Throttling expansion type dense-tooth steam seal

A throttling expansion and steam seal technology, applied in the direction of leakage prevention, engine components, machines/engines, etc., can solve problems such as inability to prevent friction, poor sealing performance, and easy vibration of the shaft, and achieve the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

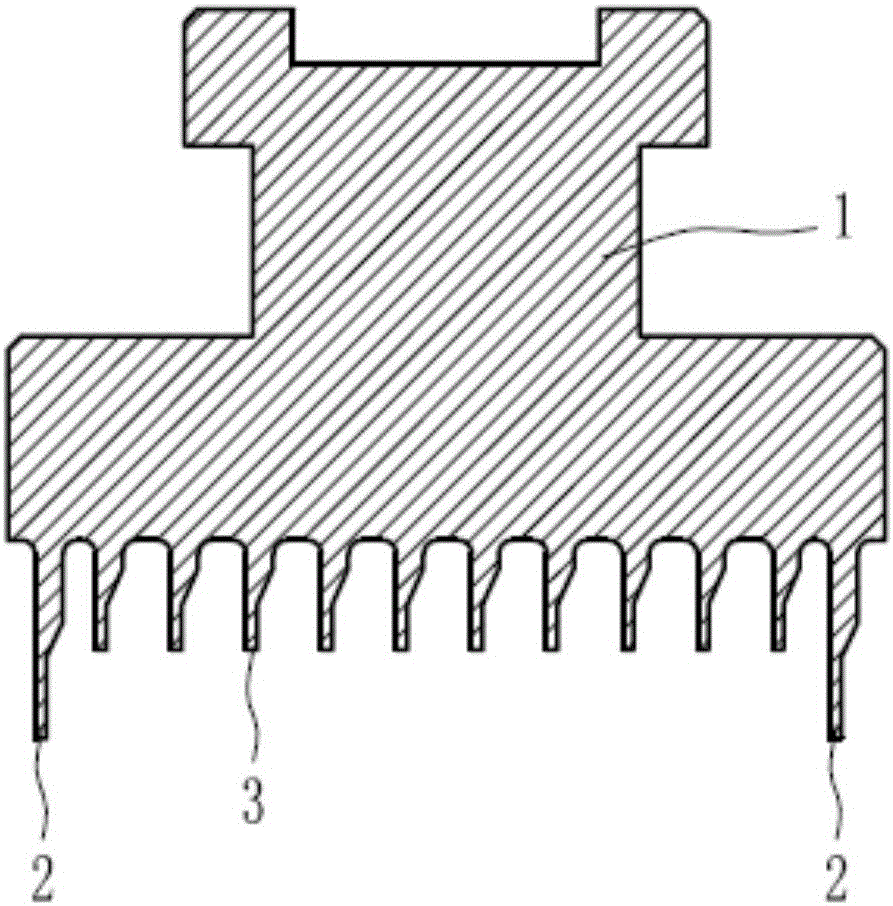

Embodiment 1

[0023] Such as figure 1 As shown, the throttling expansion dense gear seal is composed of several sections (generally 4 or more sections) of seal rings connected end to end. The steam seal ring includes a ring body 1, and at least two high-tooth sealing strips 2 are arranged on the peripheral surface of the ring body 1 opposite to the rotor. In this embodiment, two sealing strips 2 are used as examples. A plurality of low-toothed sealing strips 3 are densely arranged between the above-mentioned high-toothed sealing strips 2 to form densely toothed groups. The number of low-toothed sealing strips 3 in each densely toothed group can be determined according to the wide band of the ring body and the structure of the sealed part of the rotor. Properly set, generally there are at least 5 low-tooth sealing strips for each dense tooth group.

[0024] For the convenience of machining, the low-toothed sealing strips 3 densely arranged between two adjacent high-toothed sealing strips 2 ...

