An online monitoring system for rubber lining integrity

A monitoring system and integrity technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as equipment function failure, leakage, safety issues, etc., and achieve the effect of reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

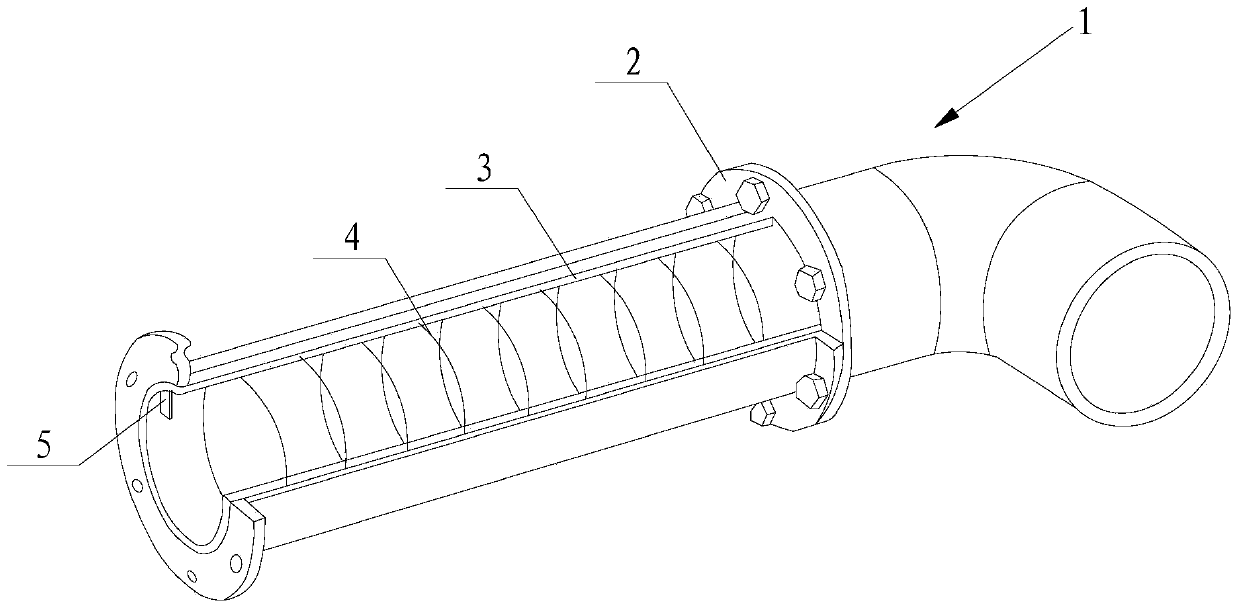

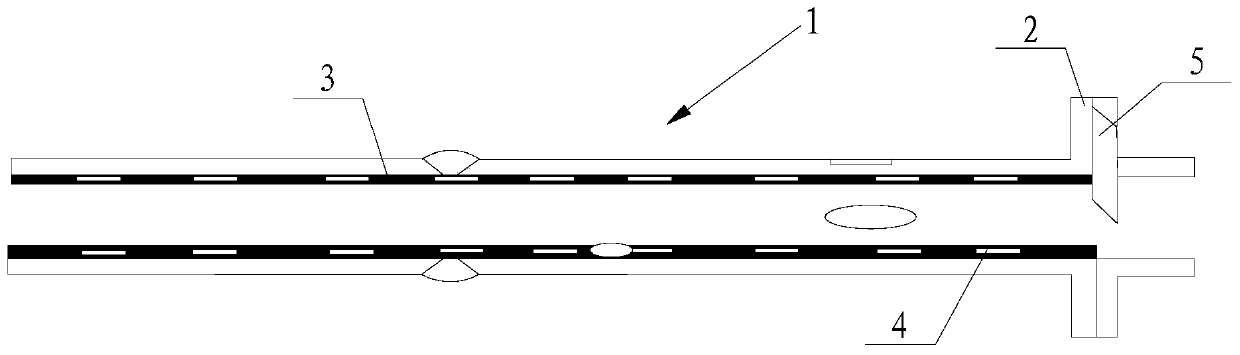

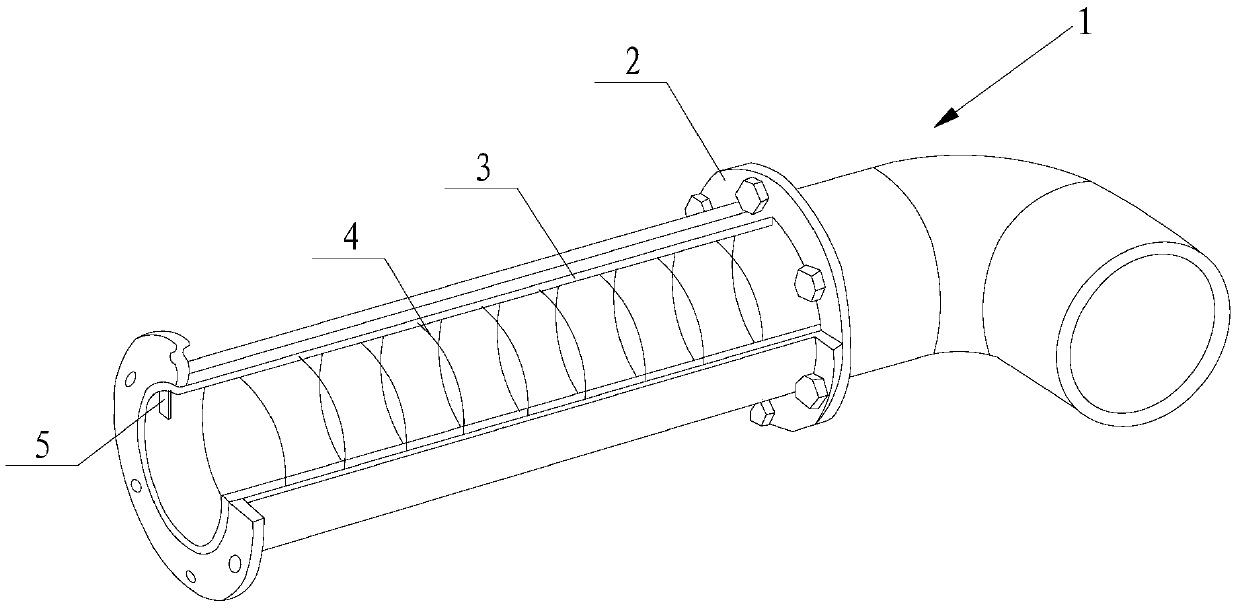

[0013] Such as figure 1 and figure 2 The online monitoring system for rubber lining integrity shown mainly includes a first sensor 4 and a second sensor 5 .

[0014] Among them, the online monitoring system for rubber lining integrity is usually installed in pipelines 1 that may be corroded in industries such as electric power, chemical industry, and nuclear power plants. Multiple pipelines 1 are connected by flanges 2 installed at their ends to form a pipeline system. The glue 3 is correspondingly installed on the inner walls of these pipes 1 . There are multiple first sensors 4, which are embedded in the rubber lining 3 and arranged in sequence along the axial direction of the pipe 1; they are rubber lining integrity monitoring sensors for monitoring the integrity of the rubber lining. There are also multiple second sensors 5, each of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com