has two stations for closing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com