A method for preparing porous carbon spheres from ripe sweetgum tree fruit and its adsorption application

A liquidambar and porous carbon technology, which is applied in the field of preparing porous carbon balls, can solve the problems of high preparation cost and complicated preparation conditions of porous carbon materials, and achieves the effect of simple method and convenient storage and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

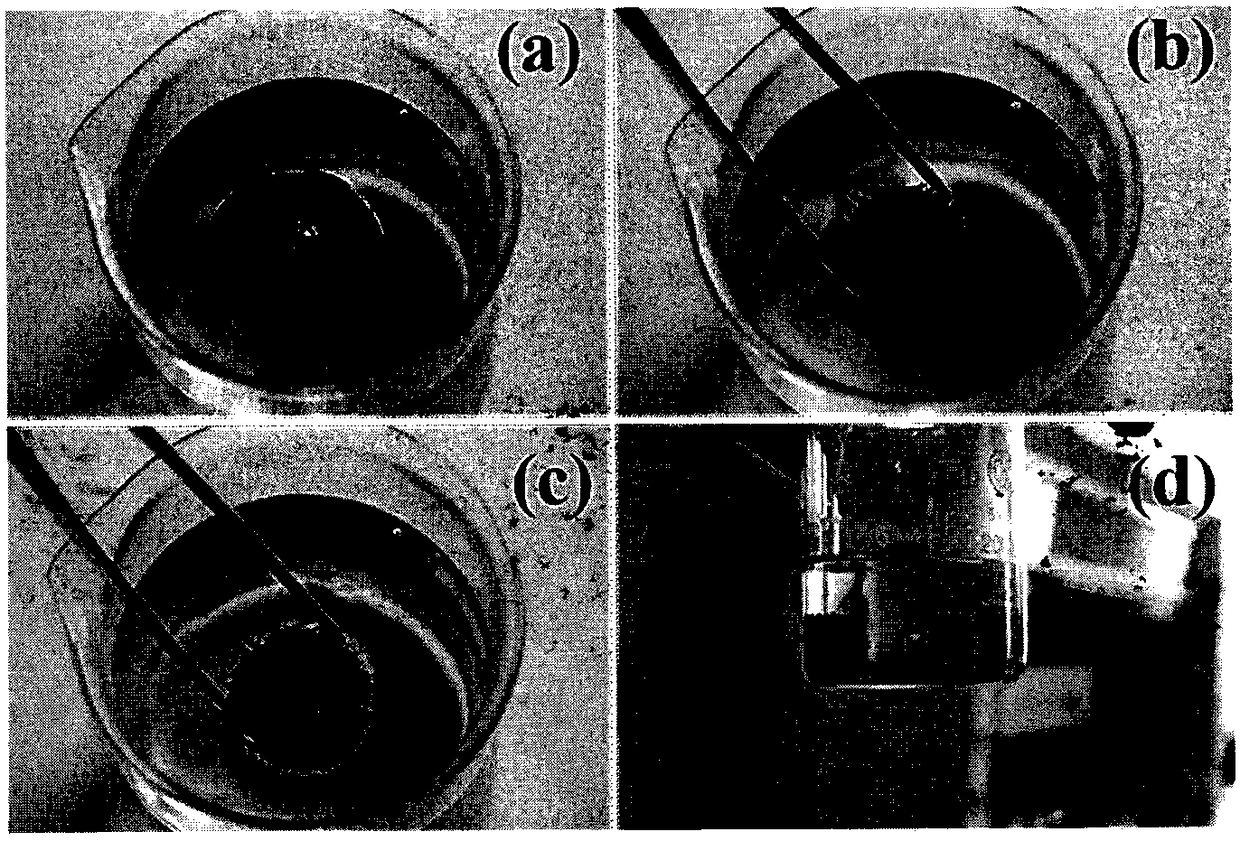

Image

Examples

Embodiment 1

[0023] Take 1.5g of paraffin oil (stained with Oil Red O) and add it dropwise on the water surface to form an oil film. Take a sweetgum cone that has been carbonized (heating rate is 10°C / min, stay at 400°C for 1 hour, and stay at 600°C for 2.5 hours) and put it into the edge of the oil film. After putting in the carbon balls, the oil film shrinks rapidly and the carbon balls are inhaled. After the oil film is completely inhaled, take out the carbon ball and immerse the ball in n-hexane to desorb the paraffin oil.

Embodiment 2

[0025] After carbonization (heating rate is 10°C / min, stay at 400°C for 1h, and stay at 600°C for 2.5h), immerse the sweetgum cones in paraffin oil, take them out after a certain period of time, and stay in the air for 1-2 minutes, Weigh it. The oil absorption mass is the weight after adsorption minus the initial carbon sphere mass, and the oil absorption is the ratio of the oil absorption mass to the initial mass of the sphere (g / g). The carbonized liquidambar cones have an adsorption capacity of 2.4g / g to paraffin oil.

[0026] The saturated carbon spheres are put into an organic solvent (n-hexane) for desorption, and the desorption rate is the ratio of the weight of the desorbed oil to the weight of the oil absorbed. The weight of the desorbed oil is the weight difference of the ball before and after desorption. Carbon spheres can be completely desorbed within 5 minutes, and the desorption rate can reach 99%. The desorbed spheres were dried at 60°C, and the desorbed sphe...

Embodiment 3

[0028] After carbonization (the heating rate is 5°C / min, stay at 300°C for 1h, and stay at 600°C for 3h), dip the sweetgum cones in turpentine, take them out after a certain period of time, stay in the air for 1-2 minutes, and weigh them. Heavy. The oil absorption mass is the weight after adsorption minus the initial mass, and the oil absorption is the ratio of the oil absorption mass to the initial mass of the ball (g / g). The carbonized liquidambar cones have an adsorption capacity of 1.9g / g for turpentine. After 10 cycles, the carbon spheres basically maintain the same adsorption and desorption capacity (1.89g / g), which has excellent recycling performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com