Flow speed measurement method and flow speed measurement system

A flow rate measurement and flow rate technology, which is applied in the field of flow rate measurement and flow rate measurement system, can solve the problems of inaccurate measurement, incapable conduction of steam heat, and inability of temperature sensor to detect temperature well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

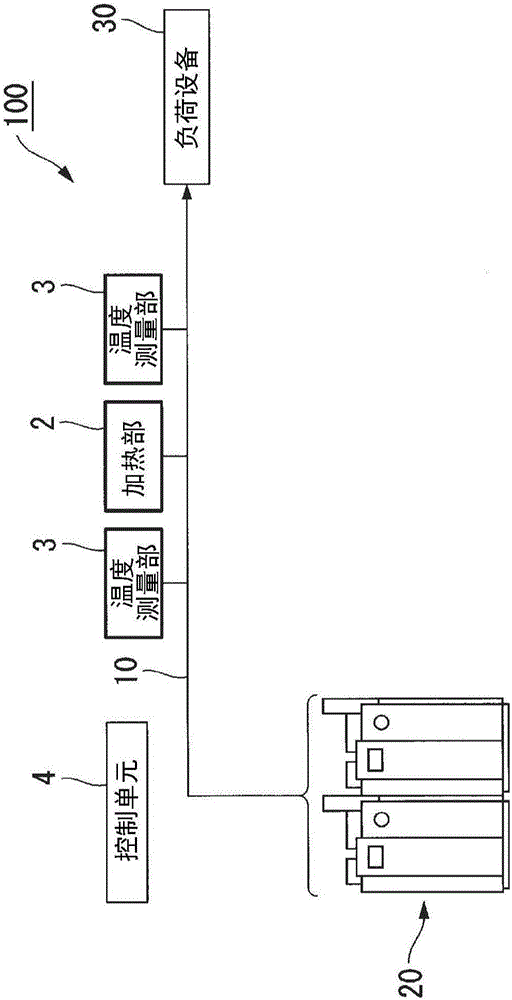

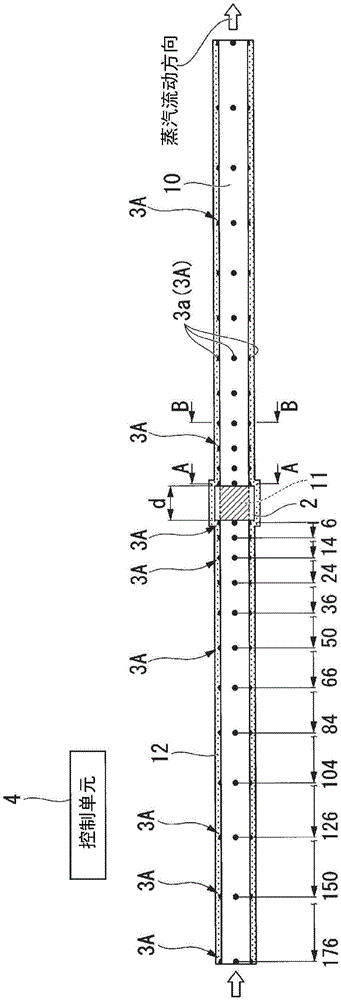

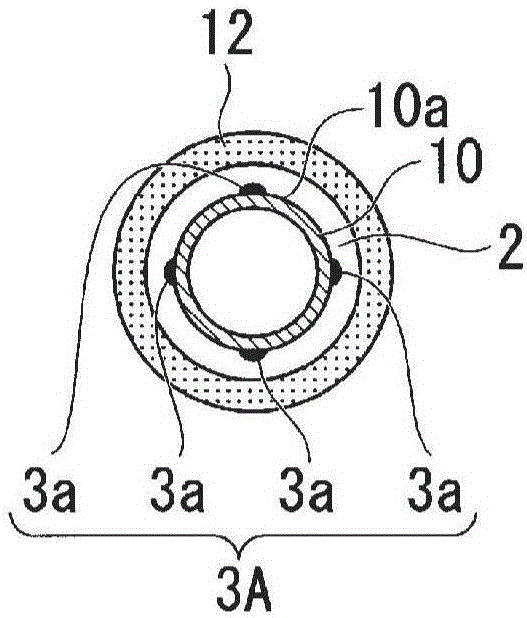

[0032] Hereinafter, several embodiments of the present invention will be described with reference to the drawings. The flow rate measurement system of the present embodiment is capable of measuring, for example, the flow rate of a thermal fluid (for example, steam) flowing in a pipe disposed between a steam production device such as a boiler and a load facility.

[0033] figure 1 It is a schematic configuration diagram showing the flow velocity measurement system of this embodiment. Figure 2A to Figure 2C It is a block diagram showing a main part of the flow velocity measurement system of this embodiment.

[0034] Such as figure 1 As shown, the flow velocity measurement system 100 of this embodiment includes: a heating unit (heat exchanger) 2 , a temperature measurement unit 3 , and a control unit (flow velocity calculation unit) 4 . exist figure 1 Among them, the pipe 10 is disposed between the steam production device 20 (boiler, etc.) and the load facility 30 . The ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com