Three-dimensional rotary storage bin

A rotary and storage bin technology, applied in the field of straight steel bar storage equipment, can solve the problems of single discharge method, large floor area, and low degree of automation, and achieve safe and reliable structure, small floor area, and space saving The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

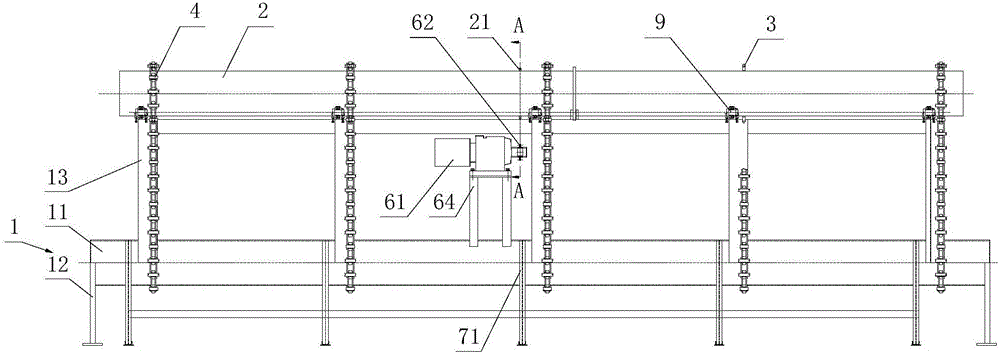

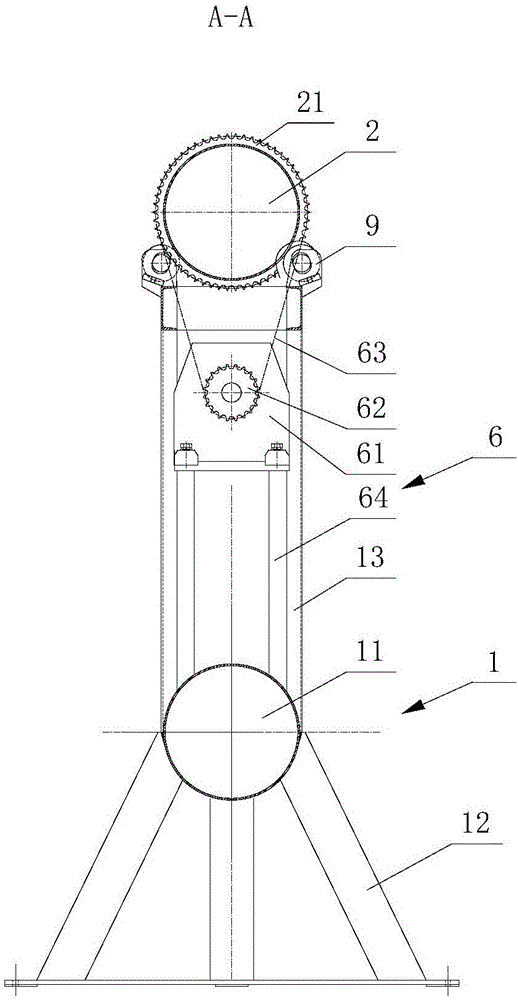

[0025] The invention provides a three-dimensional rotary storage bin, such as Figure 1-3 As shown, it includes a support frame 1, a rotating drum 2, a transport sprocket 3, a transport chain 4, a storage arm 5, a driving device 6, a material guide 71 and a control device (not shown) connected to the driving device 6 ,in:

[0026] The support frame 1 includes a cylinder 11, and a support seat 12 is fixed under the two ends of the cylinder 11. The length of the steel bars 8 to be stored is less than the distance between the two support seats 12, and they are arranged at equal intervals along the length direction of the cylinder 11. There are multiple sets of support columns 13, and each set of support columns 13 is symmetrically fixed on both sides of the cylinder 11, and one end of each support col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com