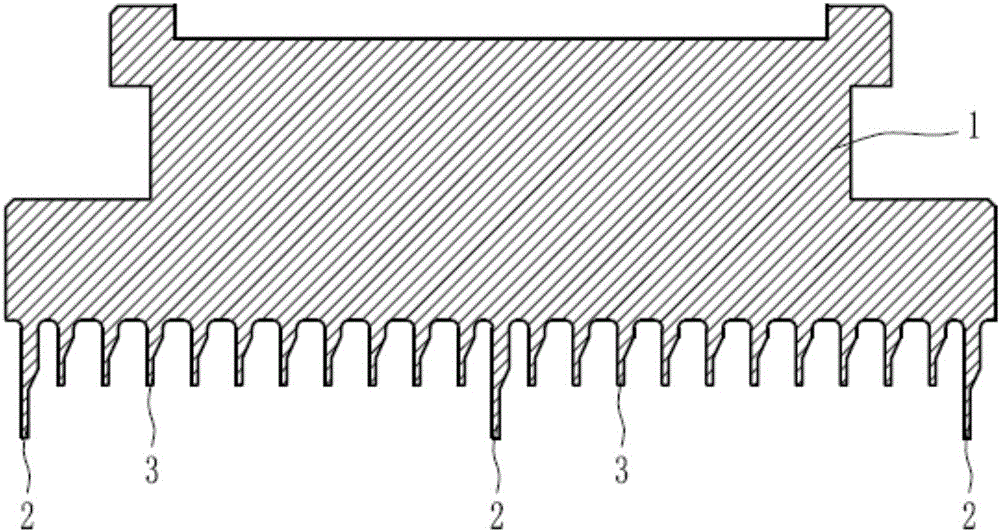

Embodiment 2

[0027] refer to figure 2 , the structural principle of this embodiment is basically the same as that of Embodiment 1, and the only difference is that three high-tooth sealing strips 2 are arranged on the circumferential surface of the ring body 1 opposite to the rotor, and the adjacent two high-tooth seals A plurality of low-toothed sealing strips 3 are densely arranged between the strips 2, and the axial gap between two adjacent low-toothed sealing strips 3 is about 2.5 mm.

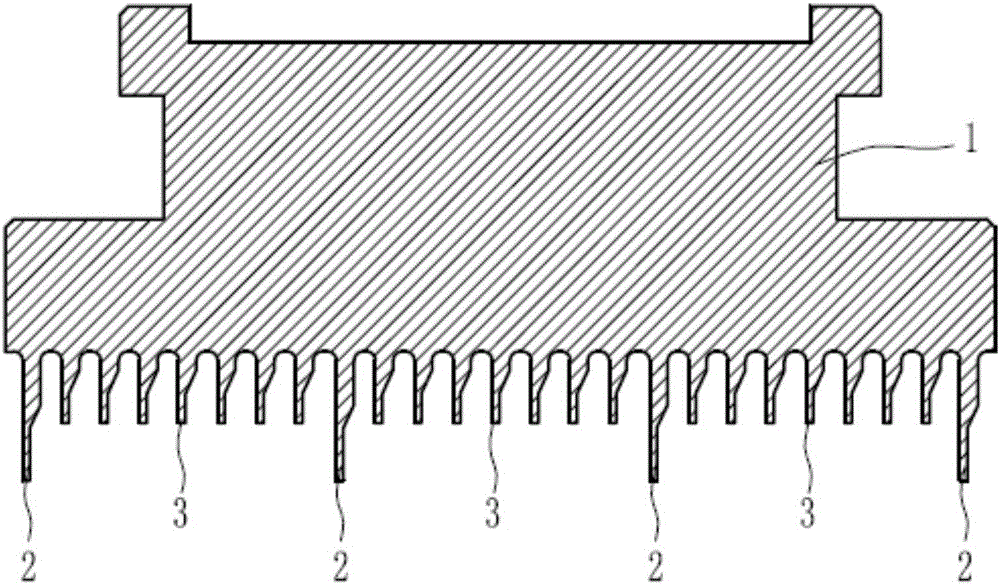

Embodiment 3

[0029] refer to image 3 , the structural principle of this embodiment is basically the same as that of Embodiment 1, and the only difference is that four high-tooth sealing strips 2 are arranged on the circumferential surface of the ring body 1 opposite to the rotor, and the adjacent two high-tooth sealing strips A plurality of low-toothed sealing strips 3 are densely arranged between the sealing strips 2 , and the axial gap between two adjacent low-toothed sealing strips 3 is about 2.0 mm.

[0030] Experiments have proved that the steam leakage of this dense toothed steam seal is only 20% to 30% of the original comb-toothed steam seal. It has the advantages of good sealing performance and simple and reasonable structure. It is suitable for replacing and upgrading the dynamic seal of the existing steam turbine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com