Comb tooth type vehicle carrier transverse-moving device

A technology of traversing device and vehicle carrier, which is applied in the direction of building types, buildings where cars are parked, buildings, etc., and can solve the problems of safe operation accidents, intensified uncontrollable friction force, and comb-toothed vehicle carrier lateral movement. slow speed etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

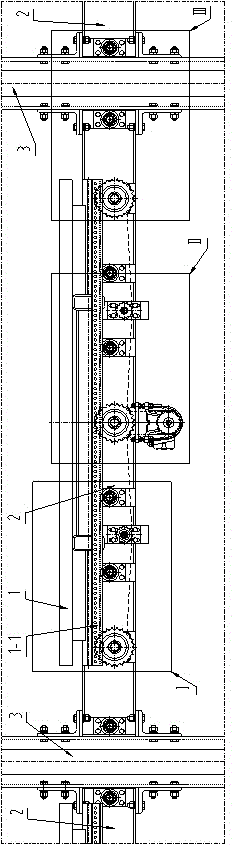

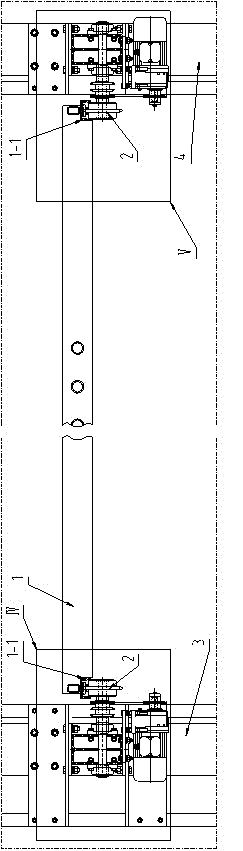

[0045] The present invention is applied in a three-dimensional garage with a steel structure, and the general frame of the three-dimensional garage includes a rear column assembly 3, a front column assembly 4 and cross beams 2-6.

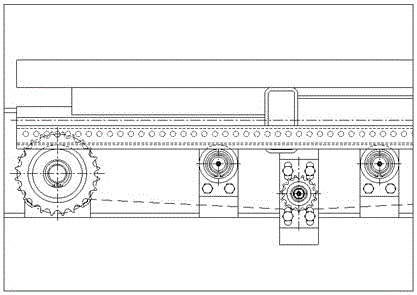

[0046] Reference attached Figures 1 to 7 , a comb-tooth type vehicle carrier traversing device, including a traversing transmission device 2 and a guide groove bracket mechanism 1-1; the traversing transmission device 2 is arranged on the front and rear sides of the three-dimensional garage general frame, and each row of beams 2- 6, the traversing transmission device 2 includes a traversing drive mechanism, a driving sprocket mechanism, two driven sprocket mechanisms and a plurality of small support wheel mechanisms, the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com