Positioning method of left rear side face vehicle door inner plate assembly

A positioning method and assembly technology, applied to doors, vehicle parts, transportation and packaging, etc., can solve the problems of cumbersome, cumbersome, and many processes in the production process, and achieve the effect of improving production efficiency and reducing positioning processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

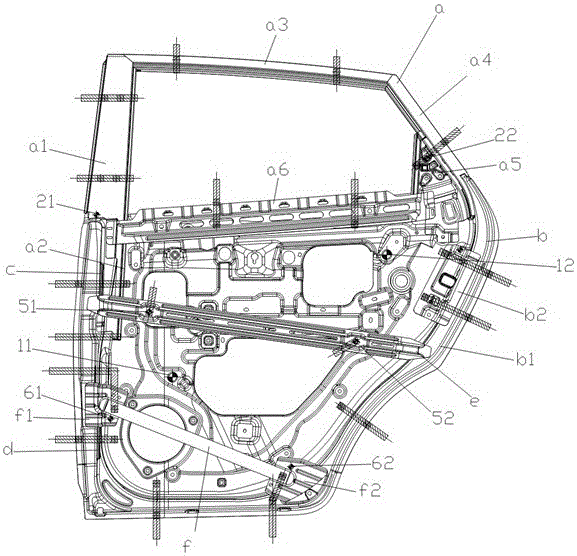

[0016] With reference to the accompanying drawings, a method for positioning the inner panel assembly of the left rear side door includes the following steps:

[0017] 1) Locate the door inner panel assembly b: place the door inner panel assembly b on the lower mold, and set the two door inner panel positioning pins 11, 12 on the lower mold, and the two door inner panel positioning pins 11, 12 The connection direction and the transverse direction of the door inner panel assembly b are arranged at an angle. The door inner panel assembly b is located at the positions of the positioning pins 11 and 12 of the two door inner panels. The holes are arranged correspondingly to the positioning pins 11 and 12 of the inner panels of the two doors;

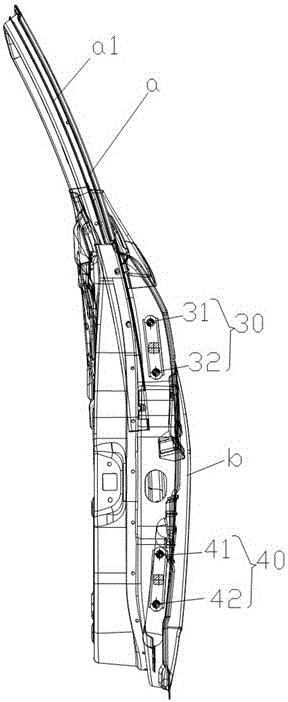

[0018] 2) Position the upper frame assembly a: place the upper frame assembly a on the door inner panel assembly b, and set the lower mold on the position of the door B-pillar a1 and the triangular window panel a5 where the upper frame assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com